Multiphase flowmeters reduce CAPEX and OPEX, enhance flow assurance in unconventionals

The need for monitoring individual well production is becoming increasingly essential in unconventional field operations. The drivers behind this need are related primarily to accurate reporting for production allocation between wells. In North American unconventional operations, the main driver for meter-per-well flowrate monitoring is accurate per-well production accounting, due to the complexity of landowner interests. As operators seek better ways to account their production, they see several additional benefits from replacing traditional separators with multiphase flowmeters for produced fluid measurement.

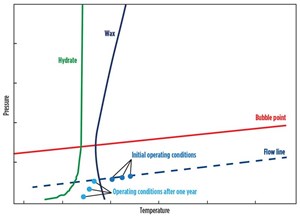

Specific flow assurance challenges can be encountered in unconventional field production. The use of multiphase flowmeters can help diagnose and mitigate such challenges. Early detection is a critical factor, but more importantly, proper understanding of the impact of the commingling of fluids produced from various wells in the same pad can allow optimization of the chemical injection to mitigate the issue. The nature of fluid heterogeneities, high variability of production conditions, and variability of the production life of various wells, co-produced in the same pad and commingled into the same flowlines and process system, lead to unexpected flow assurance issues in shale oil and gas production.

METERING IN UNCONVENTIONAL WELLS

The industry’s initial development of shale gas, with reasonably dry gas produced at surface, lent itself to the use of traditional electronic gas flowmeters (EFMs) located on individual wellheads. The initial solution consisted of back-allocating the rate from commingled production from various pads. This practice led to poor assignment of production rates and volumes to individual wells.

The next step consisted of installing a small test separator on the well pad and sequentially testing the connected wells. While this enabled some improvements in the production allocation, the major challenge of the high variability of performance between wells on the same pad remained. Unconventional oil wells experience very rapid production decline at an early stage, accompanied with important water cut and fluid property changes. A dramatic increase in the gas/oil ratio can be observed. These variations happen at different times, with different dynamics, on a pad of several wells, making back allocation a challenging task.

The practice of installing a test separator, per well, on the pads has proven to be CAPEX-intensive. This is due to the need for production data gathering on a per-well basis. Operators have found new challenges in managing the right turn-down ratio of measurements on each well, a process that requires constant attention and places timing demands on personnel to service equipment. Furthermore, the very large number of new wells drilled requires a matching number of test separators, adding to CAPEX and resulting in more operational challenges.

In terms of OPEX, maintaining a large fleet of test separators for the sole purpose of metering is an expensive exercise. The control system used to manage the level interfaces between water, oil and gas requires two controllers and two active control valves. Maintaining pressure stability requires an additional controller and control valve. Apart from maintaining pneumatic power at the wellsite, it is necessary to keep continuous control of the operational integrity of the moving parts in the controllers and actuators. Moreover, with unavoidable production of solids during the production period of the well, particularly after choke changes or restart, it becomes necessary to regularly empty the separators as they slowly fill with solids, especially as production rates decline.

Mulitphase flowmeters are a relatively new solution for measuring production and are lighter in terms of installation, operation and financial burden. Each meter is programmed for the phase properties of the well’s production, which enables continuous data measurement. The need for a metering separator is eliminated. From the more-complete flowmeter dataset, an operator can better predict estimated ultimate recovery (EUR) and better manage production from the pad. The first large deployments of multiphase flowmeters in unconventional basins occurred in 2012 and are now gaining traction.

A meter that has been deployed in oil and gas fields for the last 20 years is the Vx* multiphase well testing technology from Schlumberger. Deploying gamma-spectroscopy, the venturi multiphase flowmeter determines flowrates without requiring separation and has no moving parts, Fig. 1. It is the industry’s only multiphase metering technology that measures flowrate and phase fractions at high frequency, and at a single point in the venturi throat. This method ensures repeatable flow rate measurement in any multiphase flow regime and in production fluids ranging from heavy oil to wet gas.

Introduced in 2014, the next generation of Vx technology, the Vx Spectra* surface multiphase flowmeter, has been deployed worldwide, in oil and gas fields, across land, topside, and subsea applications. Its application largely covers the conditions of flowrates encountered in U.S unconventional operations, in terms of pressure range, fluids, gas volume fractions (GVFs) and water liquid ratios. The main benefits are the lack of moving parts and the robust measurement over a large range of GVFs, with a turn-down ratio over 10 for a fixed GVF.

CASE STUDY

Recently, a Texas oilfield operator evaluated a series of options to replace well test separators installed at the pads of each of its wells. The operator sought a cost-effective solution that would provide the metrological performance required to perform field production allocation, while enabling production optimization workflows to enhance well productivity. The operator chose the surface multiphase flowmeter as its solution, based on financial cost drivers, including:

- Reduction of at least 50% in CAPEX costs per well. This reduction had two main components: Simplified pipeline infrastructure at the pads and reduced investment costs for the ancillaries, including space, power and manifolding.

