What’s new in well logging and formation evaluation

Profits at oilfield service companies have fallen to their lowest levels in over 12 years. The continued uncertainty in worldwide crude markets, combined with drastic U.S. rig-count declines, suggests further workforce reductions are imminent. In spite of the drastic economic downturn, service providers are still introducing new and updated logging tools and formation evaluation systems.

LOGGING WHILE DRILLING

Wellbore position. The accuracy of methods for determining wellbore position in high latitudes continues to be a concern within the industry.1,2 To address this challenge, Schlumberger and Baker Hughes have developed tools that facilitate well-collision avoidance for use in highly-developed Arctic fields and for offshore applications. To improve MWD accuracy, the fundamental earth geomagnetic models3 have been upgraded, and providers have updated survey methods used with the latest rotary steerable systems,2,4 and incorporated the latest navigation technology.5 A new multi-sensor MEMS-based MWD method, developed at the University of Calgary, can: a) eliminate the costly nonmagnetic drill collars required for magnetometers; b) enable gyroscope-based MWD systems for slim boreholes; and c) provide continuous surveys during drilling.6

Telemetry. Positive mud-pulse telemetry systems are the most widely used. These systems momentarily restrict mud flow through the downhole tool, thereby creating a positive pressure pulse, which then propagates to the surface. In contrast, an annular-venting system creates a negative pressure pulse inside the drillstring, which propagates to the surface. Both types of mud-pulse systems encode the downhole sensor data and transmit them by varying the time between consecutive pressure pulses.

Halliburton introduced a new annular-venting telemetry tool that incorporates improved hardware and software in a field-proven system, and increases the system’s effective data transmission rate. In field applications, the effective data, which are largely a function of signal attenuation in the drilling mud with increasing depth, have ranged between 13.7 to 5.6 bits/sec in well depths between 9,700 ft and 27,900 ft, respectively. This enables real-time delivery of density measurements that are equivalent to recorded images.7

Baker Hughes reported on a new system with increased reliability, achieved through optimized signal processing and enhanced detection of telemetry sequences, which enable real-time transmission of density log measurements.8

NOV’s Intelliserv second-generation wired pipe offers a more robust connection, along with improved inductive coupling and surface electronics. These changes provide more reliable telemetry at a lower cost and improved network connectivity for third-party tools.9

Acoustic logging. Weatherford’s azimuthal acoustic logging tool (CrossWave) uses a unipole configuration to provide high-quality, real-time sonic measurements and azimuthal borehole images of compressional and refracted shear data. The tool has a directionally focused high-output transmitter, a 6-ft attenuator section, an array of six directional receivers, having a 6-in. inter-receiver spacing that are isolated from the body of the collar. The azimuthally focused sensor in the receivers is able to differentiate the slowness of refracted compressional and shear waves from different azimuthal directions around the borehole. X-Y magnetometers track the orientation of the transducers as the drillstring rotates and sort the measured waveforms into 16 azimuthal sectors (bins). The semblance processing and data compression takes place downhole, and a projection image is transmitted up-hole in real time. Compressional- and shear-slowness logs can be computed downhole, or at surface from the coherence peaks of the semblance projections. The tool is available in 4¾-, 6¾-, 8¼- and 9½-in. sizes. The standard tool is rated to 302°F and 20,000 psi. An optional HT tool can function at temperatures up to 329°F, and pressure of 30,000 psi.10,11

High-temperature systems. Service companies have been developing HPHT MWD systems (see 2011 article) to endure extreme temperature and pressure conditions encountered in ultra-deepwater wells, and in basins with high heat-flow. The most recent entries provide real-time direction and inclination surveys; azimuthal gamma ray for well placement; formation evaluation, geological correlation; borehole/annular and pressure while drilling for risk mitigation. Schlumberger’s HPHT MWD service (Telescope ICE) also provides shock and vibration measurements for drilling optimization and damage prevention. It is rated to 392°F and 30,000 psi, and is available in 4¾-in. and 6¾-in. collars.12,13

