What’s new in well logging and formation evaluation

Part 1, Logging: General developments include ongoing efforts to improve the accuracy of wellbore surveys. New LWD developments include cement evaluation; azimuthal acoustic tool and LWD NMR, among others. New wireline developments include openhole acoustic single-well imaging, borehole radar, geomechanics, pulsed-neutron geochemical logging, wireline formation testing and reservoir connectivity evaluation, among others.

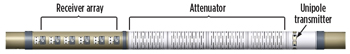

STEPHEN PRENSKY, Consultant, Silver Spring, MarylandWELLBORE SURVEY ACCURACY Recent developments in logging and formation reflect the continuing high priority assigned to exploration and development of unconventional resources. Many new developments are related to achieving greater accuracy in drilling and landing (geosteering) horizontal wells in the development of tight gas, shale, heavy oil, and coalbed methane (CBM) resources. Accurate well surveys are central to achieving geosteering. Low-permeability reservoirs require large numbers of wells to achieve economic success. As the use of multi-well drill pads becomes more common, the potential for well collisions is a serious concern. An SPE workshop in September 2012 summarized the state of wellbore surveying; managing collision risks; planning and drilling relief wells; and practical recommendations for improving survey accuracy.1 Improving survey accuracy, especially in northern latitudes, has been the subject of ongoing, joint research efforts between Baker Hughes and several Norwegian universities.2,3 The magnetic properties of the drilling fluid can be a major source of error in determining wellbore azimuth in deviated wells, especially in Arctic regions. Many drilling fluid additives, such as bentonite clay, shield the earth’s magnetic field that is measured by MWD sensors. The magnetic shielding effect, which is a function of the fluid’s magnetic susceptibility, can routinely result in azimuth errors of 1° to 2°—under unfavorable conditions, this error can increase five- to ten-fold.3 The Drilling Engineering Association, an industry forum, has completed project DEA-164, developing “Next generation directional MWD tool requirements for improving safety and accuracy.”4 A final report on this project, sponsored by Baker Hughes and ConocoPhillips, was to have been made available to project participants in March 2013, and to the public in September 2014. Recent case studies describe how field implementation of the U.S. National Geophysical Data Center’s new high-definition geomagnetic model (discussed in the 2012 article) helped achieve greater MWD survey accuracy in long ERD wells.5,6 LOGGING WHILE DRILLING (LWD) The next several sections highlight LWD advancements, in the areas of acoustic logging, electromagnetic logging and nuclear logging. Acoustic logging/Cement evaluation. Within defined technological limits, LWD acoustic devices can provide time-saving, cost-effective, basic cement evaluation, e.g., top of cement, and a qualitative indication of cement bond quality. They can also provide casing collar location, such as in setting cased-hole whipstocks. Depending on requirement and objectives, LWD cement evaluation can be made while tripping in or out of the well, and it may replace a separate wireline run. This method is particularly effective in large-diameter casing, and where wireline conveyance can be difficult. In high-angle and horizontal wells, the stiffer LWD collars are less subject to eccentering than a wireline tool. LWD top-of-cement evaluation compares very well with wireline evaluation over the same cased interval, and can indicate whether more advanced logging techniques must be deployed or can be avoided.7,8 Acoustic logging/Azimuthal acoustic device. Weatherford’s CrossWave LWD azimuthal acoustic tool measures shear-wave anisotropy, as well as compressional- and refracted shear-wave slowness. The primary design objectives are determination of shear-wave anisotropy and providing borehole images in horizontal shale wells. The unipole configuration consists of a single, azimuthally-focused transmitter, an acoustic isolation (attenuator) section, and a single array of six directionally-focused receivers (Fig. 1) that are azimuthally-aligned with the transmitter. The receiver array is 6 ft long, and the inter-receiver spacing is 6 in.

