As the global demand for energy continues to grow, operators are faced with accessing reserves that, until recently, were classed as uneconomical or operationally risky. Much of this risk stems from the fact that many of these reserves are in remote reservoirs with exceedingly high temperatures and pressures.

However, with continued advancements in technology, and a better understanding of extreme well conditions, operators are more willing to take on ultra-high-pressure/high-temperature (U-HPHT) projects. A Gulf of Mexico operator, for example, expressed such a willingness to extend the industry’s technical limits when drilling a well with a measured depth (MD) in excess of 29,000 ft. Downhole temperature and pressure were expected to reach up to 470°F and 35,000 psi, including the applied pressure required to fire a perforating system.

This article reviews the detailed process that the operator undertook with Baker Hughes to develop and deliver a tubing-conveyed perforating (TCP) system that could successfully deploy in this U-HPHT environment. This would not only enable access to a previously untapped reservoir, but it would mark the first-ever perforation operation at 34,500 psi.

SYSTEM REQUIREMENTS

Perforating guns, which contain multiple explosive charges that create holes in the casing string to allow communication between the formation and the wellbore, vary in diameter and length, but they typically share several main components in common, Fig.1:

- A steel strip to hold shaped charges in place

- A detonating cord that connects to the back of each shaped charge

- Boosters, crimped to each end of the detonating cord

- A hollow carrier into which the assembly fits

- A connecting sub (tandem).

The gun system for any U-HPHT project must withstand not only ambient downhole pressures, but it must also hold up to any additional applied pressure required to operate the firing system. The operator and service provider worked closely to develop design criteria for each component of the perforating system, such that it would work reliably, and safely, with the extreme downhole conditions expected.

Steel. While the past few years have seen considerable improvements in the performance capabilities of high-strength, low-alloy steel, the conditions expected in the Gulf of Mexico well required a higher level of scrutiny in steel quality during the manufacturing process. Any detected anomaly in the material specification must be identified as early as possible, so that corrective action can be implemented and, if necessary, another run of the material can be produced.

Gun system. While selecting a gun system for any U-HPHT project, considerations must be made for the pressure rating and for gun reaction after detonation. Initial calculations were based on the formulas provided by API for the collapse of tubing (API Bulletin 5C3), as well as supplemental proprietary formulas developed for the scalloped gun body geometry. Finite-element analysis showed that the raw material for the guns must have increased minimum yield strength over standard gun body material, to withstand an environment of 35,000 psi and 470°F. The U-HPHT gun system must also include a tandem sub connector that contains an internal fluid bypass, enabling the gun system to be fully compatible with automatic-release systems, and other devices that function by way of gun gas.

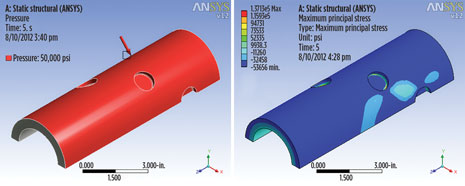

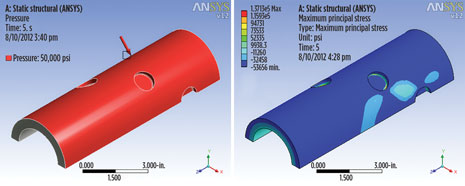

With the initial system requirements in place, Baker Hughes performed a series of simulation models to verify the product’s initial design. The system was designed to exceed the 35,000-psi operational pressure with a safety factor, Fig. 2.

|

| Fig. 2. Applied pressure was 50,000 psi, with a maximum principal stress of 137,130 psi. |

|

No operational problems were observed during the modeling of the proposed equipment layout. However, the up-front modeling, alone, was not considered sufficient for qualifying the TCP system under real-world conditions. The operator and service provider, therefore, collaborated on a suite of real-life, full-scale qualifying tests for both individual components and the TCP system, as a whole.

Firing system. To reduce the risks of operational downtime, it was determined that a redundant firing system would be deployed. Because the firing system had to be fully redundant, the service provider and operator decided on two absolute pressure-activated firing heads that would be conveyed in a shroud assembly. The firing heads used rupture discs with a higher level of accuracy than the shear pin firing heads more commonly used in the industry, which is critical in ultra-deep, high-pressure wells to reduce the amount of pressure required for application. This firing head arrangement still provided a “last-on, first-off,” top mounting arrangement, for further operational safety.