Weatherford’s HPHT service (HeatWave) includes a neutron-porosity tool in a 4¾-in. collar rated to 410°F, and is the first part of a planned HPHT triple-combo service.14

Spectral gamma ray. Spectral gamma-ray data provides stratigraphic and well-to-well correlation, clay typing and estimates of total organic carbon content. This information is useful for geosteering and reservoir characterization in unconventional and shale reservoirs (see 2014 article). Schlumberger has incorporated a spectral GR measurement in an MWD tool (TelePacer) that is designed to match wireline measurements. It can be configured with an azimuthal GR detector and spectroscopy detector to allow simultaneous real-time acquisition of both measurements.15

Seismic-while-drilling. Seismic-while-drilling tools consist of downhole receivers and employ a surface source. However, by combining seismic sources and receivers in a single device, they can improve seismic resolution and exploration depth. The German Research Centre for Geosciences has developed laboratory and field prototypes of seismic prediction-while-drilling tools. The laboratory prototype is used for tests in dry horizontal boreholes, and for normal temperature and pressure conditions. The wireline prototype is used in fluid-filled vertical boreholes up to 2,000 m, and operates on conventional 7-conductor logging cable. Both prototypes have phased-array source units that allow structural resolution in the range of 1 m.16,17

WIRELINE LOGGING

Depth uncertainty. Depth uncertainty can adversely impact such basic tasks as depth-matching logs with core and, in extreme cases, can result in misplacement of wells and lead to unnecessary re-drills. A recent paper by Harald Bolt, ICT Europe, presents the case for developing industry-standard methodologies for determining wireline depth and verifying the measurement.18 It suggests improvements that operators and service companies could implement for improving depth data accuracy, data calibration and verification of line-length measurement.

Wireline standoff. Gaia Earth Sciences Ltd. has developed a wireline standoff (WLSO) device to mitigate and/or eliminate cable sticking and related fishing jobs during logging operations in high-cost overbalanced deepwater wells, Fig. 1. The device clamps on a cable and provides lift away from the borehole wall. Twelve fins spread the cable pressure on the formation, reducing the potential for key-seating. The WLSO is non-magnetic and does not interfere with the cable telemetry system. The typical application places an array of 20 WLSO’s 45-ft apart, to maintain cable lift over a sticky zone. Installation of a single device takes 2 min. to 3 min. The use of these devices offers an alternative to pipe-conveyed logging in zones prone to cable sticking.19

Acoustic logging. Halliburton introduced a new crossed dipole acoustic service (Xaminer) with a unique isolator design that mitigates tool effects and allows broadband measurement of formational wave dispersion, Fig. 2. The tool design includes two dipole and four monopole sources and a 13-level, 8-receiver azimuthal array. Each set of transmitter firings generates 624 waveforms that are stored in downhole memory. The overall design allows use in both open and cased hole (cement evaluation) provides for a “continuous” depth of seismic investigation when data from the monopole transmitters are sampled and processed together. This assessment is valuable for imaging fractures and bedding planes. The dipole sources can fire down to low frequencies, which enables the tool to log in acoustic slownesses of 1,500 µsec/ft. The tool is configurable for different applications and the logging service hardware is programmable from the surface to address different applications and downhole conditions. The 35/8-in. tool is rated to 350°F and 20,000 psi in boreholes from 4.5- to 22-in. diameters.20,21

