N. Wagner, L. Brantley, C. Grosvenor, F. Florence and J. Ogg

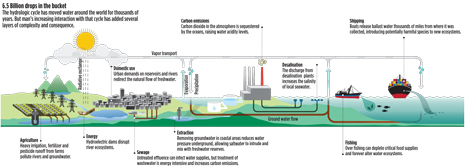

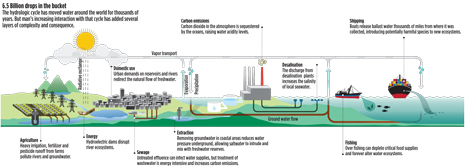

Access to clean water is a global issue requiring local solutions such as collaboration between multinational corporations, the energy industry, and local communities and governments. Worldwide, 884 million people (14% of the world’s population) lack access to clean and safe water.1 According to the United Nations (UN), global trends show that 70% of the world’s water sources are used for agriculture and irrigation and 10% on domestic uses.2 A summary of the hydrologic cycle and the demands general industry practices place on the water supply is available in Fig. 1, with an emphasis on surface water.3 According to the UN, in developing countries, 70% of untreated industrial waste is disposed into water, contaminating existing water supplies.4

|

| Fig. 1. The hydrologic cycle (IBM, 2009) |

|

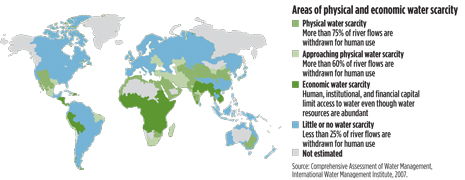

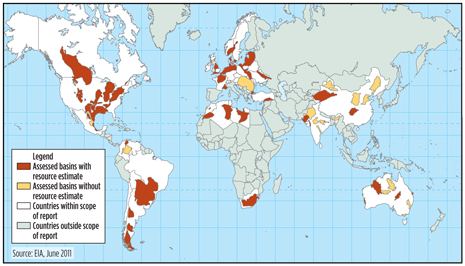

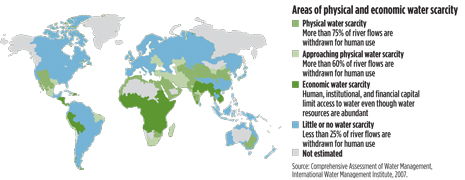

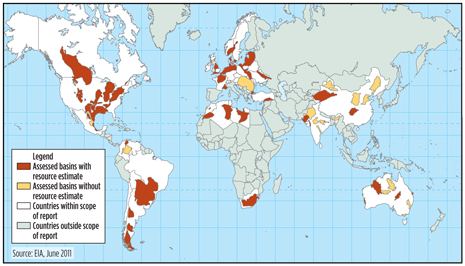

Currently, oilfield-related activities are competing for regional water supplies in certain areas. It is possible for these activities to combine knowledge and technologies to increase clean water access as well as drive economic development.5 The map in Fig. 2 shows areas with water scarcity6 while Fig. 3 reviews areas of potential unconventional development worldwide.7 A comparison of Figs. 2 and 3 shows areas with limited water access that could benefit from drilling infrastructure. In Africa, for example, Algeria, Libya, and South Africa are experiencing or approaching “physical water scarcity” and have potential shale resources. Mexico and the United States are in similar positions. Areas of China show “economic water scarcity” in areas of proven shale reserves. Interestingly, Australia exhibits both available water resources and significant shale reserves. This may have to do with the extensive efforts Australia has taken with recycling produced water. Of the countries where there is clear overlap between water scarcity and active or potential drilling activity, the U.S., Guatemala (listed with water scarcity but not large unconventional reserves), South Africa, China, and Australia will be reviewed in more depth in this paper.

|

| Fig. 2. Map of water scarcity (IWMI, 2007) |

|

|

| Fig. 3. Global map of unconventional reserves (World Shale Gas Analysis, 2011) |

|

DRILLING AND COMPLETION WATER NEEDS

The growth of multi-stage hydraulic fracturing has dramatically increased the oil and gas industry’s water needs. Conventional vertical wells typically use an estimated 0.25 to one million gallons of water per well.8 However, an unconventional well requires the same amount of water to fracture a single stage. Total water needs for an unconventional well are estimated to be three to five million gallons.

