Fully dissolvable frac plug results in efficiency gains in long lateral completions

In long lateral completions, a new approach to dissolvable frac plugs is overcoming traditional challenges—timely and total dissolvability across full laterals—in various wellbore fluids and temperatures. The advance is enabling long-standing industry goals of interventionless completions, and revealing new efficiencies and design flexibility in wells, where low wellbore pressure and sand returns still require coiled tubing clean-out. In the field, clean-out time with the plug design has been reduced ≤12 min./stage and +12 hr/well.

The SWAGE dissolvable plug, developed by Innovex Downhole Solutions, differs from traditional plugs in its minimalist, expandable design, with fewer components made of a proprietary blend of 100% dissolvable metals. Developed for time-critical, multi-well hydraulic fracturing operations, the plugs provide effective isolation and completely dissolve on a predictable schedule. This reliable dissolvability is a significant advance in achieving interventionless completions, as well as improving the efficiency of coiled tubing operations. Early experience suggests that while coiled tubing can be eliminated with fully-dissolvable plugs, one of the greater applications may be reducing time and risk where coiled tubing is still needed, such as wells where marginal flowback pressure still requires intervention.

THE SEARCH FOR DISSOLVABILITY

Composite plugs are the primary method of achieving zonal isolation in multi-stage fracs. Once the frac is complete, the composite plugs are drilled out, using either jointed pipe or coiled tubing. The removal of the composite plug material is often difficult and may require multiple chemical sweeps and a patient approach. The remaining plug materials left in the wellbore present the risk of sticking the BHA, impeding production, and plugging production tree chokes. Introduced in the 1980s, composite plugs are typically composed of various components, in addition to composite materials. Those components include difficult-to-drill parts made from cast iron, tungsten, ceramic and other materials. The intervention required to remove these materials adds significantly to cost and time.

This overhead was increasingly unacceptable, as plug-and-perf methods became the predominant design for completing long horizontal wells. The expense and risk associated with their drill-out led to development of dissolvable plugs.

However, early dissolvable plugs were more costly and had limited utility, because they were not entirely dissolvable. They still retained many of the same components that made composite plugs difficult to drill out, such as slips with carbide or ceramic buttons. Though functional, the complex design and large amount of material required by these plugs prohibited effective degradation, and ultimately required wellbore intervention to remove the undissolved debris.

In addition, these dissolvable plug designs presented other operational issues. Often, their performance was constrained by the wellbore environment. Even incomplete dissolvability required a specific concentration brine fluid and temperature range. Because these factors are also time-dependent, managing multi-well pad completions to optimize plug dissolvability added to the difficulty and expense.

MATERIALS AND DESIGN INNOVATION

The inherent challenge presented by these early dissolvable plugs was a combination of design and materials. The relationship between the two was as unbreakable as it was undissolvable.

Achieving timely, total dissolvability required a significant departure from both constraints. A novel frac plug, developed by Innovex Downhole Solutions, is a simple three-piece design that expands to the casing wall. Traditional slips and elements—the undrillable parts of conventional dissolvable plugs—are eliminated. Instead, a grit surface on the exterior of the expanded plug acts both as a metal-to-metal seal and an anchoring device. The minimalist design uses 75% less material than traditional dissolvable plugs, which allows it to dissolve more easily under a variety of wellbore conditions.

The design is enabled by an alloy that is both expandable and fully dissolvable. It is the sole material used in the frac plug; there are no elastomers, brass, aluminum, carbide or other materials that have traditionally presented challenges. The proprietary material—a melted metal—provides more consistent parameters and higher dissolve rates than powdered metal. Comparatively, the material also exhibits better elasticity, ductility and toughness, and is more easily customized than typical powdered metal. Variations of the material are used to produce different dissolve times and rates, in specific wellbore temperatures and brine concentrations.

OPERATIONAL COMPONENTS

The SWAGE plug is set with standard industry wireline tools and has no moving external parts, eliminating the risk of pre-setting. After the stage is pumped, and the diversion ball falls off the seat, the plug presents a large bore for flowback, Fig 1. The plug, in 4½-in. to 5½-in. casing sizes, is 8 in. long with an OD under casing drift.

A cylindrical swage body that expands to set against the casing and a donut-shaped swage are included in the limited components. The swage is mechanically forced into the swage body to expand its diameter, anchoring it and providing a seal with the casing ID, Fig. 2.

PERFORMANCE VALIDATION

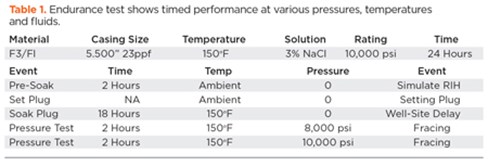

In performance validation tests, the plug was subjected to various temperature and fluid conditions. It qualified to 10,000 psi for 12 hr and 24 hr, depending on material selection, Table 1.