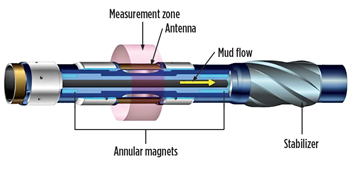

Unlike conventional monopole tools, which are radially symmetric, the directionally-focused tool can measure the velocity profile of an anisotropic formation by differentiating the slowness of refracted compressional- and shear-waves from different azimuthal directions around the borehole. The transmitter operates at 10 to 12 kHz, and compressional- and shear-waveforms are acquired by the six receivers in 16 azimuthal bins. The azimuthal data are processed to produce compressional- and shear-wave borehole images. These are then used for determining fast and slow shear-wave slowness; azimuth; and the anisotropy ratio. Similar to conventional monopole measurements, the shear-wave measurement is only available, when the formation shear-wave velocity is faster than the compressional-wave velocity of the borehole fluid (typically not an issue in shale formations). However, since the azimuthal refracted shear-wave measurement is not significantly dispersive, the need for frequency- and borehole-dependent dispersion corrections, which are required for dipole flexural-wave measurements, is eliminated. The tool also does not need to be centered in the borehole. The compressional- and shear-wave-derived borehole images compare well with similar images derived from LWD azimuthal density and gamma-ray measurements, and the tool can be used in geosteering, if data are obtained in real time.9,10 Electromagnetic logging/Magnetic resonance. Schlumberger has developed and field-tested a new series of LWD NMR tools for 6.75- and 8.25-in. collars. The new tools, based on the same architecture as the firm’s current LWD-NMR series, incorporate significant improvements in antenna design, acquisition techniques, quality control and data processing, and can provide measurement quality comparable to wireline NMR tools. The tools use mud turbines for power and operate in real-time or memory mode while drilling or sliding. The tool configuration, involving a single NMR antenna positioned between oppositely polarized permanent magnets (Fig. 2), and the choice of operating frequency (250 to 270 kHz) are designed to generate the low-field gradient and high SNR. These tools acquire T2 as the standard measurement—the effects of lateral motion on the measurement are minimized through the use of stabilizers, as well as the low magnetic field gradient. The tool employs a short minimum echo-spacing (0.6 msec) and dual-burst acquisition sequences, which provide improved accuracy and precision. The cylindrical sensitive volumes have diameters of investigation of 14 and 17 in., for the two respective tool sizes. Based on typical drilling rates of penetration (ROP), the axial resolution is between 2 and 3 ft. In harder formations, where ROP is lower, axial resolution may reach 1 ft. The 6.75-in. tool is designed for use in borehole sizes between 8.5 and 10.5 in. A prototype of the 8.25-in. LWD NMR tool has been run successfully in a 12.25-in. diameter test well. The primary products provided by the tools are total porosity, bound-fluid volume, and permeability.11

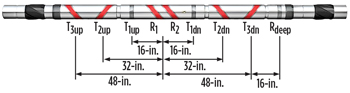

Electromagnetic logging/Azimuthal resistivity. Halliburton is developing a new azimuthal resistivity sensor (ADR-TT) that uses both tilted transmitters and receivers, allowing it to measure formation anisotropy in any drilling environment. Current azimuthal-resistivity tools that use only tilted antennas (see 2008 article) are designed to record formation anisotropy in high-angle and horizontal wells. The new tool, which has two central tilted receivers, four tilted transmitters, and two non-tilted transmitters (Fig. 3), has similar capabilities to conventional LWD resistivity tools in horizontal wells. However, the new design can also provide resistivity anisotropy measurements, i.e., horizontal and vertical resistivity, and the relative dip angle, in vertical and low-angle wells. The multi-frequency sensor has T-R spacings of 16, 32 and 48 in. Tool processing can also provide conventional LWD compensated resistivity and the azimuthal Geosignal.12,13 The acquisition of data in real time makes the tool useful in geosteering and well placement applications, as well as formation evaluation.14