The following examples of water usage in unconventional wells (unless noted as conventional) demonstrate the extent to which water needs have increased:

Conventional well: 0.5 to 0.66 million gallons (2000-2500m3) for a 6,000 ft (1800m) well

Average rate of ~100 gallon/ft (1m3/m)

Marcellus well: 4 to 5.6 million gallons (15,500–21,200m3)

Haynesville well:

0.7 million gallons (3,000 m3) for conventional verticals

7 million gallons (26,500 m3) for wells with 10,000 to 13,000 ft (3,000–4,000 m) total depth with 10–15 hydraulic fracturing stages

Average rate of 800–1,000 gallons/ft (3–4 m3/m)

Barnett Shale: 3 to 3.6 million gallons (11,400 to 13,900 m3) (Conti, 2012)

There are four main sources of water for oil and gas drilling and completions needs: 1) groundwater; 2) surface water; 3) municipal or industrial wastewater; and 4) production, flowback, or brackish water. Groundwater represents a large percentage of the world’s total fresh water supply. As such, the industry aims to reduce groundwater usage, as groundwater is currently the most common source of water for drilling and completions.

Water sourcing and management is critical for sustainable unconventional development. As “the largest volume by-product or waste stream associated with oil and gas exploration and production,” produced water may be a valuable resource for meeting growing water needs.9 The industry is already making strides to increasing produced water’s role in their water source portfolios. For example, one operator describes its water management goals for unconventional development in Canada as follows: 1) elimination of potable water usage, 2) reduction of groundwater usage, and 3) identification and use of produced water sources.

Produced water is often a combination of returned fracture fluid and natural formation water. It tends to exhibit the following characteristics:

Salinity from 30,000 to 150,000 ppm (rarely higher)

Iron from 25 to 2,000 ppm

Barium from 0 to >250 ppm

Oil carryover to 300 ppm

Bacteria from <1,000 cells/ml to 109 cells/ml

Total Suspended Solids (TSS) of up to 3 to 5,000 ppm, 1 to ~210 microns (70 mesh)10

Based on recent developments and trials, there are a few reasons why salt water may be a better base fluid for most fracturing operations than originally thought. Part of the hesitation to move toward saline hydraulic fracturing base fluid is that fresh water has always been used until recently. During some of the past non-drought years, the use of fresh water for drilling has flourished due to the ease of garnering a fresh water supply from local landowners in exchange for a price, ease of hauling and limited chemical additive problems. In a drought year, that situation is significantly altered. Salt water offers an attractive solution due to its availability in regions where hydraulic fracturing is practiced (partially from produced water sources). Further, this could reduce air emissions due to less need for hauling/truck transport or by allowing for use of temporary pipelines with pad drilling operations. The industry now sees produced water as a valuable resource, not waste.

As the availability of surface and subsurface water supply options vary from play to play, there is a growing trend to reuse fracture flowback water, making future use of more brackish water from deeper aquifers likely. In addition, mobile water treatment units can be used to recycle water on-site. The treatment and disposal of hydraulic fracturing water varies from 1 USD to 2 USD/bbl for treatment and 2 USD to 2.50 USD/bbl for disposal via deep well injection. As a result, treatment and reuse are becoming more effective choices in some plays for economic, logistical, and public relations reasons. Overall, water reuse and the use of salinity-tolerant hydraulic fracturing fluids is becoming increasingly popular.11

The availability of suitable water for hydraulic fracturing and the means for environmentally responsible water recycling and disposal are critical for sustainable unconventional development. Water management needs vary depending on the location of the shale play. In the population-dense area surrounding the Marcellus, for example, water disposal poses the largest challenge. Produced water that comes to the surface during oil and gas recovery presents a challenge for Marcellus drillers. It “is the largest volume by-product or waste stream associated with oil and gas exploration and production.”9 Often a combination of returned fracture fluid and natural formation water, produced water is generally characterized by a high salinity and total dissolved solids (TDS) and requires proper treatment and disposal. “The cost of managing such a large volume of water is a key consideration to oil and gas producers.” During the second half of 2011 in the Marcellus, over 450 million gallons of water was produced. Sixty-five percent was recycled as hydraulic fracturing water, 26% was treated and discharged to rivers, and 9% transported to Ohio for deep well injection.12

Conversely, in the Eagle Ford, water is typically sourced from aquifers that are also the major water suppliers for municipal, industrial and ranching use. Availability is tight, particularly since South Texas is often plagued by drought. Occasionally, deeper aquifers with brackish water can be sourced for fracturing.12 Recently, both the cities of Corpus Christi and Kingsville proposed with the Texas Commission for Environmental Quality (TCEQ) to market the sale of water to energy companies for hydraulic fracturing. The municipalities look at the sale as a source of revenue, with the potential to offset water rates that are estimated to increase by 17% in the next ten years. One area of contention is that the city is currently asking the residents to curb water use due to a limited supply for drinking water. The other area of contention is that in the event of a drought, the water contracts that might exist with energy companies would become void. Finally, the last area of contention is how to find a beneficial use of the flow-back water generated.13

DRILLING AND COMPLETION IMPROVES WATER ACCESS

This background is setting the stage; the timing and monetary motivation is in place for water re-use. The missing piece is the connection to how oil and gas operations can help with local water needs. With the many millions of gallons of water in question, and often in areas of water constraints, there are many ways to provide a non-potable water source for communities looking at agricultural and sanitary needs. It is likely that waters used in oil and gas operations will need treatment before beneficial use is an option.