Schlumberger has added a slimhole dipole acoustic tool (ThruBit Dipole) to the suite of services offered by its ThruBit division. The 2 1/8-in. tool operates in memory mode in both open and cased boreholes, and provides monopole compressional (P) and shear (S), crossed-dipole shear, and Stoneley measurements. The tool employs a monopole and two crossed-dipole transmitters and a 12-level receiver array. Each level is spaced 4 in. apart and consists of four azimuthal wideband hydrophones aligned with the dipole transmitters. The monopole waveform is obtained by summing the signals recorded by all four hydrophones provided and the dipole waveform is obtained by determining the difference between a pair of opposing hydrophones, which cancels the monopole signal and provided the dipole waveform. The monopole transmitter can fire at a specific low-frequency pulse for Stoneley acquisition. Four sets of 12 waveforms can be acquired from the four basic operating modes fired in sequence. Low-frequency Stoneley-wave measurements in combination with crossed-dipole shear measurements can be used to detect and quantify the orientation and permeability of natural fractures. The tool can log at 1,800 ft/hr and is rated to 300°F and 17,500 psi for use in boreholes ranging from 2 3/8-in. (cased) or 3.0-in. (open) to 9.0-in. diameters.22,23

Borehole imaging. Weatherford has launched a slimhole Compact oil-base mud micro-imager, designed for use in highly deviated and horizontal wells, Fig. 3. The 4 1/8-in. tool has eight pads with nine measurement blades per pad, for a total of 72 sensors. Each of the pads is gimballed to provide optimal borehole contact, and the newly designed blades cut through mudcake to make direct contact with the borehole wall. Each blade features a measurement system that maintains electrical stability within the mud during resistivity measurements. The upper four arms are crosslinked to centralize the tool, and the lower four arms provide six independent caliper measurements that ensure accurate borehole geometry measurements. The memory sub records all high-resolution data. A proprietary image-processer (Reveal 360) uses structural and textural information in the measured parts of the image to reconstruct any gaps between pads, to provide full borehole coverage.24

Nuclear magnetic resonance. Schlumberger commercialized an NMR tool for logging in unconventional reservoirs. The system provides laboratory-quality accuracy, and precision T1 and T2 measurements in low-porosity formations, while maintaining acceptable logging speeds. The relaxation times of fluids in unconventional reservoirs, such as shale oil, heavy oil and tight gas, are much smaller than in conventional reservoirs. Consequently, the hardware and pulse sequences of the new tool have been optimized for measurement of short T1 and T2 components. Modern firmware and electronic components enable faster operation, and the 2-MHz operating frequency enhance measurement sensitivity to T1/T2 contrasts of pore fluids. In addition to the standard T2 logging mode, the new tool operates in short-T1 and long-T1 modes, in which the T1 and T2 measurements are made using the shortest echo spacing of 0.2 msec, which provides a good signal-to-noise ratio, even in low-porosity conditions. The minimum and maximum wait times of 1 msec and 3 sec, respectively, in the T1–T2 pulse sequences provides full polarization of T1 components up to 1 sec. These characteristics result in accurate porosity measurement, even in non-shale sections of many reservoirs.25

CASED-HOLE LOGGING

Cement integrity evaluation. Conventional acoustic transducers are generally unable to provide reliable cement evaluation in cement slurries below 10 lbm/gal, which they sense as a partial or nonexistent bond. Baker Hughes’ latest cement evaluation service (Integrity eXplorer) uses new electromagnetic acoustic transducers to obtain accurate measurements in cement weights as low as 7 lbm/gal, which enables the service to evaluate contaminated, lightweight, and foam cement slurries.26,27,28 The sensors are mounted on six pads (Fig. 4) and physical contact between the pads and casing is maintained by the magnetic force between the two. The pads are designed to make the sensors insensitive to moderate decentralization, allowing tool deployment in highly tortuous wells. The tool can measure cement-bond quality and detect the presence of a micro-annulus in a single pass, in any wellbore fluid environment, without first pressurizing the casing. The service is rated to 350°F and 20,000 psi in casing sizes ranging from 4 1/2- to 16-in. diameters.

