|

Until recently, wells targeting thin injectite sands in the North Sea have often failed to deliver reasonable reservoir exposure. These thin sand reservoirs form through post-depositional remobilization and injection along various zones of weakness. On seismic sections, cross-cutting injection “wings” can even look like processing artifacts. As a result, determining the exact stratigraphic location of reservoir boundaries and fluid contacts is almost always subject to uncertainty. Traditional methods of optimizing well placement, under such conditions, suffer from critical limitations.

The Schlumberger GeoSphere reservoir mapping-while-drilling service is capable of revealing formations up to 30 m from the wellbore, and significantly improves the accuracy of landing, reservoir steering and evaluating horizontal wells in complex environments like these. Using the new service, one North Sea operator was able to thread the needle through a thin, sand injectite reservoir—achieving 98% net-to-gross ratio in the first well, and 96% in the second well.

Challenges of targeting sand injectites. Danish oil company DONG E&P operates Nini East field, in the Danish sector of the North Sea, about 3 km south of the border with the Norwegian sector. In 2001, oil was discovered in sands of the Kolga member of the Sele formation. The target reservoir is a thin glauconite-rich sandstone that ranges from 2 to 15 m in thickness, capped by the unstable Sele shale. The Kolga sands were originally deposited as traditional gravity flow and subsequently remobilized after burial. Fluidized sands were injected along pre-existing zones of weakness, such as faults and layers of lower competence.

The operator planned to begin development of Nini East field by drilling two horizontal producing wells and one injector in the Kolga sand. The company’s two main objectives were to establish initial oil drainage, and to gather sufficient information to improve geological understanding of the complex reservoir. More detailed data would enhance subsequent reservoir management decisions and, hopefully, identify additional development opportunities.

While drilling horizontal producing wells in the nearby Nini Main field, DONG E&P had encountered significant challenges targeting the same type of remobilized sand reservoir, using traditional, image-based, geosteering techniques. Its previous wells had been marginally economic, due to net-to-gross ratios below 50% and costly sidetracks. To improve reservoir contact in the new Nini East wells, drilling engineers needed to position laterals high within the Kolga reservoir, but below the unstable Sele shale, while maintaining sufficient stand-off from the oil-water contact (OWC). The operator knew this would be difficult, due to the thin reservoir and the unpredictable nature of its boundaries.

Exploring seismic solutions. First, the company invested in reprocessing and inverting existing 3D seismic data. This effectively improved resolution from about 10 m in the conventional data to about 5 m in the inverted seismic volume. To optimize well placement and ensure commercial success, accurate geosteering was essential. However, based on previous experience, geoscientists realized that traditional methods would not provide sufficient confidence to make timely trajectory adjustments while drilling in this reservoir, given its complex structure and stratigraphy. All existing approaches suffered from certain limitations.

For example, operators typically correlate the logging-while-drilling (LWD) response from the current drilling location with offset data acquired in previous wells, assuming the formation is relatively continuous between them. But that assumption does not hold in highly remobilized reservoirs like the Kolga sand. The effectiveness of traditional borehole image analysis was also limited, because the relative dip and azimuth of the structure identified in such images would not adequately reflect the overall geometry of a reservoir consisting of complex, highly erratic sand injectites.

Another potential solution would be to deploy a real-time bed boundary mapping service, which uses azimuthally sensitive resistivity measurements to image reservoir boundaries some distance from the wellbore—as long as a good resistivity contrast exists between the reservoir and adjoining formations. In Nini East field, however, the Kolga reservoir exhibits very low resistivity (less than 5 Ohm/m). Simulations run prior to drilling indicated that the contrast between the reservoir and overlying shale would reduce the existing technology’s depth of investigation (DOI) to less than 2 m. This would not be enough to image the upper and lower boundaries of the reservoir or structural dip changes observed on the reprocessed and inverted seismic data.

Drilling horizontal wells without exiting the Kolga reservoir would require a much deeper DOI than current bed boundary mapping technology could provide.

Mapping the entire reservoir while drilling. At that point, DONG E&P learned about a new, deep, directional resistivity technology under development by Schlumberger, and decided to field-test it in Nini East field. GeoSphere, the industry’s first reservoir mapping-while-drilling service, was designed specifically to extend the depth of investigation, up to 30 m from the wellbore—about six times farther than existing bed boundary mapping technologies.

The technology’s ability to image so much deeper into formations is enabled by three features. First, it transmits at a low frequency. Second, it increases the ability to adjust depth of investigation between the transmitter and receivers. Third, it applies a novel mathematical inversion methodology to multiple, deep, azimuthal resistivity measurements in real time, allowing detection of multiple layers around the wellbore.