Oil and gas development operations are also related to environmental contamination concerns. The recent activities in hydraulic fracturing and related studies undertaken by many groups have not connected groundwater contamination to the practice. However, an area of risk that is still present is posed by spills, and it is important to note that best practices and environmentally responsible approaches are required for all oilfield related activities.14

Drilling and completion operations may be able to improve local communities’ water access. A possible approach would be a collaborative partnership between the energy industry, municipal and federal governments, and local stakeholders to source and categorize water sources. Using this approach requires that the industry’s operational needs be openly related to the community and vice versa. In this way, water infrastructure can be designed with the needs of all stakeholders in mind. In considering water-related interactions between operators and local communities, we will review both domestic and international communities. The examples described below are projects that have successfully engaged community needs with oil and gas operations in the U.S., South America and Australia.

Kern County, California, USA. Domestically, farming and irrigation may be the best examples. One example can be found in Kern County, where an operator has its largest California oil field using steamflooding technology to extract oil from the ground. The process generates ten barrels of water for every one barrel of oil, so the company has partnered with the Cawelo Water District to redirect produced water for agricultural use. The same operator also worked with two municipal water treatment plants near a Richmond facility to repurpose ponds formerly used by a chemical company. The ponds now provide additional storm water surge capacity, to help prevent sewage and untreated wastewater from bypassing the system and flowing into San Francisco Bay during big storms.15

According to the operator, it strives to consult the list below in their decisions with respect to fresh water:

Continually reduce environmental impact of operations.

Integrate fresh water conservation and efficiency drivers into our business decision-making processes and operational management.

Conserve fresh water in fresh water-constrained areas by reusing, reducing, and/or recycling water.

Account for use of fresh water in operations, with appropriate metrics.

Engage with governments, partners, local communities and other stakeholders on fresh water resource issues in areas where we operate.

Build partnerships and participate in industry initiatives to share and promote best practices, assist with the development of industry standards, and shape and influence relevant fresh water resource policy.16

This transferring of water and extension of the beneficial life cycle of the resource has received a number of positive reviews from the surrounding community. As a result, many economic opportunities and livelihoods are benefiting from an expanded view to oil and gas operations.

Guatemala and South America. Internationally there are many examples of operators working with communities to manage water resources. One project, conducted in the Rubelsanto area of northern Guatemala several years ago showed that it can be done at little cost but with huge benefits. As mentioned above, a review of Figs. 2 and 3 shows Guatemala having water scarcity but not large unconventional reserves. This case study is in relation to the development of conventional oil and gas resources.

The drilling site was located a few kilometers due north of a water source (local river), and the main road ran parallel to the river. An auxiliary road crossed the river east of the rig location. A local village was situated just to the south of the intersection of the main and auxiliary roads. The contractor had a choice: run a short water line through the jungle, from the river, directly to the rig site, or make a longer run by laying the line alongside the roads. The contractor chose to take the longer path and a water line was constructed from the river, running north alongside the auxiliary road, and west along the main road, passing through the village and continuing to the rig site. A small spigot was placed on the line in the middle of the village. This provided a water supply to the villagers who normally carried water by hand from the river.

In addition, when rig personnel were traveling in the area, the contractor routinely allowed the local farmers to ride in the bed of their trucks, taking them to and from the fields west of the village. The fields were in between the rig site and the village along the main road. On one occasion, a woman ran from a small house in the village carrying a baby, who had turned blue. The rig hands performed mouth to mouth resuscitation and drove the mother and infant to a clinic about 35 km from the village.

A few weeks into the drilling campaign, guerrillas entered the village one night and demanded food and a place to stay, stating that they were going to the oil rig the next day to shut down the operation. In years past, they had forced crews from the rig camp at gun point and tossed hand grenades into the facility. The villagers local community gave testament to the fact that the rig crews provided the community with water, they often drove them to and from work, and they saved one of the local children in an emergency. The public outcry convinced the guerrillas not to attack the rig or harm to their personnel.

Thus, the contractor, by simply doing the right thing, though it required more pipe and labor in terms of the water line, acted as a good neighbor. Unbeknownst to them at the time, this simple act would later lead to uninterrupted operations without damage to their rig.

Coming next month: The second and final part of this article will examine additional examples outside the U.S., where community needs have successfully engaged with oil and gas operations.