- Reduction of 90% of operating costs related to maintenance.

In addition to capital and operating expenditures, the operator benefitted from the simplified field architecture of in-line flowmetering without separation, with no intrusive parts in the flow path. Another benefit was the ability to gather more dynamic high-frequency information on the wells to drive other production workflows.

After a rapid pre-selection process, the operator began a field trial. A successful trial led to their decision to utilize one surface multiphase flowmeter to test the technology, validate the use case, and confirm the expected benefits. The deployment was broadened by the end of the year, with additional meters and plans to retrofit old facilities and design new ones to accommodate one multiphase flowmeter per well with a bulk and test setup.

The successful initial deployment led to plans for a larger-scale deployment of meters, with a systematic plan to install surface multiphase flowmeters for all new wells in the future. The operator’s existing digital architecture was quickly adapted to manage the additional feed of information from the surface multiphase flowmeters. The data volumes are not excessively high, even with 10-s scanning rates for each of the fluid phases. Raw data are also stored inside the meter for troubleshooting.

The operator’s quick decision made it one of the first operating companies in an unconventional field to fully replace the typical separator metering solution at the pads with surface multiphase flowmeters. Schlumberger management and field delivery personnel were surprised at the speed of pickup and rapid decision-making in such a massive change of operational practice—where there was no prior exposure to the technology.

The rapid technology adoption was possible because all aspects of changing the field practice were carefully planned and efficiently managed. It is notable that this type of decision agility within months versus years is unusual in conventional oil and gas field operations. This is another confirmation that the success of some unconventional operating assets is built on the fast trial/fail/succeed process that the shale business has adopted over the years in North America.

Once field personnel were trained, they conducted their routine activities to operate the surface multiphase flowmeters. The meters perform calculations of oil, water and gas rates, using pre-set properties for each of these phases. This is similar to how separators require input of some of the phase properties to compute rates at standard conditions. In the case of surface multiphase flowmeters, the correct computation of all three phases requires properly setting all the properties of the phases. This requires updates to the meter’s set-up parameters, when fluid properties change during the well life. Field personnel routinely perform these operations to update the fluid references in the meters. They also troubleshoot the meters and keep a high metering uptime.

Remote troubleshooting allows the service technical team to log-in remotely to the meters. This is done, once proper access to the operator’s IT infrastructure has been granted specifically for some limited period to a given, surface multiphase flowmeter. Once the connection is established, the Schlumberger team can efficiently connect and diagnose a given problem at any time, resulting in reduced field intervention.

ONE METER PER WELL—A SIMPLIFICATION TO OPERATIONS

The architecture of the meter-per-well deployment allows for high-quality measurement and is reasonably easy to maintain. One of the usual challenges observed by users of multiphase flowmeters mounted on test manifolds is managing the variability of properties between wells in a single meter. This is normally achieved by loading a catalog of fluid parameters at each well and making sure that the supervisory control and data acquisition (SCADA) system transmits the information to the meter of the well number that is being metered at any given time. This process can be challenging to manage, as it requires a strict operating process and SCADA sequence when shifting from one well to the next in the manifold. This was not an issue in this field deployment, as a meter is permanently associated with a given well.

Fluids produced in unconventional oil fields are highly variable, not only between wells, but also in time. The in-line surface multiphase flowmeters have no concept of what each of the phase’s properties are, as they only “see” by nature the mix of oil, gas and water fluids. A change in one of the fluid properties can be assigned mistakenly to a change of the respective quantities of fluids. These changes in the gas properties are simple to detect and manage in the surface multiphase flowmeter.

SCALING AND PARAFFIN ISSUES

A fundamental measurement of the surface multiphase flowmeter is the differential pressure from the inlet of the venturi to the throat. This measurement provides raw information about the momentum of the flow and is closely related to the mass flowrate of the fluid going through the meter. This measurement is performed with a differential pressure cell, where ports are isolated from the flow by sealing membranes or remote seals. Any error in the measurement of the differential pressure directly affects the flowrate measurement.

Some of the hydrocarbon fluids encountered in unconventional developments in Texas can be prone to deposit waxes and asphaltenes under some production operating conditions. Such a challenge occurred during the field testing, where the presence of wax, asphaltene and scale buildup was observed around the remote seal’s measuring diaphragm surface, which caused data drifting, Figs. 2 and 3. Once diagnosed from the observation of the acquired data files, the seals were taken off to be cleaned. These issues, which are often encountered in untreated wells in the Eagle Ford shale and Permian basin, also potentially affect some of the process equipment.