Navigate Energy Services has introduced a novel MWD/LWD system that is delivered to the well site fully assembled (34 ft long), and interfaces with a surface system that allows remote operation and drilling automation, and is designed to be run completely unmanned. This system is designed specifically to provide geosteering and well placement capability in unconventional reservoirs, e.g., shale, while meeting the tight cost requirements in this drilling environment. The system provides the information required for precise wellbore placement, drilling dynamics for efficiency, annulus pressure to assist with MPD and formation measurements for geosteering. The MWD sensors provide survey, continuous inclination, and drilling dynamics measurements. The LWD sensors provide total gamma-ray and azimuthal gamma-ray images for geosteering; and an optional propagation-resistivity sensor that employs a third and longer T-R spacing (19.5, 29, and 48 in.), and a third and lower frequency (100 and 400 kHz and 2 MHz) to achieve a deeper depth of investigation. Real-time data can be provided by either mud-pulse or electromagnetic telemetry.15 Electromagnetic logging/Formation sampling while drilling. Several recent papers provide additional technical details and operational procedures, and discuss field applications for the new sampling-while-drilling tools covered in last year’s article.16,17 Nuclear logging/At-bit gamma-ray sensor. Schlumberger has introduced an at-bit azimuthal gamma-ray sensor for use in geosteering/well placement of horizontal wells and long laterals. The tool consists of two subs—the sub containing the gamma-ray measurement sensors is placed immediately behind the bit in the bottomhole assembly, and the second sub, a wireless (electromagnetic) telemetry sub, is placed above the mud motor. The second sub is used to transmit data across the mud motor for transmission to surface via conventional mud-pulse telemetry. Typically, LWD sensors are placed above the mud motor and may be 40-plus ft above the bit. Placing LWD sensors as close as possible to the bit (see 2010 article) a) reduces the reaction time; and b) allows continuous data (image) acquisition during sliding, as the measurement sub rotates with the bit, which can result in more accurate, efficient geosteering. The azimuthally-focused scintillation detector samples gamma counts 100 times per second. A set of magnetometers and accelerometers provides a measurement of (azimuthal) detector position. Real-time data are typically presented as eight-sector images that provide feature identification from which dip angle and direction can be calculated; memory data are typically presented as 16-sector images. Additional at-bit measurements include stick-slip severity and measurement sub RPM for use in improving drilling efficiency. The data display includes MWD survey station inclination, which allows monitoring of motor yields while sliding, and build/drop tendencies of the drilling assembly while drilling in rotary mode.18 Nuclear logging/Integrated multifunction tool. Schlumberger’s latest, integrated, multifunction LWD service (NeoScope) eliminates all radioactive sources (AmBe and cesium-137) and uses a pulsed-neutron generator (PNG) for all nuclear measurements. This is particularly important for safety in transportation and handling at the wellsite, and where governmental regulations prohibit using downhole chemical sources. The tool is very similar in size and capabilities to the current multifunction LWD service (EcoScope) (see 2006 article). The new service provides traditional triple-combo measurements, i.e., thermal-neutron porosity; neutron-gamma density (NGD); and conventional dual-frequency (400 kHz and 2 MHz) propagation resistivity, as well as elemental capture spectroscopy; thermal-neutron capture cross-section (sigma); azimuthal gamma ray; ultrasonic caliper; annular pressure and temperature; drilling dynamics measurements (triaxial shocks and vibration); and near-bit inclination. All the services are contained in a single, 6.9-in. diameter, 26-ft (7.9-m) collar, for use in 8.5-to-9.0 in. boreholes. The nuclear and resistivity sensors are collocated, i.e., they measure the same formation volume simultaneously. Conventional formation bulk density, which is measured using a cesium-137 chemical source, is a gamma-gamma density measurement (GGD). The formation-density measurement acquired using the PNG is a neutron-gamma density measurement (NGD). The NGD measurement uses high-energy inelastic neutrons produced by the PNG to excite gamma-ray generation in the formation, which are then detected to determine formation density in a manner similar to the GGD measurement.19,20 While the NGD measurement is not new—the EcoScope service uses both a PNG and a chemical source, and acquires both NGD and GGD measurements21—it has been commercialized with the introduction of the new service after years of extensive testing and characterization. The NGD measurement can replace GGD measurement in some borehole applications.

