P&A retrieval operation enhances long-term well integrity

Well integrity is dependent upon the safe, reliable containment of all well fluids throughout the life of a well, including after decommissioning. Operators are looking constantly for the safest, most efficient methods. They want to be one step ahead of the game with better technologies and cost-saving solutions, when it comes to plugging and abandoning (P&A) wells, regardless of condition.

As the industry recovers from the downturn, operational efficiency, prompt results, and cost-savings are of utmost importance. Challenges associated with improving and maintaining well integrity are further complex, due to the industry’s current cost-constrained condition.

P&A CASING RETRIEVAL SYSTEM

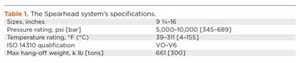

To help operators successfully address these challenges, Archer has developed the Spearhead plug system. This advanced plug system is designed to withstand increased hang-off loads or pull forces, which, in turn, boosts the overall efficiency of P&A operations, Fig. 1.

In addition, this new technology helps to reduce rig site handling and improve safety standards on the rig. Many plugs are limited to pressure testing from above only, but the new design enables pressure testing from both above and below the plug by the use of a ball valve that can be opened and closed as many times as required, Table 1. With this capability, the ball valve capability can be opened and closed as many times as required.

Typical applications for the new plug system include P&A prior to sidetrack, permanent P&A, barrier plug, and temporary suspension.

This new type of plug system is unique, in that operators can combine two or more operations, using it as an anchor before, or after, it has been set as a barrier. The Spearhead plugs are based on Archer’s Lock and Spartan technology. The latter, which fulfills ISO 14310 (V3 to V6) certification requirements, was engineered specifically to be a simple, cost-effective plug solution, with the same benefits as the former’s family of plugs. The focus of these plugs is to deliver protection for short-, medium- or long-term well suspensions.

The company’s plugs and packers are made to provide cost- and time-savings for a wide range of applications, including managing well integrity, emergency hang-off of a drillstring, securing well suspension, plug and abandonment (P&A), and pressure testing.

CASE STUDY

The Spearhead plug system has proven to be a time- and cost-saving plug solution for a major operator, saving 54 hours of rig time during a three-well, P&A campaign. This international operator had planned a six-well plug-and-abandonment (P&A) campaign in the North Sea. The original plan was to cut, pull and lay down more than 4,000 m of 7-in. tubing from each well.

The operator intended to continue setting a bridge plug at 2,000 m, then cut the 9 5/8-in. casing above the plug, and finally displace the well to water-based mud. The process of retrieving and handling the tubing is time-consuming and costly. The operator asked for a plug solution that could avoid pulling the entire tubing string and could save rig time.

Archer Oiltools’ P&A solution was to retrieve approximately 2,000 m of tubing and suspend, permanently, the remaining 2,000 m of tubing below the plug. When the plug and the tubing were run in hole (RIH), a casing cutter was installed above the running tool. The Spearhead, with the tubing below, was set at approximately 2,000 m, and pressure-tested. The 9 5/8-in. casing was then cut above the plug, and all of this was achieved in one run. The P&A operation continued with the retrieval of the 9 5/8-in. casing above the cut.

This operation, utilizing the new plug technology, saw a time-savings of approximately 18 hr for each well. The total savings for this operation were 54 hours for three wells, as well as the cost-savings associated with rig time. The overall safety and risk profile of the operation also was reduced, along with reduced time and costs associated with logistics, transport and handling.

SAVING TIME ON SLOT RECOVERY

In another more recent North Sea operation for slot recovery, the Spearhead P&A retrieval system was used to successfully pull a 10 ¾-in. tie-back, seal assembly and shallow plug in one run. It is estimated that the cost savings for this one-trip operation were up to 3 hr, compared to a conventional three-trip alternative.

Moreover, there were no issues with retrieving the tie-back free with a 115-ton hookload (9-ton over-pull), and pulling the seal assembly did not create any challenges for the plug. This Spearhead was designed to pull as much as 300 tons for this operation. The multi-purpose tool (MPT)/seal assembly was not affected by the pulling of the tie-back.

