PRAMOD KULKARNI, Editor

Operators seeking to exploit the prolific Lower Tertiary tight sands in the deepwater Gulf of Mexico are facing the same dilemma that George Mitchell encountered, while trying to produce gas from the Barnett shale—low-permeability formations are not able to produce without fracing. While fracing the Barnett shale was tough enough, fracing at Lower Tertiary depth (>40,000 ft) in the Gulf of Mexico under deepwater conditions is fraught with a great number of technical challenges, including HPHT conditions. Among these is the challenge that the operators issued for creating a proppant that has at least twice the conductivity, at 20,000-psi closure stress, compared to conventional high-strength ceramic proppant.

CARBO took up the challenge in 2007. Through six years of intensive research and development, the proppant manufacturer has developed a unique product that meets the operator’s conductivity requirement. Branded KRYPTOSPHERE, the new proppant has high Alumina composition, plus certain additives that CARBO is keeping as secret, as the formula for Coke. CARBO has also devised a proprietary manufacturing process that enables KRYPTOSPHERE to achieve three exceptional properties: ultra-high strength, ultra-spherical shape and ultra-smooth surface.

World Oil received a greater understanding of the KRYPTOSPHERE proppant through an exclusive interview with CARBO executives: Don Conkle, V.P. of Marketing and Sales; and Terry Palisch, Director of Petroleum Engineering.

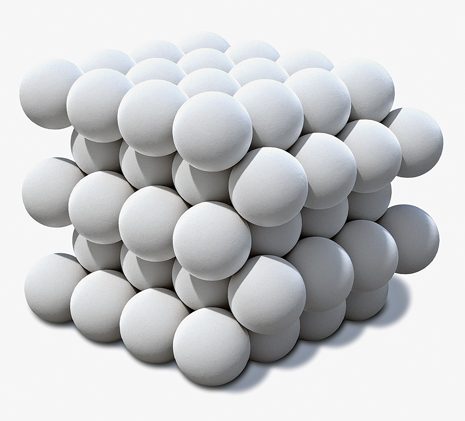

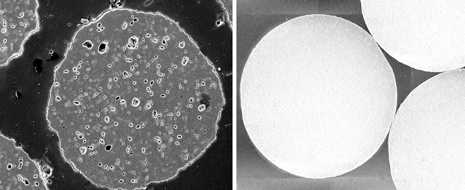

New material, new process. “We first looked into changing just the proppant material, but that wasn’t working. We needed to change both the raw material and the process. It was the marriage of both new materials and new process that enabled us to meet the challenge,” explained Palisch. “If you look at the proppant conductivity pyramid, the base is ordinary sand that has low conductivity. For the next level, you can coat sand with resin and make it more conductive. If you go next to man-made ceramic proppants, you can engineer additional gains in strength and conductivity. Now, KRYPTOSPHERE takes us to the highest level in strength, shape, durability and conductivity,” Fig. 1.

|

| Fig. 1. The KRYPOSHERE proppant has achieved ultra-high strength and the highest available conductivity. |

|

“We could’ve taken conventional materials and used our new process to make a better product. Or, we could’ve taken the new material, but used a conventional process to also make a better product,” said Conkle. “But, the combination of materials and a new process has helped us achieve a step change in performance.”

|

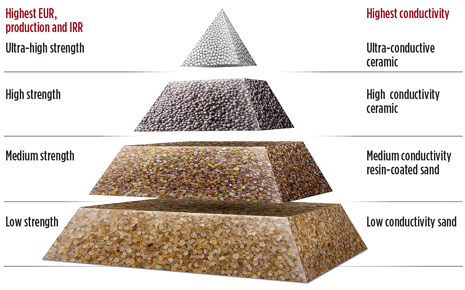

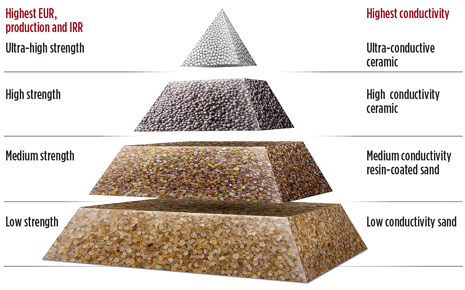

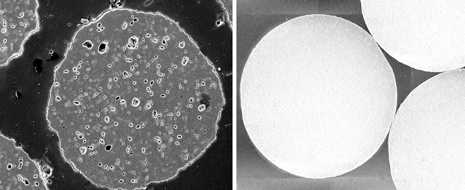

| Fig. 2. Spherical shape of the KRYPTOSPHERE proppant (right) enables greater flow space than high-strength bauxite. |

|

“What we’ve accomplished is the creation of more space,” added Palisch. “Coupled with the high strength, the uniform size of the proppant, the spherical shape, and the very smooth surface allow more hydrocarbons to flow,” continued Palisch. “Consequently, the greater conductivity yields more production and greater EUR. Compared to onshore shale plays, there are even bigger dividends for the Lower Tertiary tight-sand formations,” Fig. 2.

Higher Alumina content. The higher strength is related to the Alumina content of the various classes of proppant products. “If you look at ceramic proppants in general, a lightweight ceramic product is 45%–50% Alumina,” explained Palisch. “An intermediate-density proppant is 70%–75% Alumina. A high-density proppant (bauxite) is 80%–85% Alumina. But KRYPTOSPHERE has very high Alumina, plus proprietary additives. Whereas bauxite is dark-colored because of impurities, such as iron content, high Alumina is actually light-colored. KRYPTOSPHERE actually looks white.”

