BRENT BROUGH, Resman

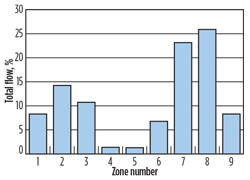

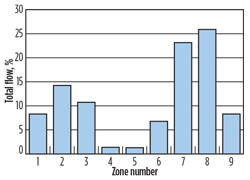

Crude oil producers are responding to the reservoir management challenges of multi-zone horizontal wells with intelligent tracers that quantify inflow distribution on a zone-by-zone basis. The inflow distribution analysis from a recent well, equipped with RESMAN RES-OIL intelligent tracers, shows that about half of the total inflow came from only two segments (7 and 8) of a 9-zone well, Fig. 1. RESMAN data also identified two low-producing zones (4 and 5), accounting for only 3% of total inflow. The operator was expecting a more even inflow distribution, and used this knowledge to reassess the reservoir drainage properties and adjust drilling and completion strategy for future wells in the field.

|

| Fig. 1. Inflow contribution of each zone of the horizontal well. |

|

QUANTITATIVE INFLOW ASSESSMENT

The constant release of tracer chemicals is flow-independent, which can be used for a variety of functions. During steady-state flow, it is used as a diagnostic tool to assess if any zone has stopped producing. During well start-up, it is used to calculate the quantitative inflow distribution of each reservoir segment.

Quantitative inflow distribution is accomplished by the continuous release of tracers during a shut-in period, causing a buildup of concentration in the fluids immediately surrounding the tracer rods, which are located at the zonal-entry points. The well is then restarted, and inflow from the reservoir segments carries the oil with high tracer concentration from the annular area into the main wellbore flow path. The segments with higher inflow rate will displace the annular volume faster than segments with lesser inflow rate. This flow pattern results in tracer concentrations of the high inflow segments declining faster than concentrations from the segments with the lesser inflow rate. The inflow distribution is determined by analyzing the change in tracer concentration in the surface samples that are collected during the well’s start-up after a short shut-in period.

|

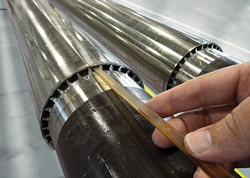

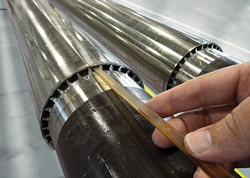

| Fig. 2. Tracer rods being inserted into a screen. Oil from the reservoir contacts the RESMAN tracer rods, which release small amounts of the intelligent tracer. Then, oil travels to the surface through ports in the base pipe. |

|

RESMAN recently completed of a full-scale, flow loop testing program, which demonstrates a precise correlation (within ±5%) between its modeling estimates and actual flow. The tests were performed at the facilities of the IFE research institute in Norway.

WIRELESS, INTERVENTION-LESS RESULTS

The RESMAN system utilizes its proprietary RES-OIL intelligent tracer rods with dozens of different chemical compounds that can be installed easily in screens, in each segment of the horizontal well. The oil produced from each segment will only contact the tracer rods deployed in that segment. At the surface, oil samples are taken and analyzed for the concentration of each of the different chemical compounds. The change in concentration during a start-up of the well can be correlated to the specific flowrate coming from each segment.

The RESMAN systems can provide continuous information for up to five years, depending on downhole temperature and flowrates. No entry into the well is needed to provide assessments of the inflow distribution. Continuous surveillance of the reservoir is accomplished by periodic sampling of the production during the life of the tracer systems. The absence of one of the tracers in the produced fluid provides reliable evidence that a segment has stopped contributing.

DETECTING WATER INFLUX

The RESMAN wireless reservoir management system is also designed to detect water influx. RES-H20 intelligent tracer rods, which contain water-sensitive chemicals, are in each zone for this purpose. When water production begins, the water-sensitive systems will indicate the location of water influx. These data will be used to tune the reservoir simulator and provide additional intelligence for reservoir management decision-making. The RESMAN water-sensitive tracers are dormant until contacted by water. Their life span is one to two years after water breakth©rough.

RELIABLE, QUANTITATIVE RESULTS

The use of RESMAN RES-OIL and RES-H20 intelligent tracers is a reliable, cost-effective means of acquiring quantitative results of inflow distribution in environments, where there are only very expensive, complex and risky alternatives.

|

The author

BRENT BROUGH is the Chief Commercial Officer for RESMAN. Prior to joining RESMAN in 2011, Mr. Brough spent the majority of his career working for Schlumberger in a variety of positions across Russia, the UK, Norway and Canada. |

|