RETRIEVE TIE-BACK SEQUENCE

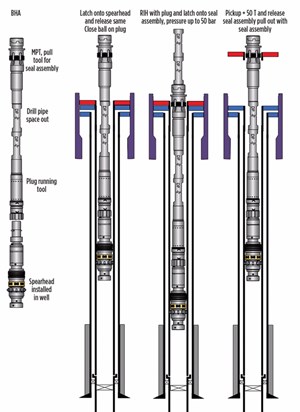

The plug system has the capability of pulling the tie-back or casing when a well is being plugged and abandoned, Fig. 2. It can be used instead of an original spear during P&A operations. A typical operational sequence, as an example, for retrieving the seal assembly and tie-back with the new plug is as follows:

- Latch onto the pre-installed plug system and release same, Fig. 2. Operations also can be done without the plug pre-installed. The plug system has been installed as a temporary V0 suspension plug, prior to being used as a spear.

- Run in hole (RIH) with the plug and latch onto the seal assembly. Pressure up to 50 Bar to activate the Multi-Purpose Tool (MPT), to latch into the seal assembly.

- Pick up approximately 50 tons and release the seal assembly. Pull out of hole (POOH) with the seal assembly and lay out.

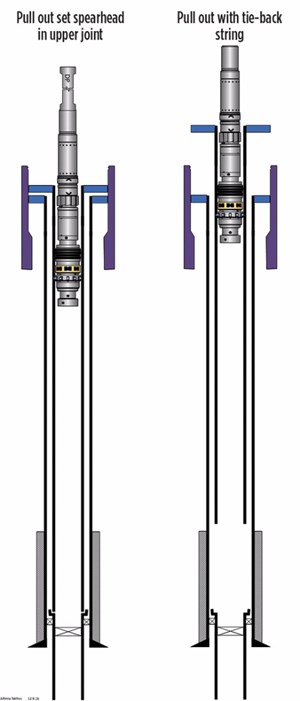

- Pull out and set the plug in the upper joint, Fig. 3.

- Pull the tie-back string free, circulate out the debris, pull out of hole (POOH) with the tie-back string, and lay down the tie-back string.

OTHER PLUG SYSTEMS

Archer’s plugs portfolio also comprises two other new systems—the Vault and the Hunter. Each is based on the Lock and Spartan plug technology.

The Vault dual-plug system enables the installation of two plugs in one run, streamlining plug operations. It allows for running in hole (RIH) and setting two barrier plugs in one single run, instead of two separate runs.

The Hunter tandem plug system was developed for a barrier plug to be run in combination with other downhole equipment, such as wellbore cleaning tools, while being able to withstand high rotation and loads without the plug being set until activated. This plug features a unique benefit that allows the string to be rotated without unintentionally setting the plug.

All three solutions were engineered to reduce rigsite handling, ensure well integrity during operations, suspend wells, and provide safe plugging and abandonment.

INTEGRATED OPERATIONS

In addition to these plug solutions, operators have been calling for more integrated operations to improve safety and reduce persons on board (POB), in addition to real-time responsiveness and economic benefits. A number of North Sea operations utilizing Archer’s plug solutions, have included the services provided by the company’s Integrated Operations (IO) Center for this purpose.

The IO Center, based in Sandnes in western Norway, uses real-time data and communication to enable cooperation between onshore support and offshore teams. Real-time data can be transferred rapidly over long distances, removing the physical barrier between expert onshore support teams and offshore execution.

FUTURE PLUG SOLUTIONS

As operators continue to face the challenges of maintaining well integrity, it is also the company’s ambition to continue developing new plug solutions for safer wells and more efficient operations globally. The firm’s expanding plug portfolio is field-proven worldwide, with more than 2,500 runs. ![]()

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)

- Offshore technology: Platform design: Is the next generation of offshore platforms changing offshore energy? (December 2023)

- 2024: A policy crossroads for American offshore energy (December 2023)