REFERENCES

1 WHO/UNICEF. (2010). Progress on Sanitation and Drinking Water 2010. Retrieved May 2012, from Joint Monitoring Programme for Water Supply and Sanitation: www.wssinfo.org

2 AQUASTAT. (2012). “Water Use”. Retrieved May 2012, from Food and Agriculture Organization of the United Nations.: http://www.fao.org/nr/water/aquastat/water_use/index.stm

3 IBM. (2009). Water–A Global Innovation Outlook Report. Retrieved July 2011, from IBM: http://www.ibm.com/ibm/gio/media/pdf/ibm_gio_water_report.pdf

4 Water, U. (2010). World Water Day 2010–Facts. Retrieved June 2012, from UN Water: http://www.unwater.org/wwd10/downloads/WWD2010_Facts_web.pdf

5 Exxon Mobil. (2010). Corporate Citizen’s Report. Retrieved 2011, from Exxon Mobil: http://www.exxonmobil.com/Corporate/community_ccr.aspx

6 IWMI. (2007). Comprehensive Assessment of Water Management. Retrieved 2011, from International Water Management Institute:: http://www.iwmi.cgiar.org/assessment/files_new/synthesis/Summary_SynthesisBook.pdf

7 EIA. (2011, April). World Shale Gas Analysis. (US Department of Energy) Retrieved 2012, from Energy International Association: http://www.eia.gov/analysis/studies/worldshalegas/pdf/fullreport.pdf

8 Yost, A. (2011). Water Management During Shale Gas Development: Current R&D Efforts. In N. E. Laboratory (Ed.), Developing Unconventional Gas. San Antonio.

9 Laboratory, A. N. (2009, September). Produced Water Volume Report. Retrieved June 2012, from Argonne National Laboratory: http://www.evs.anl.gov/pub/doc/anl_evs__r09_produced_water_volume_report_2437.pdf

10 King, G. E. (2011). Alternate Water Sources for Fracturing. Developing Unconventional Gas. San Antonio.

11 Dale Pierce, N. F. (2012, June). Drilling and Completion Water Needs. (N. M. Lydia Brantley, Interviewer)

12 Burris, K. (2011). Water Management for Nonconventional Gas: Eagle Ford Shale Play. In W. Parsons (Ed.), Shale Gas & Tight Oil Argentina. Buenos Aires.

13 Savage, J. (2012, June 27). Corpus Christi to request permit so it can sell raw water to companies involved in Eagle Ford Shale. Corpus Christi Caller. Retrieved July 9, 2012, from http://www.caller.com/news/2012/jun/27/corpus-christi-to-request-permit-so-it-can-sell/?partner=RSS

14 Harold D. Brandon, D. J. (2011). Progression Toward Implementation of Environmentally Responsible Fracturing Processes. SPE Annual Technical Conference and Exhibition. Denver: SPE.

15 Chevron. (2012, April). Environment. Retrieved June 2012, from Global Issues: http://www.chevron.com/globalissues/environment/

16 Chevron. (2012, April). Fresh Water Position Statement. Retrieved June 2012, from Chevron: Global Issues: http://www.chevron.com/globalissues/environment/freshwater

|

The author

NATALIE WAGNER received a BS degree in engineering from the Colorado School of Mines in 2008. Natalie has authored numerous SPE/IADC papers, and was corporate environmental risk manager at National Oilwell Varco from 2008 to 2011. Natalie is currently an environmental engineer with Cross Divisional Environmental Solutions.

LYDIA BRANTLEY holds a BA degree in International Relations and Spanish from the University of Southern California. She began with NOV in 2010 as a member of its Next Generation program and now works in Investor Relations.

COURTNEY GROSVENOR received a BS degree in mechanical engineering from the University of Texas at Austin in 2011. She has co-authored multiple ASME and SPE papers on energy technology and drilling operations. Courtney is an implementation engineer within the Corporate Process Development group at NOV. Courtney will begin graduate studies at the University of Michigan in fall 2013.

FRED FLORENCE received his BS degree in electrical engineering from Southern Methodist University, as well as an MA in international management and an MBA in marketing from the University of Texas at Dallas. He joined NOV in 1996 and has held engineering, project management and operational positions. He is a former chairman of the SPE Drilling Systems Automation Technical Section (DSATS) and has authored numerous SPE papers.

JEREMY OGG graduated from Texas A&M University in 2005 and joined Diamond Offshore working as a roustabout, ballast control operator and roughneck. He then joined National Oilwell Varco’s Next Generation Program in 2007, and upon completion moved to Singapore as the first international on-site solutions director. In 2011, Jeremy moved to Norway to work in the Kristiansand project sales team, focusing on Well Intervention Vessels and Operators. Jeremy is currently manager of strategic sales support and marketing for the rig solutions offshore group at NOV.

|

|