Energy Issues

I have mentioned human factors engineering (HFE) more than once on these pages. That’s because it is a perennial topic in my mind, due primarily to the fact that I don’t—or didn’t—think it had been defined well enough to be used reliably. That may be changing.

Through the good offices of my friend and former cohort in crime, Judy Murray, I now have a much more refined understanding of HFE, provided by Kevin McSweeney of ABS and Chason Coelho of the ABS Group. According to McSweeney and Coelho:

- Human error causes 60% to 80% of mishaps and catastrophic events, often with large public and environmental consequences;

- Reduction of human error reduces costs and prevents losses while improving safety, operability, maintainability and resiliency of the system;

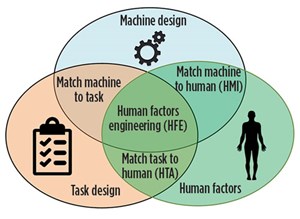

- HFE is a multidisciplinary approach to the design and optimization of complex, tightly-coupled systems, such as those in aerospace, petrochemical processing, oil and gas E&P, transportation, and offshore marine operations, among others.

Implementation of a successful HFE program addresses both the well-being of humans and optimal system performance (focused on efficiency, reliability, availability and maintainability). The goal of an effective HFE program is to erase error-provocative situations through empirical analyses to determine where key mistakes can be made, and then try to design out the potential for human error.

That analyses look at key issues, primarily manning issues, such as the job definition, who is manning the position, and where the work is located with relation to other humans and/or systems. Results of these analyses can identify whether there are right actions but wrong procedures, and wrong actions but right procedures. HF engineers within the management team then try to engineer out hazards by substituting procedures or personnel.

While the HFE process discussed above makes very good sense, it often fails in implementation due to a number of issues. What follows is a discussion of the hazards that HF engineers may try to engineer out.

Human fatigue results from frequent and repetitive tasks, and vibration and noise from work operations that disrupt rest patterns. Additional factors include inadequate lighting that hastens fatigue, and increasing workloads, especially in response to hazardous incidents.

Legacy systems. These systems, which have outlasted their functionality, exist all over the oil patch, especially in computerization. In an ideal world, computer systems would be refreshed continuously, but there is rarely an appetite to carry out work that is seen by executives as not adding value. As a result, the interwoven jumble becomes operationally unstable; cannot create new products or services; and is unresponsive to regulation changes and cyber-attacks (“Legacy systems are problems for boardrooms not computer geeks,” Financial Times, Jan. 31, 2017). Their existence is a testimony to the reluctance to spend money upgrading systems.

That reluctance also can be applied to mechanical systems. In what was one of the better explanations I have heard, Chason and Kevin described an example from the 1990s in which a super-major was looking at lifeboat design. The question of lifeboat capacity came up, as did the question of “how big is Bubba’s butt?” As it turns out, Bubba’s backside in the 1990s was bigger than his father’s backside in the 1970s, when the lifeboat was designed. As a result, the 40-man lifeboat would only hold 32 properly seated individuals. But the classification as a 40-man lifeboat was retained.

And then there is the issue of corporate culture, where the reluctance to spend money on upgrades is complemented by the idea that “we have always done it this way and it works just fine.”

Automation, and resulting reduced manning, are also contributing to failures in HFE implementation. Function allocation analyses should identify things done better by computers, and those things done better by humans. These allocations should be done with recognition that automation has reliability issues, and that automation biases foster a decreased ability to cope with automation failures.

Human issues. Finally, HFE implementation can be impacted by human issues, especially in light of the expanding diversity of the world’s oil and gas workforce. These include, but are not limited to:

- Language issues, especially the failure to use the same words to explain the same thing, which may lead to failures in communications;

- Gender issues, as the workforce expands to include more women;

- The expansion of cell phone usage at inappropriate times;

- The growth of hazardous attitudes, including “done it before,” “I don’t need to listen to him/her,” and additional iterations of machismo.

While HFE is much broader, and more complicated, than this explanation, I hope it puts the discipline in some perspective. Stay tuned. I think the HFE field will expand dramatically. ![]()