Buoyancy system lands nearly 20,000 ft of 14-in. casing in GOM

Groundbreaking buoyancy landing string (BLS) technology enabled Anadarko Petroleum to run 19,713 ft of heavy-walled, 14-in. casing in a deepwater Gulf of Mexico (GOM) exploration well. In the process, the operator realized potential savings of more than $42 million, while enabling larger casing and more flexibility in well design.

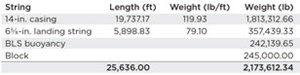

In its inaugural application, in 5,848 ft of water off Diamond Offshore’s sixth-generation drillship Ocean Blackhawk (Fig. 1), the Landing String Solutions (LSS) system removed 242,000 lb off the rig’s critical load path, resulting in an effective, combined landing weight of 2.2 MMlb, Table 1. Without the buoyancy system, the more than 3-MMlb aggregate air weight of the casing, plus the 6 5/8-in. landing string and block, would have reached or exceeded the safe working load of the two-year-old drillship.

The purposely designed, non-metallic buoyancy system represents a straightforward, yet step-change advancement in the industry’s persistent, and exorbitantly costly, efforts to ensure operational safety associated with the heavier casing requirements of deeper and more complex well designs. The new-generation system significantly expands the safety margin of existing hoisting systems, without requiring tremendously expensive upgrades, thereby expanding the safe operating envelope of even load-limited, earlier-generation deepwater rigs.1

Specifically, the LSS buoyancy modules, which are customized for well-specific characteristics with varying density and hydrostatic pressure ratings (Fig. 2), are secured to the heavy casing landing string with proprietary non-metallic fasteners. Once the modules are in place, the system essentially exploits the basic law of physics (Archimedes Principle), in that the effective uplift force intensifies in proportion to increasing water depths with correspondingly longer landing strings and heavier mud density.

HOOKLOAD LIMITATIONS

Globally, excessive hookloads on deepwater wells will continue to present operational challenges, as wells are being designed and drilled to access deeper reservoirs, as reflected in the GOM’s Lower Tertiary subsalt trend and the pre-salts of Brazil, West Africa and elsewhere.

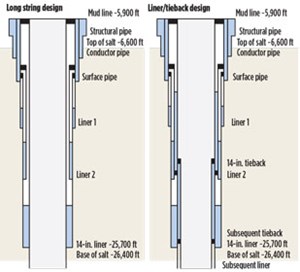

To enhance maximum production and facilitate intervention, optimal well designs call for landing a large-diameter casing string, as opposed to isolating the salt layers with up to two liners and tie-backs. A single tie-back can require several days of rig time, at a cost of $20 million to $25 million.

However, owing to prevailing hookload limitations, operators are often forced to sacrifice ideal well designs. Specifically, landing ultra-heavyweight casing strings is, at times, beyond the safe operating load design of even sixth-generation MODUs. Also, regulations in the U.S. mandate heavy-walled casing for deepwater wells, further increasing both static and dynamic loads exponentially.

Based on complex deepwater well designs, static casing loads, alone, may exceed 2.5 MMlb, but when the associated dynamic loads are considered, the actual weight on the critical load path may surpass the designed safe operating margins of even the most sophisticated new floaters.

With sixth-generation rigs now handling loads at, or near, hookload design capacities, the industry alternatively has announced plans for newer-generation designs and, in the meantime, launched well-documented initiatives to increase existing hoisting capacities.2,3 Concurrent with the tremendously expensive rig upgrades that these heavier loads require, even heavier and longer landing strings are being introduced to accommodate the increasingly heavier casing strings.4,5,6,7 This issue aggravates, even more, the corresponding, operational handling, safety and slip crushing issues of the already strained hoisting systems.

As reflected in the patent,1 it was recognized, early on, that neither new-generation rig designs, or even costly upgrades, could keep pace safely with ever-increasing future load requirements. This recognition inspired the concept of exploiting buoyancy factors to neutralize a considerable portion of the actual landing string weight, thereby providing a much more cost-effective option for enhancing existing hoisting capabilities. Accordingly, even fifth- and earlier-generation MODUs could then be used to land long strings of large-diameter casing, while typically eliminating the need for liner tie-backs.

QUALIFICATION TESTING

The design basis of the nearly seven-year development program for the BLS system required that all components be non-metallic, to eliminate any possibility of potential damage to the subsea wellhead during casing running operations. Moreover, as the system had to be extremely robust and durable, with a minimum 2.0 safety factor, all candidate materials were qualified under worst-case scenarios. As part of the qualification protocol, the non-metallic hinge bolts and collar body clamps were tested, during immersion, in a synthetic-based mud in a hyperbaric chamber to surpass the minimum 2.25 factor of safety at the recommended torque.

Following a series of hydrostatic crush pressure tests, the proprietary material that was selected exceeded all criterion at given service pressures. Furthermore, along with being sufficiently durable to avert any damage during handling and deployment, or in an unlikely side load impact with riser internal weld upsets, the floatation module’s highly impermeable coating material prevents the invasion of wellbore fluids.

TOOL FUNCTIONALITY

While standard for a 6 5/8-in. landing string for range 2 and/or 3 pipe, the buoyancy system nonetheless can be customized for utilization with any size landing string pipe. The modules, each of which are permanently tracked with radio frequency identification (RFID) tags, are designed with an oversized internal diameter (ID) to allow for free rotation, as well as companion thrust collars with nose taper.