Uniform size. When you take a proppant, whether it is sand, resin-coated sand or ceramic, you get a range of particle sizes. For example, for 20/40 mesh size, there is some percentage of grains that falls on the 25-, 30- 35- and 40-mesh screens. To qualify as a 20/40 mesh proppant, 90% of the product has to fall between the 20- and 40-mesh screens.

“Our current CARBOHSP (bauxite) has a relatively tight sieve distribution, but with the KRYPTOSPHERE process, we get a single, uniform size,” exalted Palisch. “We can dial-in a precise micron size. Instead of specifying a 25-mesh size, we can actually specify an 810-µ size that is within ±30 µ. We’ll be able to tailor a specific size to the application. This will be important for offshore applications, such as gravel packing.”

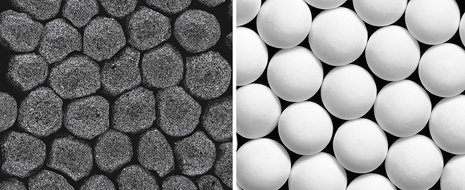

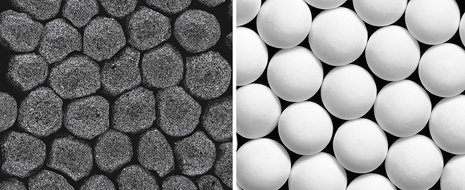

|

| Fig. 3. Lab testing shows the KRYPTOSPHERE proppant achieving twice the baseline conductivity of HSP proppant at 20,000-psi closure stress. The conductivity spread is even greater at higher stress levels. |

|

Conductivity testing. Using standard API/ISO conductivity test procedures, KRYPTOSPHERE was tested against 20/40 CARBOHSP (bauxite) proppant. The lab tests revealed that KRYPTOSPHERE 25-mesh proppant has twice the reference conductivity at 20,000-psi stress, as compared to CARBOHSP. At higher stresses, it appears there is even greater separation between the two conductivity curves, according to Palisch, Fig. 3.

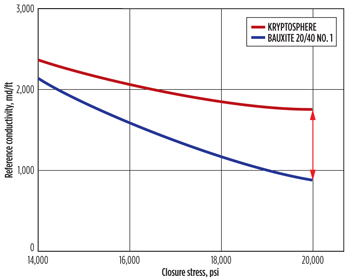

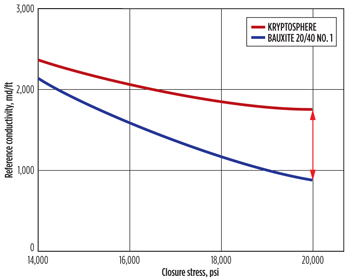

Greater strength. A microscopic view of the cross-sections of various conventional ceramic proppants reveals many, relatively large-sized pore spaces, despite an overall internal porosity of 4–6%. However, a proppant grain is only as strong as its weakest point, which ends up being these large pores. That’s where failures will occur. Through its unique materials and pelletization process, the porosity of KRYPTOSPHERE proppants is typically 1–2%, and these pores are uniformly scattered throughout the grain in very small pores, Fig. 4.

|

| Fig. 4. KRYPOSPHERE proppant’s durability is the result of ultra-low pore space, as compared to high-strength bauxite (left). |

|

Greater durability. The downhole stress levels change, due to workovers and operating conditions during the life of a well. As a result, proppants get rearranged, and the conductivity usually drops. CARBO had an independent lab test the impact of stress cycling on the KRYPTOSPHERE proppant as compared to two standard bauxite proppants. The lab cycled the proppant five times from 20,000 to 12,000-psi stress levels and then remeasured the conductivity at 20,000 psi. The KRYPTOSPHERE proppant measured four times the conductivity, compared to the bauxite proppants.

“The microstructure of the KRYPTOSPHERE yields long-term durability,” Palisch explained. “As a result, an operator can expect to achieve longer production and greater EUR, even after destabilizing events, such as well shut-ins or workovers.

The exceptional durability of the KRYPTOSPHERE proppant also opens up high-temperature steamflood and geothermal applications, according to Palisch, because there is no proppant available on the market that can effectively handle such extreme conditions.

Resistance to erosion. In most Lower Tertiary well designs, the operator is limited by the amount of erosion that the service tool can handle. If there is significant erosion, the service company will experience difficulty in retrieving the tool back to the surface. Service companies typically conduct flow loop testing to determine the amount of proppant that they can circulate past the tool, e.g., 800,000 lb. “So, the operators cannot design the fracs to what the reservoir needs, but on the basis of how much erosion the service tool can handle.”

To determine the effects of erosion caused by the KRYPTOSPHERE proppant as opposed to a HSP proppant, CARBO asked an independent lab to inject both types of proppants past erosion coupons. “Even at low flowrates, the erosion rate of HSP proppant is significantly more than KRYPTOSPHERE,” Palisch revealed. “At high velocities, the difference is dramatic. This tells us that Lower Tertiary operators will be able to design larger frac designs and get more drainage out of the reservoir.

“Angularity of the proppant is the biggest factor in causing erosion,” Conkle added. “The secondary factor is the surface roughness of the angular pellet. With KRYPTOSPHERE, you get an ultra-spherical shape, as well as an ultra-smooth surface.”

Field testing to come. After completing internal testing, CARBO is providing KRYPTOSPHERE samples to E&P companies for their own internal testing and testing at independent labs of their choice. “Most likely, the first deepwater job will take place after Q1 of 2014,” Conkle added.

Fracturing of the Barnett shale opened up onshore tight shale plays throughout North America, and, eventually, the world. The introduction of the KRYPTOSPHERE proppant fits one piece of the puzzle in opening up hydraulic fracturing of tight-sand, and perhaps, shale plays in the extensive deepwater arenas.

|