The journey to net-zero emissions LNG

It has become clear that achieving emissions targets and meeting the world’s growing demand for power will require a mix of generation from cost-competitive renewables and cleaner-burning hydrocarbons—most notably natural gas. Through 2040, the two are expected to make up 80% of additional energy demand (from today), with gas taking the lion’s share at 43%.

Despite its emergence as a bridge fuel to a future where renewables dominate the energy landscape, the environmental impact associated with producing, transporting and delivering natural gas in the form of LNG to destination markets is being put under the microscope by activists, investors, lenders and regulatory bodies. A critical dilemma that the LNG industry now faces is how it can reduce its carbon footprint and drive the lowest emissions profile across the supply chain.

Siemens is focused on helping existing, and prospective, LNG customers achieve that objective by supplying the most advanced rotating equipment, electrification and digitalization solutions to facilities, and providing financial, technical development, and strategic support to developers and EPCs in the pre-FEED stages of projects. In a move that embodies the primary mission of the newly formed Siemens Energy Inc., we are now taking the next step in decarbonizing LNG by supporting the development of several low-carbon solutions with international oil companies, as well as the world’s first-ever, proposed, net-zero emissions liquefaction and export complex in Louisiana.

PROJECT OVERVIEW

The G2 Net-Zero LNG project aims to achieve something that has never been done before—supply competitively-priced LNG and other products to customers that are produced, transported, processed and exported with net-zero greenhouse gas (GHG) emissions. The project will be the opening chapter of an energy transformation that will profitably produce net-zero carbon products in addition to LNG, such as Ar, CO2, N2, O2, and electricity, using zero-emissions power from natural gas and renewable resources. The availability for sale of the additional low-carbon emission products will provide revenue that is unique to the G2 Net-Zero LNG export complex.

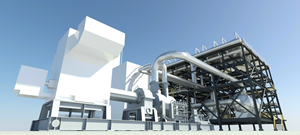

The centerpiece of the project, which is in the pre-final investment (FID) stage, is a 13-million-ton-per -annum (mtpa) integrated liquefaction and export complex, located on approximately 1,266 acres at the mouth of the Calcasieu Ship Channel. The site has previously been approved by the Federal Energy Regulatory Commission (FERC) for construction of an LNG regasification facility, and it offers access to global shipping lanes. Additionally, five interstate natural gas pipelines transit within 20 mi of the site, and a large-capacity interstate CO2 pipeline passes less than 40 mi to the north. It is one of the largest remaining deep-draft locations in the Gulf of Mexico coastal area and is ideally suited for an LNG export facility, Fig. 1.

The G2 Net-zero LNG project is being developed in partnership between Louisiana-based owners and global industry leaders, including Siemens Energy; NET Power; 8 Rivers; EJM Associates, LLC; Denbury Resources Inc.; and Ming Energy Partners LLC. Each of these leaders is committed to the idea that net-zero LNG can be the long-term solution for clean, reliable and affordable energy for the world.

Siemens recently signed a Memorandum of Understanding (MoU) to provide technical and engineering support to G2 Net-Zero LNG, with a focus on identifying and specifying engineering services, project management services, and equipment and technology solutions best suited for the project, Fig. 2.

Driving toward net-zero emissions. To achieve net-zero emissions, the G2 project will leverage a range of highly innovative technologies and processes across the supply chain—from natural gas production at the wellhead, to treatment and transportation, and finally to liquefaction and export.

One technology, which will play a critical role, is NET Power’s novel power system, based on the Allam-Fetvedt thermodynamic cycle. The Allam-Fetvedt Cycle is a high-pressure, highly recuperative, oxyfuel, supercritical CO2 cycle that eliminates the smokestack and makes emissions capture a part of the core, power generation process. Power plants utilizing the Allam-Fetvedt Cycle can attain high efficiencies and are capable of capturing millions of tons of CO2 per year with little-to-no water consumption. The emissions-free power generation also produces valuable petrochemical feedstocks.