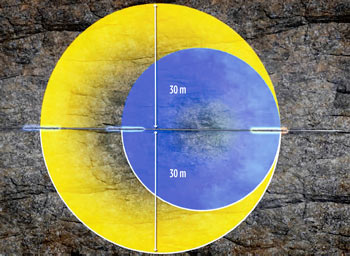

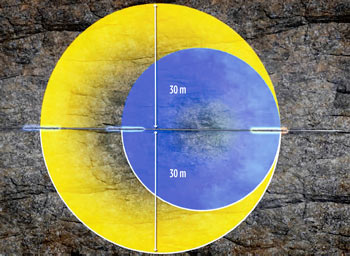

The transmitter is placed close to the drill bit on the bottomhole assembly (BHA), sending multi-frequency electromagnetic signals into the formation at frequencies as much as 50 times lower than legacy technology. Two receiver subs, with more directional antennas than previous tools, are placed on the BHA behind the transmitter at distances up to 30 m, depending on the thickness of the reservoir and the operator’s specific drilling objectives, Fig. 1. Increasing the spacing increases the tool’s DOI. Each antenna receives deep electromagnetic signals from the formation, providing a unique set of azimuthal resistivity measurements at multiple depths of investigation while drilling. Readings are sent to the surface in real time through the measurement-while-drilling (MWD) tool, and fed into an advanced stochastic inversion algorithm. This proprietary inversion technique automatically compares real-time measurements with hundreds of thousands of mathematical models. When it finds a match, the inversion generates an interpretation, incrementally displaying a color-coded resistivity map of the reservoir along the well trajectory in real time.

|

| Fig. 1. The GeoSphere reservoir mapping-while-drilling service reveals subsurface boundaries and fluid contacts up to 100 ft (30 m) from the wellbore, based on the spacing between the transmitter (right) and two receiver subs (left of center). |

|

Deep directional electromagnetic measurements now provide operators a full reservoir-scale view of subsurface boundaries, internal layers and fluid contacts. As a result, drilling engineers and geoscientists can land wells more accurately in the target interval. They also can anticipate changes in structure, ahead of the bit, and proactively adjust the well path to stay in the sweet spot and maximize net pay. The large volume of investigation means wells are steered proactively, rather than reacting to formation changes already drilled, and the resulting well path is much less tortuous than would otherwise have been possible. After drilling, enhanced subsurface characterization data help oil and gas operators refine seismic interpretations, geological reservoir models and future field development plans.

To ensure the success of its Nini East horizontal drilling campaign, DONG E&P decided to integrate real-time, deep, directional resistivity inversions with surface 3D seismic data and formation evaluation measurements while drilling. The BHA consisted of the new reservoir mapping-while-drilling service, a multi-function formation evaluation tool, and a point-the-bit rotary steerable system to enable rapid geosteering decisions, well ahead of approaching changes in structural dip.

When surface seismic data are converted from time to depth, subsurface features and reservoir boundaries often exhibit vertical and/or lateral uncertainties, ranging from a few meters up to tens of meters. Thus, while seismic data provide critical information away from the borehole, they are less reliable for steering in thin reservoirs like the Kolga sand. LWD measurements complement seismic interpretations in two important ways. They provide much-higher-resolution data around to the wellbore, and the accuracy of their depth measurements is very high. The new, deep electromagnetic inversions proved especially useful in overcoming seismic uncertainties in this field, because they could map the reservoir at a depth of investigation similar to the resolution of the reprocessed seismic.

During drilling, therefore, resistivity boundaries were mapped, inverted and visually displayed along the seismic acoustic impedance section in real time. While the seismic data predicted structural changes in the overall geometry of the reservoir farther ahead of the bit, high-frequency deep resistivity values computed by inversion provided continuous real-time quality control of the seismic interpretation while drilling.

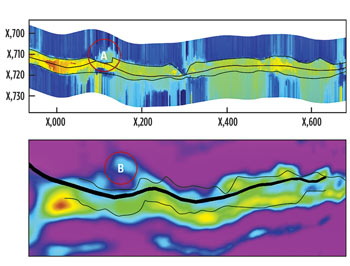

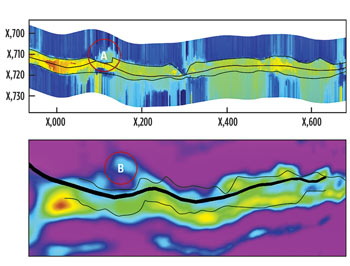

Doubling reservoir exposure and production. The first horizontal producing well drilled by DONG E&P, using the new reservoir mapping-while-drilling service, had a hole size of 8½ by 9½ in. and a planned length of 750 m. Shortly after landing the well in the Kolga reservoir, a confident tie was made near 3,000 m, MD, between the 3D seismic and the deep electromagnetic inversion, based on correlation of a sand injection wing observed in both data sets, Fig. 2. As it turned out, the seismic interpretation was off laterally by approximately 40 m. In addition, the reservoir top was deeper than expected.

|

| Fig. 2. Shortly after landing the first lateral, real-time deep resistivity inversions (top) were tied to the seismic section (bottom), based on an injection wing seen in both data sets (circled). Note: the seismic interpretation was off laterally by about 40 m. |

|

To maintain a safe distance from the overlying Sele shale, which was dipping downward, the drilling team decided to lower the next drilling target and altered the trajectory inclination downward to reach it. Without making that change, the wellbore probably would have exited the reservoir, increasing the risk of not achieving the full length of the planned lateral or requiring a sidetrack. The well trajectory was updated numerous times throughout reservoir steering operations, based on the integration of seismic with deep resistivity inversions.