Degradation testing was performed to accurately predict the dissolvability of the plug under typical wellbore conditions. Both coupon and full-scale testing were used to create a predictive model. The dissolve charts accurately predicted dissolvability in various fluids, from fresh water to 3% chloride concentration, at temperatures ranging from 120° F to 350° F. In most common applications, the plug is completely dissolved in three to five days at temperatures ranging from 120° F to 350° F, and in fluids from fresh water to 3% chlorides.

OPERATIONAL EXPERIENCE

In the field, these capabilities reduced or eliminated the cost of coiled tubing intervention to remove undissolved materials. They also avoided bridging and flowback problems caused by partially dissolved materials.

The plug’s 12-to-24-hr working life allowed adequate time for unpredictable operational delays that can occur with multi-stage fracing operations, and its large ID resulted in immediate flowback when desired.

While much of the attention given to dissolvable plugs is focused on enabling interventionless operations, success of the new plug has shown that significant benefits may come from other applications, where intervention is still required. For instance, selective placement of dissolvable plugs can reduce the time and risk of intervention in conventional plug-and-perf operations. Dissolvable plugs also increase efficiency in wells where flowback pressure is insufficient to return proppant. In these common cases, coiled tubing intervention is still required, but reliably dissolving plugs can significantly reduce clean-out time.

FIELD STUDIES

Dissolvability of the SWAGE plug was studied in several completions in South and West Texas. The studies involved a variety of applications in which coiled tubing was used, or where no clean-out was conducted. In some instances, the operator initiated the clean-out before the plugs were expected to have fully dissolved. Nevertheless, drill-out confirmed that the great majority did dissolve. The remaining plugs were dissolved to such a significant extent that it was clear additional time would have resulted in fully dissolved plugs. In these instances, the plugs were so easily drilled that coiled tubing time was reduced considerably and it was more effective, especially in difficult toe sections, Fig. 3.

DISSOLVABLE VS COMPOSITE

In a Midland basin well, in the Permian basin of West Texas, 23 of the dissolvable frac plugs were run at the heel of the well, with an additional 23 composite plugs run below to TD. Within 48 hours after the frac, coiled tubing was used to clean out the lateral and confirm that the frac plugs had dissolved.

Of the 23 dissolvable plugs, only three were tagged. The drill time for the three that had not completely dissolved averaged less than 1.5 min., indicating that the plug was mostly dissolved and would have dissolved fully, given the full-time period. With the dissolvable plugs, the time to drill through the plugs, and wash sand and debris, averaged 14 min. per stage, compared to 27 min. per stage for the composite plugs. Less drill and wash time reduced the overall cost of the intervention, Fig. 4.

WITHOUT CLEANOUT

The dissolvable frac plugs also were used for the full lateral of a Delaware basin well, where no cleanout was planned. After the frac job, the plugs were soaked for three days while rigging up flowback equipment. The well was producing at normal rates 36 weeks after the initial installation, indicating the plugs had fully dissolved.

PAD COMPLETIONS

In a three-well pad completion using 24 SWAGE plugs per well, 64 of 72 plugs were 100% dissolved at time of drill-out. The remaining eight plugs were tagged with a drill-out of less than 2 min., each. Use of the dissolvable plugs on the three-well pad eliminated over a full day of coiled tubing operations, which also allowed for the wells to be put on production sooner.

FULL LATERAL COMPARISON

A West Texas comparison of drill-out operations in full laterals placed 40 dissolvable plugs in one well and 40 composite plugs in another. The 10,000-ft laterals presented a challenge to reach the end of the well with coiled tubing. The dissolvable plugs allowed for faster travel time and eliminated drill-out time. Coiled tubing time for the last 15 stages was only 4 hr versus the 9 hr required with composite plugs.

The time reduction and ease of operations demonstrated that a lower-cost drill-out BHA could be used in the future. Mitigating mill-out operations and reducing debris made it possible to consider a lower-rate BHA with only wash nozzles for sand management.

The savings were particularly significant when applied to the full frac program. The operator typically completes and drills out 12 wells per month. Saving 12 hr/well equates to six drill-out days for a significant cost reduction. In addition, the dissolvable plugs mitigated sticking risk by reducing the amount of debris.

CONCLUSION

Tests and field applications have shown that a frac plug design, using just a few high-strength, fully dissolvable components, provides a dependable, durable and cost-effective solution for temporary zonal isolation during stage fracs in both horizontal and vertical wells. The SWAGE frac plug installations demonstrate that the simple design dissolves predictably, making it possible to achieve the industry goal of eliminating drill-out. Significantly, in applications where intervention is still required, the fully dissolvable plug also greatly improves drill-out efficiency and reduces associated risks. ![]()

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)