Cement curing time. A recent study found that standard laboratory tests for determining cement curing time and compressive strength are not fully representative of those parameters under downhole conditions—curing times can be much longer than previously estimated. Running a bond log before the cement has adequate time to thicken and attain sufficient compressive strength to be detectable by cement-bond tools, can result in measurements that are lower by a factor of two or more. The study suggests that laboratory tests must be redesigned to achieve representative downhole conditions, to accurately estimate the minimum time before logging can occur. In the field it may be necessary to allow the cement to cure longer and also run additional logs over several days.29

Weatherford’s ultrasonic radial scanner service (UltraView) provides high-resolution measurements for cement analysis, casing wear/thickness and fluid properties, Fig. 5. It has been upgraded with a new mud chamber that allows in-situ measurement of fluid impedance while logging, resulting in more accurate detection of channels.30,31 This is an improvement, compared to the conventional method of indirectly calculating impedance from an acoustic slowness measurement. The use of a modified algorithm: a) extends the thickness measurement range, resolution and accuracy; b) improves the ultrasonic scanner’s circumferential and vertical coverage of the real-time thickness measurement, and; c) performs the casing-thickness calculations downhole in real time at normal logging speeds, thereby reducing operational time. Upgraded electronics allow the tool to handle a wider range of casing diameters and thicknesses.32

Pulsed-neutron logging. Modern open hole spectroscopy tools provide high-quality elemental analysis (mineralogy/lithology) and determination of total organic carbon in an open hole. With the appropriate corrections for the presence of casing and cement, they can provide similar high-quality data in cased hole, which can save rig time and avoid borehole stability issues.33,34,35

In addition to faster logging speeds, the integration of advanced pulsed-neutron generators, new pulse sequences, faster detectors and new data-processing methods is allowing the latest generation of PNL tools to acquire saturation profiles in a single run, in contrast to conventional PNL tools, which require a minimum of two runs in different modes to acquire the necessary data.

Using a new pulsing mode, Halliburton’s PNL service (RMT-3D) can acquire data needed for determining three-phase saturation in a single run, with only a modest degradation in saturation accuracy.This new 2 1/8-in. diameter, multi-detector service is designed for casing inner diameters between 2 3/8 in. to 16 in., and is rated to 325°F and 15,000 psi, with a high-temperature option rated to 400°F and 18,000 psi.36,37

Schlumberger’s advanced open hole neutron-spectroscopy service (Litho Scanner) (see 2013 article) uses a new processing method to obtain oil saturation from the TOC spectroscopy determination and porosity.38 The service also provides lithology, matrix properties and hydrocarbon volume in a single logging run, at speeds up to five times faster than a single carbon/oxygen acquisition pass from a conventional PNL device.33

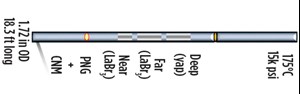

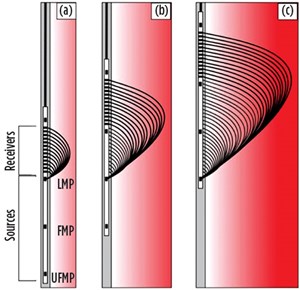

Schlumberger’s new through-tubing (1.72 in.), multi-detector PNL logging system incorporates new high-temperature components and processing techniques. In contrast to the open hole tool, which has only one LaBr3 scintillation gamma-ray detector, the through-tubing logging system has two LaBr3 scintillation GR detectors (near and far), a yttrium aluminum perovskite scintillation GR detector (deep), and a compact neutron monitor to provide more effective normalization of the PNG neutron measurement, Fig. 6. The tool has two primary logging modes: 1) the gas-sigma-hydrogen index (neutron porosity); and 2) the inelastic and capture mode. Spectroscopy data can be acquired in either mode. The service introduces a new standalone gas measurement based on the fast-neutron cross section that is independent of neutron porosity and sigma formation properties. The system can log four times faster (400 ft/hr vs. 100 ft/hr) than a single carbon/oxygen acquisition pass from a conventional PNL device. A corrosion-resistant housing allows deployment in hostile CO2 or H2S environments.39