Achieving the environmental benefits that come with development of a true “sourceless” tool involves technical tradeoffs that can impact both geosteering and formation evaluation. Elimination of the cesium-137 chemical source means elimination of the azimuthal-density measurement and density images—unlike a chemical source that can be focused through tool design, a pulsed-neutron source is not focused. Although the NGD measurement is similar to the GGD measurement, and has the benefit of a greater depth of investigation, it also has lower axial resolution, accuracy, and precision, Table 1. WIRELINE LOGGING The next several sections describe advancements made in wireline logging for openhole and cased-hole applications. Openhole/Acoustic. Single-well acoustic imaging is an intermediate-scale technique that can provide information on near-wellbore (10 to 15 m) structural features. The concept and principles were covered previously (2007 article). This technique can be used to complement existing seismic, logging, and core techniques, and improve characterization of near-wellbore features. Two recent papers provide examples, showing how the concept is moving into field applications. In the first case, the technique was used in fracture characterization in a tight-oil shale well.22 In some cases, the acoustic reflections agreed with fractures identified by other methods (core or borehole images), e.g., the technique confirmed the presence of fractures and a fault identified by other methods (core and/or borehole images). In another case, it did not—it identified drilling-induced fractures that were misclassified as naturally occurring in borehole images. In the second case, acoustic single-well imaging was tested as an alternative to conventional electromagnetic ranging methods.23 Acoustic ranging provided information on well location and direction to target consistent with MWD magnetic but provided a more accurate distance to the target. Acoustic single-well imaging can detect boreholes without magnetic or conductive casing and can work in configurations, where active EM ranging is poor, e.g., where the two boreholes are orthogonal. Openhole/Electromagnetic logging. Borehole radar provides another technique for investigating the near-wellbore region (5 to 15 m). Similar in general concept to acoustic imaging and applying the same physical principles as surface radar profiling (e.g., ground-penetrating radar), borehole radar uses downhole transmitters and receivers to measure the reflection and transmission of radar-frequency (10 to 1,000 MHz) electromagnetic (EM) waves to detect variations in subsurface properties, e.g., fractures, and lithologic and fluid boundaries. Primary applications have been geotechnical investigations in crystalline rocks, ore exploration and mining, surveying salt dome caverns for oil and gas storage, geothermal reservoir detection, and object (e.g., UXO) detection. The receiving antennas register the reflected or transmitted electromagnetic pulse as a function of time. Stationary measurements are taken, as the tool is moved along the borehole, and used to generate a radar reflection profile. The depth of investigation is a function of the conductivity of the rocks and pore fluids—deeper in more resistive rocks—and the operating frequency. Omnidirectional transmitting antennas have a greater depth of investigation than directional antennas, and are typically used for rapid identification of the location, dip, and lateral continuity of fracture zones, while directional antennas are needed to determine the strike of planar reflectors or the azimuth to point reflectors. Borehole radar tools require a nonconductive borehole fluid, and can operate in nonmetallic (nonconductive) cased boreholes. The operating mode can be changed to permit the system to operate in single-well reflection, crosswell reflection, or cross-well tomography mode. Until recently, borehole radar tools were stand-alone tools that used an optical cable connection to the surface equipment, and had relatively shallow depth restrictions (=150 m), due to the pressure and temperature limitations of the materials used in the tool design (fiberglass housing). Recent advances include systems that can operate on conventional seven-conductor armored logging cable, and at deeper depths (up to 2,000 m), and may have a rotating antenna system that provides a continuous 3D image of the near-wellbore region. One tool prototype has been designed for oilfield use and can be run as part of a logging toolstring.24-27 Openhole/Geomechanics. Correlations between sonic travel time (delta-t or DT) and bulk density (?b or RHOB) in sand-shale sequences are widely used to derive rock density from compressional-wave velocity or the inverse, compressional-wave velocity from density data. A recent study re-examined this correlation and tested it, using datasets from several fields in the Gulf of Mexico (GOM) and North Sea.28 The linear correlations found, both in the GOM and North Sea data, confirm the validity of Gardner’s correlations for use in hydrocarbon reservoir rocks. Openhole/Geochemical logging. Schlumberger’s Litho Scanner is the latest entry in openhole geochemical logging. This tool incorporates a nonchemical pulsed-neutron generator (see 2007 article) and a lanthanum bromide detector (see 2009 article). Use of a neutron accelerator offers the safety features of “sourceless” logging (discussed in previous articles) and combines the benefits of capture spectroscopy (sigma) and inelastic gamma-ray spectroscopy (C/O logging) (similar to cased-hole PNL devices) thus enabling determination of a wider range of elemental concentrations (Table 2) and mineralogy.

The high-output 14-MeV pulsed-neutron generator uses hot-cathode technology to generate crisp neutron bursts that allow clean separation of the inelastic and capture gamma rays, thereby improving measurement quality. The tool provides improved measurement accuracy and precision, and logging speed. The tool employs a single, large, cerium-doped lanthanum bromide (LaBr3:Ce) scintillation gamma-ray detector that is very fast and has excellent spectral resolution and high-temperature performance. Elemental data are now provided for magnesium (to help differentiate calcite from dolomite), and accurate measurement of carbon allows a direct measurement of TOC. The smaller, 4.5-in. tool is designed for use in borehole sizes between 5.5 and 24 in., in all mud types. Maximum logging speed is 3,600 ft/hr. The tool is rated to 20,000 psi and 350°F, and is compatible with most wireline openhole services. The commercial introduction follows extensive tool characterization and field testing.29 Open hole/Wireline formation testers (WFT). Schlumberger introduced a new compact WFT probe design (Saturn) that increases wireline formation testing efficiency in unconsolidated, heavy oil, and low-mobility (permeability) formations, e.g., tight sandstones and low-resistivity carbonates. The design uses four openings (self-sealing suction probes) spaced radially around the tool (Fig. 4) that each provide a significantly larger flow area than other probe designs and minimize the storage volume, allowing faster cleanup and sampling, and pressure surveys in very-low-permeability formations. The greater contact with the formation allows the tool to improve fluid-flow rate and differential-pressure measurements in these formations, achieving more accurate oil-water delineation and more accurate permeabilities via pressure-transient analysis. The radial probe design extends the tool’s operational range in both low- and high-mobility formations—zones as low as 0.04 md/cp have been successfully tested, and uncontaminated samples of 7.5° API heavy oil have been recovered from an unconsolidated sandstone. The 4.75-in. probe is designed for operation in borehole sizes between 77/8 and 91/2 in. and is rated to 350°F and 20,000 psi, with an 8,000-psi differential-pressure rating between the flowline and the hydrostatic pressure.30

