Proper timing is critical to increase fracture stimulation effectiveness

In pursuit of the optimum fracture treatment, experts in geology, petrophysics, geomechanics and reservoir engineering have made great strides in understanding field structure and reservoir heterogeneity. Quantifying the key drivers and primary controls on fracture performance is crucial, because they are the framework that define the success or failure of all fracture stimulations. Reservoir characteristics, lithology and stress state properties are the “law of the land.” We must fully understand all these variables to optimize fracture stimulation.

In spite of the tremendous amount of effort and expense by operators and service companies, the question is, why is only 60% or less of the reservoir contributing to production?

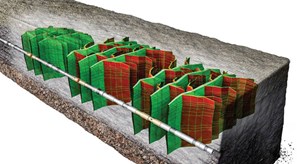

The understanding of tectonic stress regimes and rock strength are factors that certainly influence success; however, from the moment hydraulic stimulation begins, the static snapshot of reservoir conditions changes, so it becomes necessary to extend the framework of our consideration to account for how the rocks will respond to fracture stimulation in the dynamic altered state, in real time, Fig. 1.

NET PRESSURE CONCEPT

To begin the discussion of the dynamic stress state, and to explore the numerous ways that it can impact the effectiveness of a well completion, an explanation of net pressure is useful. Net pressure is the force applied to the formation that exceeds the minimum tectonic stress. This applied pressure is the most basic requirement for creating a hydraulic fracture. For example, if the minimum tectonic stress is 7,200 psi, and the bottomhole pressure during hydraulic fracture propagation is 8,200 psi, the net pressure applied is 1,000 psi. In comparison to total pressure, this number is quite small. This small number is the relatively narrow margin of the total pressure, where we cause a fracture to propagate, and so managing that excess energy to generate fractures defines our level of success.

After the rock is hydraulically fractured, a modal change in formation behavior has been introduced. During pumping, when net pressure is at its maximum, and we add fluid and proppant to the fracture, the physical circumstance that we have imposed on the reservoir is a mode of fracture propagation. The reservoir and the pressure inside it must change to accommodate the added volume.

When fluid delivery to the fractures stops, propagating ends and fracture closure begins. Thus, pressure inside the hydraulic fracture is transmitted to the surrounding rock matrix, as the reservoir transitions from maximum energy state to a lower condition. The dissipation of stress occurs by fluid leak-off to pores and natural fractures, and further deformation of the formation. The time required for this process, and the effect it has on the rocks around the fractures, varies according to the specific rock properties and the proportion of energy (or net pressure) that each leak-off mechanism dissipates.

Reservoirs that are more prone to fracturing as a mechanism to redistribute stress will experience shear failure and higher pressure leak-off rate near the hydraulic fracture. In this case, stress dissipation will occur faster, and the effects will not extend as far away from the fracture face. In contrast to reservoir conditions, where energy is lost to the created fracture network, and reservoirs where new fractures didn’t form, propagation of stress through the solid rock extends further in distance.

Both processes serve the same purpose, which is to release net pressure energy and redistribute it more evenly across the reservoir. This is known as the relaxation process. Through these observations of propagation, closure and relaxation, we see that there are several processes occurring in the rock volume, as its responds to the elevated energy state.

The reservoir is in a state of flux, and the altered stress state has far-reaching effects. In other words, the elevated stress state has a shape. Not a planar shape, as fractures are commonly illustrated, but rather it is a volume whose shape is dictated by the mechanical properties of the rocks surrounding the hydraulic fractures, and their interaction with the initial tectonic stresses.

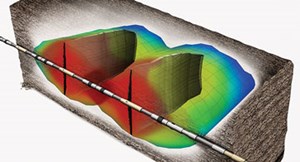

These shapes have been coined “stress shadows,” and the phenomena that result from them during hydraulic stimulation has become a focal point for researchers in the industry,

Fig. 2. Recent geomechanical research1–3 has evaluated how these stress shadows influence fracture growth. Observations from numerous plays show:

- Differential stimulation effectiveness between entry points in individual stages

- Non-uniform fracture growth

- Failure to initiate fractures

- Delayed microseismic events in the reservoir.

These observations show how stress shadows can influence operations, and cast doubt on geomechanical models built solely on static measurements.

- At one end of the spectrum, we can observe wells that achieved a fairly evenly spaced distribution of fractures after stimulation, with little adverse reaction from the resultant stress shadow.

- In the middle, the statistical majority of well completions, a significant portion of perforation clusters fail to initiate fractures or are under-stimulated as a result of stress shadow interactions.

- At the far end, there are wells where the pressure required to initiate a fracture, increases from stage to stage, until a complete failure to break down the formation occurs and no fractures are created. This is the most extreme case of stress shadow interactions.

To explain failed fracture events and variability in formation behavior, it is necessary to address the dynamics of the stress that we have introduced to the rock volume as a function of time.

DYNAMIC STRESS MODEL

Stresses in the reservoir during hydraulic stimulation change over time. First, through the understanding of net pressure, the amount of irreversible damage (fracturing) that hydraulic stimulation can cause is related directly to the rate of stress application. Secondly, the volume of rock that is subject to the influence of discrete stress concentrations or stress shadows around hydraulic fractures will continue to deform, as a function of the rate of net pressure decline (leak-off) and the relaxation processes.