Although they are run in parallel, the firing heads are fully independent of each other, with the explosives train coming together through a device that has two ballistic inputs and one ballistic output. Furthermore, as one of the explosives trains would always reach the TCP device first, or if one of the explosives trains failed to initiate, the device would still initiate the gun string below. This serves to back-detonate the other explosives train, to ensure that the firing head is not pulled out of the hole with live explosives.

Explosives. The project’s high-temperature requirement made hexanitrostilbene (HNS) the best choice for explosive. Exposures to high temperatures for more than the rated duration can cause the explosives to decompose, thus reducing the performance of the shaped charges and leading to a stop fire along the explosive train. Depending on the rate of heating, deflagration—a subsonic combustion process that propagates through heat transfer—is also possible. Deflagration can cause explosives to gas out and build enough pressure inside the gun body to rupture it.

QUALIFYING QUALITY

Because quality is one of the operator’s fundamental business goals, it was of the utmost importance that testing be conducted to the highest standard. As a result, the operator was fully involved in the content of the quality plan for developing and delivering a U-HPHT TCP system that would reliably function in the extreme reservoir conditions expected. The service company’s quality assurance manager was responsible for writing the quality plan. This manager was also integrated fully with the ballistics-engineering group, and had direct access to the TCP product line team.

The project-specific quality plan focused on critical testing for hardware, third-party components and shaped charges. Scrutiny, over and above a standard quality plan, included increased third-party witness and inspection participation, and quality control inspection rates of subcomponents and documentation.

For hardware, this included:

- Lot acceptance testing of raw materials

- 100% inspection of items deemed critical to the success

- Increased levels of non-destructive testing.

The aspects for ballistic devices and shaped charges included:

- Batch qualification testing at well conditions

- Increased levels of non-destructive testing.

Inspection was a critical part of the quality plan, and as such, operator representatives were allowed to freely observe manufacturing and testing activities, per the following guidelines:

- A Monitor Point is an optional inspection point, during which an operator representative, without notice and without constraining the activity, may monitor any applicable activity.

- A Witness Point is also an optional inspection point, in which the service company notifies the operator representative. If available, the representative may witness the inspection point, without constraining the activity. The company or subcontractor’s work will not be held or repeated.

- A Hold Point is a mandatory customer inspection point. The service provider will notify the operator representative when any hold point is reached, and work will not proceed until the applicable inspection activity has been completed, or a written waiver is received from the operator.

Gun body qualification. The steel comprising the gun body was tested during the manufacturing process, once the service company and the steel vendor defined the correct chemistry. The mill run material was then tested by multiple third-party labs and was ultimately accepted, only after the service company, operator and steel vendor confirmed that the material met the requirements.

Complete first-article gun bodies were then machined and pressure tested for qualification. The gun body was sealed with bull plugs on both ends and placed inside a pressure vessel. Pressure and temperature were then increased to 35,000 psi at 470°F and held for 4 hr. No signs of leakage, plastic deformation or collapse were noted on the gun body after the test.

Gun body ballistic qualification. To qualify the gun body for ballistic survival, the 7-ft gun body was fully loaded with selected, HNS, hard rock shaped charges, and shot wet under ambient pressure and temperature. The maximum diametrical swell was 3.544 in., or 1.52% of original OD, which is well below the customer’s specified drift diameter of 3.625 in. The gun body was also drifted, using a 3.625-in. ID drift gauge (18 in. long) after the test and without any issues. No visible splits or cracks were noted on the gun body, Fig. 3. The 3.500-in. OD HPHT gun body was, thus, qualified for survival in wet application using the selected HNS shaped charges.

|

| Fig. 3. Gun tube, fully loaded with the selected shaped charges (left), and the condition of the gun body after the ballistic survival test (right). The gun body did not crack or split during the ballistics test. |

|

EXPLOSIVES QUALIFICATION

Due to the job’s high-temperature requirements, all explosives were batch-qualified for use at 470°F. The explosive powder was also ampule-tested, which was considered the thermal stability test that most closely mimics the conditions to which explosives are exposed in oilfield operations. In this test, a sample of the explosive is sealed in a glass ampule and then placed in a heating block, Fig. 4. The block was ramped up to the desired temperature of 470°F over a 2-hr period, and the block containing the ampules was then held at that temperature for an additional 2 hr. The results of these tests gave a time-versus-temperature chart, based on the specific batch of HNS explosives, which would, in turn, be used on the planned project.

|

| Fig. 4. Glass ampules containing the powdered explosive (left) were placed in a heating block ramped-up to 470°F, and held at that temperature for 2 hr. |

|

Shot tests were also conducted with shaped charges held at ambient temperature, and at reservoir temperature for a period of 2 hr. Shots were made, each at temperature and ambient, to gather sufficient data to make a comparison. The shaped charges were shot into API-specified QC concrete targets, and performance was measured on the basis of the size of the exit holes on the scallops, casing and penetration in the target. The results of this testing confirmed that the explosives in the shaped charge did not decompose or deflagrate, and the drop in performance was negligible in relation to the exit holes and marginal from the target penetration. This marginal drop in performance was deemed acceptable, and all shaped charges were qualified for use at 470°F for the expected duration.

