What's new in exploration

Doing less of what you previously did only makes certain that you will have less of what you had, emphasis on what was once in your bank. I give three examples of creative thinking for going forward. Merry Christmas.

Example 1. One man’s downturn is another man’s opportunity. One company that did well at the 2015 Annual SEG Convention is dGB, selling OpendTect seismic interpretation software. Or should I say giving away basic software with at least the next software level (“Pro”) above that being affordable. Pro is a little less per year than one month’s (U.S.) Social Security check, and can import data from Petrel.

The “new” market consists of all the newly made consultants, who find themselves without the security blanket of Big Oil, and the professional consultants who think SMT-Kingdom (IHS) has traveled the road of Landmark to huge costs. Instead of a $100,000 SMT platform, or the mid-1990s $300,000 Landmark system, a smart-phone-capable exploration geo can use dGB freeware for about 70% of what he or she needs, pay $2,000/year for more analytical tools, and can rent or buy plug-ins for the rest, say for reservoir evaluation.

Plug-ins are created by real users, who see economic value by helping this crowd. What does this paradigm mean? Sophisticated software is now very portable and will be going door-to-door with the professional.

Example 2. I quote Dr. Leon Thomsen of Delta Geophysics, (retired from BP and a professor of geophysics at University of Houston) from a recent RPSEA survey: “The MOST pressing issue for onshore development is … the need to develop a viable strategy for exploration, for the sweet spots of shale productivity. The current strategy has no exploration in it at all; it is—drill in a pattern (e.g. ½-mi grid), and frac. The result is that 80% of the production comes from 20% of the wells (or frac stages). Such inefficiency in field operations would not be tolerated in conventional plays.”

One of our members has drilled over 3,000 horizontals into shale and fraced them all. The firm’s guess is that only about 10% of the fracs produce. Again, Leon explains, “The reason that we don't actually explore for the sweet spots is that we don't know how to. Most of the tremendous advances in exploration over the past 50 years have solved the problem of geophysical imaging through complex overburden, but the shale resource does not usually have complex overburden, so those advances are useless. What is needed is advanced subsurface characterization (based mostly on seismic data, and advanced rock physics). RPSEA should provide leadership to learn how to do this.” Doc, we are trying to do this with several projects, past and present, but our future 999 funding was cut by now-House Speaker Paul Ryan and the 2014 Congress.

Example 3. RPSEA does want to share a research concept that we have been working on, which could be a game-changer in many ways for the fracing sector. At OTC in 2014, two of the RPSEA members exhibited research projects in our booth. One was on fiber-optic VSP, and another was on a chemical seafloor sampler. The chemistry “professor” also had a micro-plastic proppant invention. During discussion, it was revealed that the micro-proppant also collapsed at a specific pressure, making a small noise. That noise was not detectable with existing geophone technology.

Earlier in 2014, field tests of a RPSEA VSP sensor showed x,y,z resolution at 1,500 Hz, and the ability to see motion across or near the surface of the test well pad, in addition to subsurface resolution of under 0.5 m. By August, a proposal was made to DOE, and was funded later for $4 million, with the participation of SWN, RPSEA, Fluidion, NETL and Paulsson, Inc. The project: Inject the micro poppers as a source, along with ordinary proppant, into a frac and see which frac’s worked, in x,y and z, near real time!

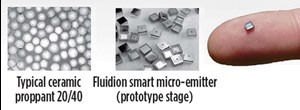

Only a few of the microseismic emitters existed at this point, Fig. 1. Most were tested in a lab, in California, last December. Results were stunning. The fiber-optic VSP sensor could see, in the lab, frequencies over 6,000 Hz, and amplitudes of less than -4 Richter! The micro-source overdrove the sensor. We separated source and receiver some more, de-amped the sensor a bit, and could measure peak energy. Fluidion went back to the design and made chips at different sizes, some to travel short distances, some longer.

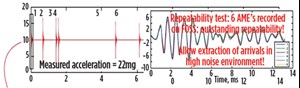

We learned that each had a specific signature and that the sensor tool (Fig. 2) could differentiate amp and frequency to a point, where we could at least calculate the difference among rock types, and water, gas and oil. Vertical resolution was estimated in normal sandstone rock at less than 1 ft. This means that current color interpretation screens on a workstation are seriously dumb to the bandwidth that this tool can produce. A 4,000-dpi UHD monitor, using more than 256 colors, would be better.

Early results were presented at the RPSEA UDW Annual Conference in Septembr 2015. The paper is restricted to attendees for at least a year. A description of the VSP tool is available at, http://www.sciencedirect.com/science/article/pii/S1876610214022838, and at RPSEA and NETL websites. ![]()

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)