Well integrity. Downhole video cameras provide direct, real-time evidence of borehole obstructions and equipment damage requiring well intervention (see 2014 article). The next generation of these cameras, manufactured by EV Well Diagnosis Company, is designed to operate in temperatures up to 350°F. To ensure prolonged operations at elevated temperatures, the telemetry section employs the latest vacuum insulated flasking technology, and active cooling methods, to pull heat away from the camera sensor and maintain intensity of the LED lighting system. Running time at 350°F is limited to 1 hr, and to 3 hr at 302°F. Picture resolution, LED intensity and tool rotation can be controlled at surface. The 111/16-in. diameter, black-and-white camera can be run on monoconductor, coaxial and multi-line cables, up to 33,000 ft long.40

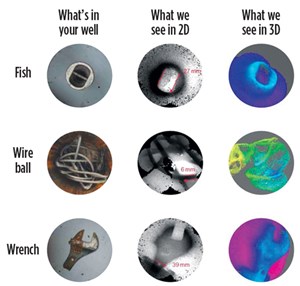

One of the major limitations of downhole video is that it requires clear borehole fluid. In many cases, the operator must first displace effluence before imaging can occur. However, new X-ray technology (see 2011 article) allows visualization of metal objects in all fluids, including produced crude oil and saltwater. Service provider Visuray has commercialized a wireline tool (VR90 Diagnostic Service) that uses a novel technique called fluid-based surface imaging for converting backscattered photons from the fluid into a visual representation of the object, Fig. 7. The logging tool employs a unique downward-focused X-ray source and six-tile detector. Data are combined to create a single composite image, which can be displayed as a 2D depth map or a 3D surface reconstruction. The 3-in. tool can be deployed on wireline, coiled tubing or tractors, and run centered or eccentric. The service is rated to 302°F and 20,000 psi.41,42

Weatherford’s new integrated suite of mechanical integrity services (SecureView) is a quad-combo logging string that provides real-time comprehensive casing and cement evaluation in a single pass, Fig. 8.43The suite comprises four services: a) a digital cement-bond tool (BondView) with a high vertical sampling rate to measure casing-to-cement and cement-to-formation bonding; b) a high-resolution multi-finger caliper tool (CalView) to measure internal casing diameter; c) a magnetic flux leakage casing inspection tool (FluxView) to identify inner and outer casing anomalies, and; d) an ultrasonic radial scanner (UltraView) for determining cement acoustic impedance and casing thickness. ![]()

REFERENCES

1 Chatar et al., 2015, “Anti-collision consideration for Arctic and other high latitude locations,” Paper SPE-173047 presented at the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March.

2 Langaker, I., and Edvardsen, I., 2015, “Continuous inclination enhances TVD wellbore positioning at the Troll fields,” Paper SPE-173878 presented at the SPE Bergen One Day Seminar, Bergen, Norway, 22 April.

3 Beggan et al., 2014, “Improving models of the Earth’s magnetic field for directional drilling applications,” First Break, 32, 49–56.

4 Sugiura et al., 2014, “Improved continuous azimuth and inclination measurements by use of a rotary-steerable system enhances downhole-steering automation and kickoff capabilities near vertical,” Paper SPE-166099, SPE Drilling & Completion, 29(2), 226–235.

5 Hanak et al., 2015, “Assessment of the validity of MWD survey accuracy following multistation analysis,” Paper SPE/IADC-173098 presented at the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March.

6 Chao et al., 2015, “An innovative MEMS-based MWD method for directional drilling,” Paper SPE-175989 presented at the SPE/CSUR Unconventional Resources Conference, Calgary, Alberta, Canada, 20–22 October.

7 Cooper, P., and Santos, L.S.B., 2015, “New mud-pulse telemetry system delivers improved drilling dynamics and formation evaluation data,” Paper SPE-176543 presented at the SPE Russian Petroleum Technology Conference, Moscow, Russia, 26–28 October.