To permanently address the paraffin issues, the operator implemented chemical injection. The timing and amount of injection can be governed by the raw measurements of the surface multiphase flowmeters; and adjusted to the minimum levels to avoid scaling and other potential issues in the production system. A simple indicator of scaling is the detection of negative differential pressure, when the wells are shut in for other operational causes or a planned period. These indicators provide a simple alarm for potential paraffin buildup. Just recently, a mechanical enhancement to the surface multiphase flowmeter has been implemented to incorporate drain passages to flush the pressure membranes and the passage through the venturi when clogged. This enhances the surface multiphase flowmeter performance and reduces intervention time.

Well Performance Evaluation and Optimization

Surface multiphase flowmeters can contribute to several workflows, improving production and recovery from unconventional wells. The installation of a permanent meter provides early detection of changes in flow regimes from the high-resolution measurement of rates, Fig. 4. The detection of transition between early flow and linear/bilinear flow is also enhanced. The early detection of instabilities and slugging enables tuning the well or early mobilization of a workover rig to install the necessary lift system when the flowing bottomhole pressure does not support stable lift conditions in the vertical part of the completion.

Tracking the onset of rate instabilities is essential to limit fracture damage caused by proppant fatigue induced by repeated stress. It is important to note that the pressure at surface can be reasonably constant during the slugging events because the pressure behavior may be entirely controlled by the back pressure of the flowlines leading to the pad, which is, itself, a function of the first-stage separation of the production facility when chokes are fully opened or operated outside critical flow conditions.

An important factor to be considered in the deployment of the in-line multiphase flowmeter concerns solids management. All solids flow to the production system, unlike when using a meter with a separator in the pads. It is important to ensure that the first-stage process separators will be able to manage the solids coming from the pads. The centralization of the solids management at the asset level can significantly bring down the operating cost associated with this issue.

Continuous and accurate flowrate measurements of individual wells enable the identification and control of fluid blending incompatibility issues. Individual well production may be asphaltene/scale-free, while the commingled flow induces asphaltene/scale formation and deposition.

The availability of a digitized and repeatable stream of phase flowrates enables several data analytic workflows that are essential to the development of unconventional resources, allowing accurate production transient analysis from reliable rate data. High resolution and stability are key metrological features that are provided by the surface multiphase flowmeters, as necessary to the successful completion of these workflows.

The intrinsic, very high stability of the multiphase meter rate measurements and their high resolution (approximately 0.5% in mass rate) allow for an unusually “clean” decline curve. It makes the identification of a traditional flow regime easier and more rigorous. This enables more accurate prediction of EURs and potentially helps with earlier confirmation of parent-child interferences.

If artificial lift methods, such as gas lift, are implemented, the real-time multiphase flowrates enable monitoring the gas injection performance. This determines the optimal injection rates, to increase production, improve flow stability, and make more efficient use of gas lift resources on real measured data and support models calibration. In addition, if the high-frequency multiphase meter rate data are combined with flowing pressure data, more robust analysis to understand the fluid flow in the reservoir—like a rate transient analysis (RTA)—can be performed. Changing operating conditions can be taken into account, and reserves evaluation can be done with a greater amount of confidence as a viable alternative, when a numerical simulation is not an option.

CONCLUSION

The rapid and large deployment of the surface multiphase flowmeters that replaced per-well metering separators greatly simplified the field architecture for the Texas operator’s unconventional oil field. The impact on CAPEX and OPEX is significant. The detailed planning and management of the project from the field to the operational centers greatly sped up this implementation project, thanks to the commitment of the operator’s top management and the efficient organization of change in the field crews.

The technology adoption in the field has been very much in line with the keen interest of the modern field personnel in the digital world. Additionally, the strong, efficient leadership and ownership of this project was made possible through the consolidation of the facilities management and management of automation in a single role.

Several benefits from the management of the fluids to enhanced production workflows have been enabled by the surface multiphase flowmeters, as a result of their repeatability, high resolution, and dynamic measurement performance. These improvements lead not only to lower costs, but also to additional production and the tackling of flow assurance challenges typically encountered in unconventional wells.

ACKNOWLEDGMENT

This article was adapted from paper SPE-196129-MS, “Large deployment of multiphase flowmeters in an unconventional field,” presented at the SPE Annual Technical Conference and Exhibition, Calgary, Alberta, Canada, Sept. 30 – Oct. 2, 2019.

* Mark of Schlumberger

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- What's new in production (October 2023)

- FPSO technology: Accelerating FPSO performance evolution (September 2023)

- What's new in production (August 2023)

- A step-change in chemical injection (August 2023)