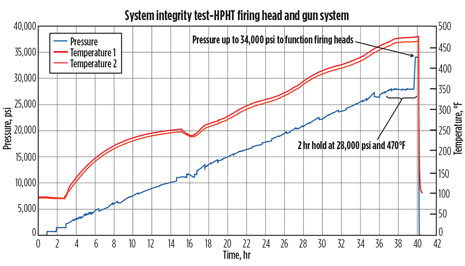

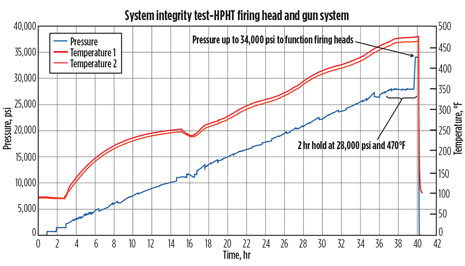

System integrity test (SIT). A final test was performed to qualify the system for use, as per the customer-specified well conditions, which consisted of the U-HPHT firing head system connected to two 1-ft gun bodies and a tandem sub, with detonation cord and booster-to-booster transfer. All items used in the test were from the same batches that were previously qualified for use in the well. The purpose of the test was to validate the successful ballistic train activation of the firing heads, and the detonating cord booster-to-booster transfer at these elevated temperatures and pressures.

|

| Fig. 5. Time–temperature data for the duration of the test. |

|

The entire assembly was lowered into the pressure vessel, which was then sealed and brought to temperature and pressure under controlled conditions meant to simulate running in hole. Temperature was increased in a linear ramp from 72°F to 470°F (approximately 11°F every hour), while pressure was increased from 0 to 28,000 psi, over a period of 38 hr. This length of time approximated the time that it would take to get the assembly to target depth in the well.

The tool was then soaked at 28,000 psi and 470° F for 2 hr, followed by increasing the pressure to activate the time-delayed firing system. A loud mechanical noise of the hammer sub shifting at 32,400 psi confirmed the successful rupture of the discs and initiation of the time delay.

Four minutes and 28 sec later, the time delay of the firing head system successfully detonated. A 100-psi increase in pressure inside the vessel—caused by expanding gases released during detonation—confirmed the successful detonation of all explosives. The vessel was depressurized and allowed to cool for the rest of the day. The tool was retrieved from the vessel the next day and carefully disassembled to retrieve the witness plate. The uniform explosive imprints along the plate confirmed a successful test and high-order detonation of all explosives.

TAKING TO THE FIELD

All qualifying tests for the U-HPHT gun system were successful, with full function of the U-HPHT firing head at the desired pressure and temperature. There was high-order detonation of the explosive train following a customer-specified time-temperature ramp-up. Based on all tests and qualifications, the service company’s ballistics engineering group determined that the U-HPHT firing head assembly, and all the components of the U-HPHT gun system, were batch-qualified and suitable for use at 35,000 psi and 470°F for the duration and temperature ramp-up specified in the test.

With these assurances, the operator moved forward with deploying the new TCP in its well. The perforating string included multiple perforating guns with the redundant firing system, as qualified in the described testing. After reaching perforating depth, an absolute bottomhole pressure of 34,500 psi was applied and bled off to activate the time-delayed redundant firing system. With a positive indication of gun detonation, circulation between tubing and annulus was confirmed, and the assembly was pulled from the wellbore. Full gun detonation was confirmed by visual inspection of the spent gun bodies. All perforating charges fired, all ballistic transfers across tandem connections were successful, and all perforation shots hit within scallop.

Without this U-HPHT perforating system, which came from careful planning and close collaboration, the operator would have had to spend months in R&D, potentially costing millions of dollars. Even greater savings were realized through flawless execution at the rig site. Most importantly, the industry’s first U-HPHT perforating system enabled the operator to access a previously inaccessible formation.

A collaborative technology development such as this is a clear example of how the correct team, combined with a understanding of the operator’s requirements, can deliver products that successfully meet new operational challenges.

ACKNOWLEDGEMENT

Parts of this article were adapted from SPE paper 170300.

|