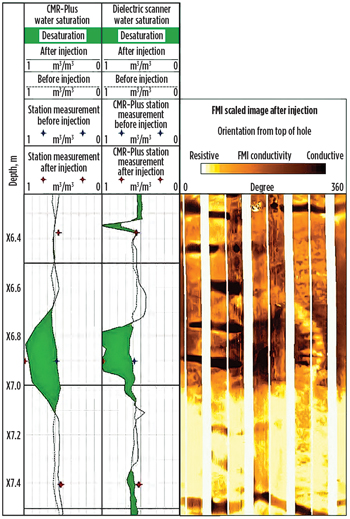

Openhole/Reservoir connectivity. As a result of recent field experience and research, there is a growing recognition that hydrocarbon reservoir architecture, and the fluids they contain, can be more complex than earlier thought. In fact, this complexity may be the norm. Reservoirs often contain multiple compartments and barriers that affect reservoir connectivity, and reservoir fluids can undergo dynamic processes that can lead to significant lateral and vertical variation in their properties. Detecting these variations in a cost-effective, timely manner, and understanding their ramifications in terms of reservoir connectivity, is vital to assessing reserves, field management and production planning, particularly in the deepwater environment with its huge capital costs. Understanding variations in asphaltene concentrations helps improve the assessment of reservoir connectivity: A homogeneous asphaltene composition (compositional equilibrium) can indicate good reservoir connectivity, whereas variations in asphaltene composition (compositional gradients) may indicate the presence of pressure compartments and baffles. Modern WFT devices employing advanced downhole fluid analysis (DFA) techniques provide real-time quantitative measurements of oil color (optical density) and GOR, two key parameters used in determining asphaltene stability and gradients. Shell and Schlumberger have been investigating this subject jointly. They recently published a series of papers discussing a new thermodynamic model that can predict asphaltene concentration gradients, using parameters obtained through DFA, as well as applications of this model in volatile oil/condensate gas reservoirs with large GOR variations, and black oil/mobile heavy oil fields.31-33 Openhole/Single-well EOR evaluation. Schlumberger has introduced a service (MicroPilot) to provide small-scale, in-situ EOR evaluation that can rapidly screen various chemical mixtures and specific lithologies for applicability, prior to committing to more expensive, time-consuming single-well tracer tests or pilot injection projects. In effect, this service performs an in-situ flooding experiment that is intermediate in scale between a laboratory coreflood and a full-scale single-well test. The openhole service is a variation of the log-inject-log procedure and requires two to three days.

After a well section is logged, a drilling module, which is an openhole version of the cased-hole formation tester, drills a pencil-sized hole (9 to 10 mm) 15 cm into the formation, produces formation fluids to clean out the hole and then injects several gallons of EOR test fluid that it has transported downhole—in effect the reverse process of formation sampling operations. Two optical fluid analyzers monitor the produced and injected fluids for contamination, and the buildup of reservoir pressure following the initial formation flow period is used to derive fluid mobility. Following this stage, the borehole interval is logged again. Dielectric, NMR, and borehole imaging tools are used to acquire the before- and after-injection logging measurements, which provide an in-situ measurement of the change in residual-oil saturation near the wellbore and the EOR flood geometry, Fig. 5.34-36. REFERENCES 1. De Wardt, J.P., et al., “Wellbore collision avoidance and interceptions—state of the art,” SPE paper 163411, presented at the 2013 SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, March 6-7, 2013.

|

|||||||||||||||||||||||||||||||||||||||||