|

Jan.

2002 Vol. 223 No. 1

Feature Article

|

DEEPWATER TECHNOLOGY

Surface BOPs: Background, implementation program

hell

International E&P’s Graham Brander discussed: Shell’s exposure to use of these systems in the

calmer waters of Southeast Asia; basic designs of Surface BOPs (SBOPs) used by Shell; and the implementation

program planned for the U.S. Gulf on a 3rd-generation rig for 2002. hell

International E&P’s Graham Brander discussed: Shell’s exposure to use of these systems in the

calmer waters of Southeast Asia; basic designs of Surface BOPs (SBOPs) used by Shell; and the implementation

program planned for the U.S. Gulf on a 3rd-generation rig for 2002.

Background in Southeast Asia, benefits. In

mid-2000, Shell Indonesia participated in a two-well project using a SBOP system on Transocean’s

Sedco 601 semi. These two successes significantly increased interest in the system. Then, in mid-year

2001, the Shell operating unit in Brunei (BSP) used the semi for a three-well project using the frame-type

SBOP. And in the 3rd quarter of 2001, the Shell operating unit in Malaysia (SSB) used the Stena Clyde

semi for a two-well project using an alternative (unconstrained) SBOP system.

Results from these operations with mild metocean

conditions have produced data that allows this technology to be taken to other areas of the world. Principal

benefits from the use of SBOPs are that it:

- Potentially unlocks significant cost savings per

project by increasing the operating envelope of existing 3rd-generation rigs to that dominated by 4th and

5th-generation rigs. There is, therefore, the potential to reduce dayrates to $60,000 to $85,000, from

$145,000 to $200,000.

- Allows more efficient operations, i.e., no need to

run BOP to seabed.

Further, it potentially increases the number of

deepwater rigs available. And it increases the number of well projects that can be absorbed into a rig

sequence.

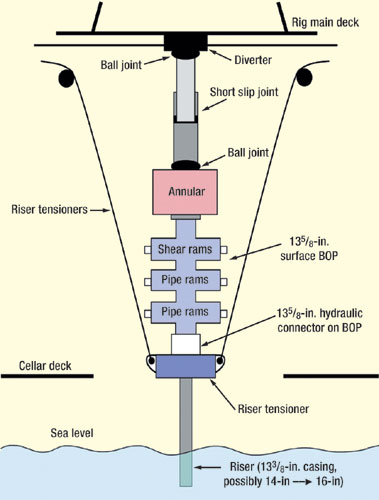

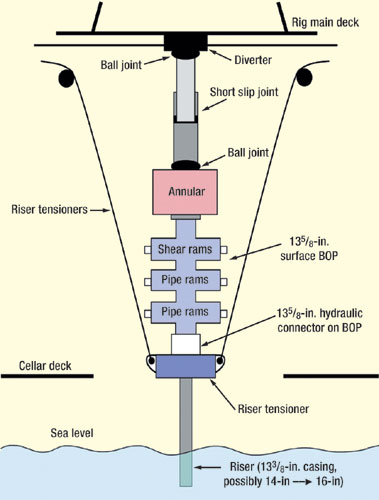

GOM designs, implementation. Fig. 1 illustrates

a laterally unconstrained SBOP design proposed for the Gulf of Mexico. There are several advantages of this

system over other surface BOP designs.

|

|

Fig. 1. Laterally unconstrained surface

BOP design for Gulf of Mexico. |

|

Unlike other systems, it can be transferable between

rigs; i.e., using one system in an area can cut high rig mobilization costs. The system will include a subsea

shutoff and disconnect device that others do not have. And it will be designed for low-drilling-margin wells,

i.e., technically challenging wells.

Prelaid mooring packages will take advantage of

existing prelaid operational experience with one-boat preparation – the GOM will build on this. The

laterally unconstrained SBOP will be more tolerant of severe metocean conditions over the conventional fixed

design. A 16-in. riser capability will also be reviewed within the project’s work scope.

Shell is looking at implementation of an SBOP on a

3rd-generation rig by November 2002. This schedule will require contributions from several project packages

that are being addressed now. These include:

- Subsea shutoff / disconnect devices

- Riser analysis

- SBOP design options

- Mooring analysis

- Rig specifications, and

- Equipment / component specification / verification

guidelines.

Other related studies underway will define: 1) Safety

case philosophy and the well-control package; 2) risk-assessment / management tools; 3) performance-assurance

procedures; and 4) the SBOP management system.

While the Gulf of Mexico is the focus of SBOP

implementation, Shell operating units have commitments for 2002 and beyond for West Africa and Southeast Asia.

They are also studying future use for deepwater operations beyond 2002 off Brazil and in the Mediterranean

area.

|

Shell’s

deepwater program: A broad-based technology commitment |

|

Don Jacobsen,

Manager, Drilling & Completions, Shell Exploration & Production Co. (SEPCo), New Orleans; |

|

Paul Goodfellow,

Drilling & Completions Operations Manager, Shell International Exploration E&P Inc., New Orleans;

|

|

Ken Dupal, Sr.

Staff Drilling Engineer, SEPCo, New Orleans; and |

|

Graham Brander,

Sr. Drilling Engineer, Shell International E&P Inc., Houston. Overviews of their presentations follow.

|

|