This statement is not simply about pump rate during fracturing of an individual stage. Rather, it considers the operational time devoted to pumping additional fluid volume, and whether or not the operations do so continuously from stage to stage.

Using the concept of an elevated stress state that loses energy over time, evaluation of stress interactions can be done by relating it to rock deformation processes. The efficiency with which a frac stimulation is conducted has a direct geomechanical impact on the ability to generate new hydraulic fractures and cause slip along natural fractures in the surrounding rocks. By combining stress state dynamics over time, and the altered stress state’s effect of pushing rocks toward their failure limit, we can predict the effects of completion timing on frac distribution.

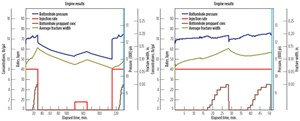

Dynamic model applied to completion strategies. By applying the concept of a dynamic stress state as it relates to the operations timeframe, it becomes obvious there is a difference in our ability to generate complex fracture networks, due to inherent timing discrepancies between various completion strategies. We can observe these differences by comparing a plug-and-perforate completion, and a sliding sleeve continuous pumping operation.

For the plug-and-perf case, after perforating the casing for the treatment stage, fracturing fluid is pumped into the reservoir, forcing it to accommodate the liquid and proppant. This manifests as a fracture. Added net pressure along the fracture face also induces a stress shadow that extends out into the surrounding rock. The stress is not static—it is being transmitted into the rock matrix surrounding the fracture, and dissipating via leak-off and strain of the rocks.

At this point in the operational sequence of a plug-and-perf completion, the energy state is at its maximum. As soon as pumping stops, fracture closure and stress relaxation begin. Wireline operations, required to prepare the well for the next treatment stage, are now underway. During this time, energy is being lost from the fracture system, allowing concentrated pressure to dissipate throughout the reservoir.

In contrast, for continuous pumping completions, the sliding sleeve is opened in the first stage, and hydraulic fracturing is initiated by the same means as in the plug-and-perf completion. Proceeding to the treatment of stage 2, the actuation ball for the next stage is delivered without stopping the pumps. Since the operation is continuous, the net pressure decrease that occurs between stages 1 and 2 is minimal by comparison, Fig. 3.

These operational differences enable us to manipulate the stress state. In stage 1, the stress state is at a maximum. In stage 2, fractures are created so that the stress shadow interactions acting on the rocks between the fractures are inherently greater in magnitude. Stress relaxation that would have occurred during wireline operations is avoided, and the impact of the energy state on the reservoir is maximized.

TIMING FOR RESERVOIR CONDITIONS

Recognizing this fundamental difference, we now need to ask, is it better to impose as much stress as possible and operate in the rapid timeframe, or will the high stress negatively impact the additional fractures we are trying to generate?

For a body of rock with a low failure threshold, there may be a tendency to initiate a complex fracture network under elevated stress conditions. Since the fluids injected during the fracture stimulation cannot move easily through the porous medium, the only mechanism available to accommodate this additional fluid volume is for the rock to break. In this case, the benefits of added fracture complexity will lead to improved drainage efficiency through more complex fractures.

For naturally fractured reservoirs, operating in the timeframe, where stress is elevated, can be tremendously beneficial. Rapid stimulation will maintain a stress state where slip on fractures will occur to a larger degree, thereby improving the ability of the main hydraulic fracture to drain fluids from the fracture network around it during production. Several case studies have documented this phenomenon. Compelling evidence that this difference in energy state occurs at the field scale is outlined in an SPE paper.4

In the case of clay-rich shale formations that have the ability to transmit stress over greater distances, fracture growth in successive stages can be negatively impacted. Thus, relaxation of the stresses at work will likely be beneficial.

In closing, we can see that the “law of the land” includes a dynamic stress state that is caused during hydraulic fracturing. This influences how effective the stimulation of the next stage is going to be. Too frequently, our efforts in modeling reservoir behavior ignore the time between each fracture stage and the energy loss during that time, and the result is sub-optimal. Recognizing the interactions of the dynamic conditions, as they relate to rock mechanics and relaxation mechanisms over time, is a means to increase success in hydraulic fracturing operations. It also could be an ideal way to increase the amount of reservoir contributing to production, well beyond 60%. ![]()

REFERENCES

- Ghassemi, A., “Impact of fracture interactions, rock anisotropy and heterogeneity on hydraulic fracturing: some insights from numerical simulations,” American Rock Mechanics Association, June 2016.

- Peterson, N. A., M. Mehle and Y. Aimene, “Geomechanical modeling of time-dependent strain in the Bakken and implications of stress shadow interactions between hydraulic fractures,” Unconventional Resources Technology Conference, July 24, 2017.

- Bunger, A. P., and G. Lu, “Time-dependent initiation of multiple hydraulic fractures in a formation with varying stresses and strength,” SPE paper 171030-MS 2014, Oct. 21, 2014.

- Reimer, J., M. Ng, B. Dusterhoft, B. Birkelo and B. Hlidek, “Comparing open-hole packer systems with cemented liner completions in the northern Montney gas resource play: Results from microseismic monitoring and production,” SPE paper 174955-MS, Sept. 28, 2015.

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)