8 Emmerich et al., 2015, “Reliable high-speed mud pulse telemetry,” Paper SPE/IADC-173032 presented at the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March.

9 Craig, A., and Adsit, R., 2014, “Drillstring network 2.0: An enhanced drillstring network based on 100 wells of experience,” Paper SPE-170692 presented at the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October.

10 Mickael et al., 2013, “Real-time LWD sonic semblance image and the step change in LWD sonic applications—a case study from Latin America (Mexico),” Paper SPE-166493 presented at the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, USA, 30 September–2 October.

11 Weatherford, 2014, “CrossWave® azimuthal sonic tool,” brochure WFT-256294.

12 Araujo et al., 2014, “Efficient drilling of ultra-HPHT wells in the Gulf of Thailand, Paper OTC-25392 presented at the Offshore Technology Conference, Houston, Texas, USA, 5–8 May.

13 Schlumberger, 2015, “TeleScope ICE UltraHT MWD service, brochure 15-DR-0013.

14 Perceival, J., 2016, Technology eliminates blind drilling in ultrahigh-temperature environments,” Hart’s E&P Magazine, 89(1), 58–59.

15 Xu et al., 2015, Spectral gamma ray measurement while drilling,” Paper JJJJ, Transactions, SPWLA 56th Annual Logging Symposium, Long Beach, California, USA, 18–22 July.

16 Jaksch et al., 2015, “Validation and calibration of the SPWD-wireline prototype for high-resolution directional seismic imaging in deep borehole hole, Paper BGP02 presented at the Third EAGE Workshop on Borehole Geophysics, Athens, Greece, 19–22 April.

17 Jaksch et al., 2014, “Acoustic communication within the borehole over the drill string,” presented at the First International Symposium on Energy Challenges & Mechanics, Aberdeen, Scotland, UK, 8–10 July.

18 Bolt et al., 2015, “New options for wireline logging depth data quality improvement,” Paper LL, Transactions, SPWLA 56th Annual Logging Symposium, Long Beach, California, USA, 18–22 July.

19 Wheater et al., 2015, “Using wireline standoffs (WLSOs) to mitigate cable sticking,” Paper SPE-174068 presented at the SPE Western Regional Meetings, Garden Grove, California, USA, 27–30 April.

20 Walker et al., 2015, “Logging services: Towards the 3D measurement of formation properties in high-resolution with a continuous depth of investigation,” Paper SPE-175093 presented at the SPE Annual Technical Conference and Exhibition, Houston, Texas, USA, 28–30 September.

21 Halliburton, 2015, Xaminer™ sonic service, brochure H011818.

22 Bammi et al., 2015, “Measuring completion quality and natural fracture indicators in horizontal wells using a new slim dipole sonic memory tool conveyed through the drillstring and bit,” Paper ANI 1.7, SEG Technical Program Expanded Abstracts, 341–345.

23 Schlumberger, 2016, “ThruBit Dipole through-the-bit acoustic service,” brochure 15-FE-15860.

24 Weatherford, 2015, “Compact™ oil-base mud microimager,” brochure WFT-299844.

25 Anand et al., 2015, “New generation NMR tool for robust, continuous T1 and T2 measurements,” Paper CC, Transactions, SPWLA 56th Annual Logging Symposium, Long Beach, California, USA, 18–22 July.

26 Patterson et al., 2015, “Utilization of electromagnetic acoustic transducers in downhole cement evaluation,” Petrophysics, 56(5), 479–492.

27 Baker Hughes, 2015, “Integrity eXplorer cement evaluation service,” brochure 42858.

28 Baker Hughes, 2015, ”Integrity eXplorer cement evaluation service; acquire accurate information to make critical decisions,” brochure 42893.