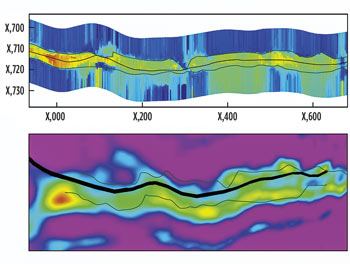

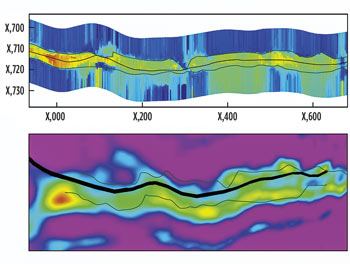

Although the top of the Kolga reservoir was as complex as expected, the reservoir mapping-while-drilling service clearly imaged it, along with most of the reservoir base, even though the resistivity contrast there was quite low. This first lateral achieved a remarkable 98% net-to-gross ratio. It fell short of 100%, mainly because the entire reservoir abruptly disappeared, due to sand remobilization for about 10 m, MD, near the 3,550-m mark, before reappearing again, Fig. 3. The lateral was drilled efficiently in a single run at twice the standard rate of penetration for Nini field, exceeding the planned length by 65 m.

|

| Fig. 3. Complete reservoir section of the first horizontal well, showing boundaries interpreted on the deep inversion. Geosteering achieved 815 m, MD, in the Kolga sand, with a net-to-gross ratio of 98%. Note how the reservoir disappears briefly near the toe of the well (top right). |

|

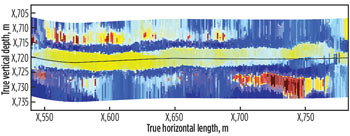

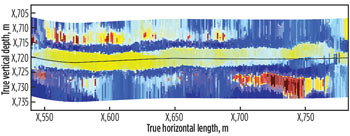

The second horizontal production well had a hole size of 8 in. and a planned length of only 260 m, in order to stop drilling before reaching the OWC. The thickness of the Kolga sand in this area averaged 7 m, and never exceeded 10 m. The resistivity of the reservoir turned out to be slightly higher than expected. Thus, the GeoSphere service clearly defined both the top and bottom boundaries along the entire section, and drillers were able to carry out reservoir steering with confidence, Fig. 4. Near the toe of the lateral, around 2,750 m, MD, the base of the reservoir dropped off on the real-time directional electromagnetic inversions, as predicted, indicating the wellbore was dipping toward the water zone. Drilling was halted immediately. The operator observed that conventional LWD logs, alone, would not have enabled such a timely drilling decision. Again, the entire well was drilled in one run, achieving a 96% net-to-gross ratio in the thin Kolga sand for the full planned length of 260 m.

|

| Fig. 4. Real-time reservoir section of the second horizontal well in Nini East field, clearly showing the top and bottom of the reservoir. Note the drop-off at far right, indicating the wellbore was approaching the oil-water contact, as expected. |

|

In these two new horizontal wells, DONG E&P improved the previous net pay ratio from less than 50% to an average 97%—essentially doubling reservoir exposure and production in each well. There were no sidetracks or delays, and both wells were completed within budget. The wells tested at more than 8,000 bopd, with minimum drawdown.

Deep directional resistivity inversions significantly improved the operator’s understanding of the structure and heterogeneity of this complex, sand injectite reservoir. Detailed information obtained while drilling helped refine the existing reservoir model, reduce uncertainties, and improve long-term field management. Based on this technical and commercial success, DONG E&P plans to deploy the same technology for its next North Sea drilling campaign in early 2015.

Applications and benefits. Since field testing began several years ago, the new reservoir mapping-while-drilling service has been run in more than 180 wells in the North Sea, Europe, Russia, North America, South America, Australia and the Middle East. It was officially commercialized in May 2014. Three primary applications, today, include landing wells more precisely, reservoir steering more proactively and enhancing field development plans. Key benefits include increasing potential production and ultimate recovery, unlocking access to new or marginal reserves, minimizing water production, avoiding drilling hazards, improving the accuracy of reserve estimates, eliminating geological sidetracks and refining seismic interpretations.

Because the deep-reservoir mapping-while-drilling service is capable of interpreting multiple surfaces up to 30 m away, it can also eliminate or reduce the number of pilot holes required to plan horizontal well campaigns. During the past year, for example, another operator in the North Sea used the new reservoir mapping-while-drilling service to map the top and bottom of a target reservoir and gently guide the bit into the ideal landing position without ever drilling a pilot hole. Normally it took about five days to drill pilot holes at rig spread rates around $1 million per day. This is just one of many emerging applications of this new breakthrough technology.

ACKNOWLEDGEMENT

This article is based primarily on SPE paper 159132, “Geosteering the impossible well: A success story from the North Sea,” by Thomas Stærmose, Estela Vazquez Esmerode and Peter Sommer Linnet, DONG E&P; and Soazig Leveque, Christophe Dupuis, and Graham Raeper, Schlumberger. It was presented at the SPE Annual Technical Conference & Exhibition held in San Antonio, Texas, Oct. 8-10, 2012.

|