The power island at the G2 liquefaction site will be the largest net-zero, natural-gas-fueled, electric power generating system in the world. It will generate over 1,000 MW of electricity and capture nearly 4 million tons of CO2 every year. The captured CO2 from the system will be used and recycled onsite. It will also be sold for a variety of uses (e.g., enhanced oil recovery, concrete production) or placed in permanent storage. A portion of CO2 will be made available to a laboratory at the site that will be dedicated to developing novel processes for capturing and permanently sequestering carbon from the atmosphere. NET Power’s technology also meets the requirements for receiving “45Q” tax credits for carbon capture, utilization and storage (CCUS).

One key benefit of utilizing the emissions-free power system is that it will provide increased flexibility for project financing. The European Investment Bank (EIB), for example, recently announced that it would end funding for fossil fuel energy projects that do not meet an emissions performance standard (EPS) below 250 grams of CO2 per kilowatt-hour (kWh). Although an investment from the EIB for the G2 project has not yet been contemplated, it would qualify for financial support under these current rules. Similar provisions are expected to be adopted by other major financing agencies across the globe.

Another critical technology that may be leveraged for the G2 Net-Zero LNG project is 8 Rivers’ proprietary TarT gas treatment system, which is capable of processing low-cost “sour” gas. The system will capture CO2 emissions and increase natural gas liquids (NGL) recovery. This will ultimately enhance the value of the raw gas stream and provide a competitive cost advantage for G2, when compared to projects that use conventional treatment systems.

As previously mentioned, additional measures will be implemented upstream of the liquefaction complex, to mitigate emissions further. This will include, but is not necessarily limited to, drilling, completions and production equipment powered by net-zero electricity. Other proven technologies for leak detection and methane recovery will be deployed across the supply chain. Where required, carbon offsets for any fugitive releases will be purchased, to ensure net-zero emissions during production and transportation via pipeline to the G2 site in Louisiana.

To enhance the bankability of the G2 Energy Export Complex, a unique, phased development approach will be adopted. Within three years, the facility will generate incremental revenue by selling Ar, N2, and O2, captured by onsite air separation systems. Additional income will be made by selling electricity and CO2 that is captured by the first NET Power station. Within this timeframe, the project will also receive 45Q tax credits for CO2 use and/or storage. LNG exports for G2 Net-Zero LNG are expected to commence by 2027.

Pushing the bound of LNG plant design.The world today faces many difficult challenges. Natural gas—abundant and inexpensive—is set to play a critical role in addressing these challenges. Since 2010, 600 million tons of CO₂ savings globally have been generated, as a result of replacing coal with gas as a feedstock—an amount equivalent to nearly 60% of the annual emissions from all of South America.

For global energy companies tasked with building out the requisite infrastructure to deliver gas to destination markets, decarbonizing the value chain has become a priority, Fig. 3. Together with the world-class G2 development team, Siemens is aiming to leverage our experience and broad LNG expertise to push the bounds of what is possible in this regard and blaze a trail that will enable the industry to drive toward a more sustainable future.

REFERENCES

- https://www.shell.com/promos/download-the-full-lng-2020/_jcr_content.stream/1582140325378/ddcfff9e5f778ee9e8876b3b564e7337599b0d61/lng-outlook-twentytwenty-factsheet-final.pdf

- https://www.shell.com/promos/overview-shell-lng-2019/_jcr_content.stream/1551087443922/1f9dc66cfc0e3083b3fe3d07864b2d0703a25fc4/lng-outlook-feb25.pdf

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Digital transformation: Accelerating productivity, sustainability in oil and gas (November 2023)

- Technological advances increase efficiencies and flexibility (November 2023)

- Volatile organic carbon emissions in oil and gas industry: Impact and mitigation (November 2023)

- Technological innovation delivers transformative product suite to upstream sector (November 2023)

- Executive viewpoint (August 2023)