29 Leslie et al., 2015, “The effect of time on apparent cement integrity—time lapse logging of cement bond logs,” Paper MMMM, Transactions, SPWLA 56th Annual Logging Symposium, Long Beach, California, USA, 18–22 July.

30 Tello et al., 2014, “How much does the borehole fluid affect the cement impedance measurement in ultrasonic canner tools?,” Paper 167784 presented at the SPE/EAGE European Unconventional Conference and Exhibition, Vienna, Austria, 25–27 February.

31 Tello, L.N., and Azuaje, D.C., 2015, “Improving the accuracy of cement bond evaluation by improving the borehole fluid impedance measurement in ultrasonic scanner tools,” Paper SPE-172586 presented at the SPE Middle East oil & Gas Show and Conference, Manama, Bahrain, 8–11 March.

32 Tello et al., 2014, “High resolution real-time thickness measurement of internal and external casing anomalies with ultrasonic scanner tools,” Paper SPE-169631 presented at the SPE International Oilfield Corrosion Conference and Exhibition, Aberdeen, Scotland, UK, 12–13 May.

33 Bustos et al., 2015, “Improving efficiency in mineralogy and saturation determination in open and cased wells with new generation spectroscopy,” Paper SPE-177095 presented at the SPE Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November.

34 Mendez et al., 2015, “Detailed mineralogy and organic carbon detection through casing using pulsed neutron technology—a case study in a carbonate formation (KY),” Paper SPE-175775 presented at the SPE North Africa Technical Conference and Exhibition, Cairo, Egypt, 14–16 September.

35 Perez et al., 2015, “Pulsed neutron through-casing technology for determination of mineralogy and total organic carbon—first case study in the Neuquen Basin, Argentina,” Paper TT, Transactions, SPWLA 56th Annual Logging Symposium, Long Beach, California, USA, 18–22 July.

36 Chen et al., 2015, “A new cased-hole 2-1/8-in. multi-detector pulsed-neutron tool: Theory and characterization,” Paper AAA, Transactions, SPWLA 56th Annual Logging Symposium, Long Beach, California, USA, 18–22 July.

37 Halliburton, 2015, “RMT-3D™ 2-1/8-in. reservoir monitor tool for oil, water, and gas saturations,” brochure H011575.

38 Craddock et al., 2013, “Hydrocarbon saturation from total organic carbon logs derived from inelastic and capture nuclear spectroscopy,” Paper SPE-166297 presented at the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, USA, 30 September–2 October.

39 Rose et al., 2015, “An innovative slim pulsed neutron logging tool,” Paper XXXX, Transactions, SPWLA 56th Annual Logging Symposium, Long Beach, California, USA, 18–22 July.

40 Mukhliss et al., 2015, “First successful implementation of high temperature video camera to identify downhole obstructions in gas wells: A Saudi case,” Paper SPE-172750 presented at the SPE Middle East oil & Gas Show and Conference, Manama, Bahrain, 8–11 March.

41 Safyinya, K., 2015, “X-ray imaging method improves well intervention diagnostics,” Journal of Petroleum Technology, 67(5), 42, 44–45.

42 Visuray, 2015, “Visuray VR90,” brochure.

43 Tello et al., 2015, “Ultrasonic high resolution real time thickness combined with high resolution multi-sensor caliper and CBL tools in a single pass: New mechanical well integrity logging string identifies difficult casing problems,” Paper SPE-172807 presented at the SPE Middle East oil & Gas Show and Conference, Manama, Bahrain, 8–11 March.

- Quantum computing and subsurface prediction (January 2024)

- Machine learning-assisted induced seismicity characterization of the Ellenburger formation, Midland basin (August 2023)

- What's new in exploration (March 2023)

- Seismic and its contribution to the energy transition (January 2023)

- What's New in Exploration: Rocks can save or kill the planet (July 2022)

- Processing of a large offshore 3DVSP DAS survey in a producing well (June 2022)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)