The modules were installed on the landing string pipe, prior to shipment to the rig, with various color schemes denoting the predetermined mud density and hydrostatic pressure profiles at different points in the riser. The modules cover all that is necessary for pipe make-up and handling equipment, ensuring no interference with slips, drill pipe elevators and automated tool joint make‐up equipment. The floated-out joints of landing string pipe are loaded into size-specific baskets with containment for any mud spillage.

Simply put, once in place, the high buoyancy lift of the BLS resembles a cork on a fishing line. By relying strictly on the inherent buoyancy dynamics of the deep and ultra-deepwater environment, the technology capitalizes on basic fluid mechanics to allow cost-effective landing of unprecedented casing weights, while, in most cases, eliminating the need for liner tie-backs. Ostensibly, the tool also can neutralize enough weight to safely allow over-pull and use of a floater’s motion compensator during tight hole and ultra-heavy landing operations. Consequently, the construct of the BLS provides operators with the flexibility to design complex wells with heavier associated loads and reduce subsea well construction costs by contracting less costly, but load-limited, fifth- and earlier-generation rigs with hoisting systems that otherwise would be unqualified for deepwater well usage.

Most importantly, however, the effective reduction of extreme loads on a rig’s hoisting system greatly enhances operational safety while running heavy casing on subsea wells. By increasing the effective, safe working load margin of multi-generation MODUs, the landing string system meets and/or exceeds all applicable rig-floor safety regulations. Further, risks of heavy load-induced slip crushing are reduced considerably. The lower effective weights make it reasonable to presume that the motion compensator may be a viable option for landing the casing hanger in a subsea wellhead, on rigs with lower load-rated motion compensators. In operations where heave is observed, employing the motion compensator effectively reduces the risks of equipment damage, thereby magnifying the overall safer working conditions further.

DEBUT WELL RECAP

Following function tests to develop and refine the practical handling procedures on the rig, planning commenced for the system’s first application on Anadarko’s deepwater GOM prospect.

A cumulative 63 landing string drill pipe doubles, at an average length of roughly 85 ft, were prepared at Weatherford’s Port Fourchon, La., bucking facility. The modules were installed at ExPert Riser Solutions’ Port Fourchon yard. Afterwards, the 63 doubles were loaded into custom-designed baskets, in a specific order mirroring the sequence in which they were to be run in hole. The baskets, as well as the specially designed, fit-for-purpose spreader bar and rigging to lift the baskets, were loaded onto the Chouest MV Robert Adams for transport to the Ocean Blackhawk.

On the rig, the calculated air weight of the 19,737 ft of 14-in. casing was approximately 2,370,000 lb, or 120 lb/ft, while the 5,900 ft of 6 5/8-in. landing string added another 467,000 lb or 79.1 lb/ft, Fig. 3. Thus, the buoyed string weight, in combination with block weight, was an estimated 2.41 MMlb.

Adhering to the well-planned LSS and Anadarko procedures developed during the preceding field trial learnings, the landing and eventual cementing of the 14-in. casing string proceeded relatively smoothly and incident-free, Fig. 4. The modules delivered an average buoyancy of 3,800–4,000 lb for each double. Consequently, 242,000 lb were removed from the critical load path and well within the safe operating margin of the sixth-generation drillship.

As illustrated in Fig. 5, the weight reduction delivered by the buoyancy system enabled Anadarko to revise the standard well design to eliminate the need for liners and tie-backs, thus realizing potential savings in excess of $42 million during construction of the deepwater wellbore.

In addition, Frank’s International’s specially engineered and patented 1250-Ton Landing String Spider was instrumental to the success of the buoyancy system, by providing a larger bore pass-through to accommodate the larger floatation module diameter.

Once the job was completed, the BLS doubles were delivered to the ExPert Riser Solutions’ Port Fourchon base, where they were cleaned, inspected and stored for reuse. Notably, upon delivery to shore, the containers within the baskets showed minimal residual mud, indicating that the landing strings were POOH essentially clean. ![]()

REFERENCES

- Von Eberstein, W., Floatation module and method, U.S. Patent No. 7383885 B2, issued June 10, 2008.

- Hendriks, S., L. Claassen and D. Chalkias, “Magellan class drillship: Designing the rig of the future,” OTC paper 26116, presented at Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, Oct. 27–29, 2015.

- Brock, J.N., et al, “Innovative tubular, hoisting, and deepwater rig designs extend hookload envelope to 2,000,000 pounds,” SPE paper 151140, presented at the IADC/SPE Drilling Conference and Exhibition, San Diego, Calif., March 6–8, 2012.

- Plessis, G., et al, “Landing string: Breaking the 2.5 million pound limit,” SPE paper 178777, presented at the IADC/SPE Drilling Conference, Fort Worth, Texas, March 1-3, 2016.

- Flores, V. et al, “Innovative heavy landing system for ultra-deep offshore completion,” presented at the IADC International Deepwater Drilling Conference & Exhibition, Rio de Janeiro, Brazil, March 18–19, 2014.

- Flores, V. et al, “Innovative forging process allows safer and cost-effective, heavy duty landing string for deepwater applications,” presented at IADC World Drilling Conference and Exhibition, Rome, Italy, June 17-18, 2015.

- Simpson, B. et al, “2,000,000-lb landing string developments: Novel slipless technology extends the deepwater operating envelope,” SPE paper 87186, presented at IADC/SPE Drilling Conference, Dallas, Texas, March 2–4, 2004.

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)