STEPHEN HALL, Tata Steel

|

| The Williams Perdido Norte project required over 194 mi of X65 pipe, set at water depths of over 8,000 ft, on exceptionally rugged seabed terrain. Photo courtesy of Tata Steel. |

|

Deepwater linepipe is usually small-diameter, thick-walled pipe, which is by definition a pipe with a high thickness-to-diameter (t/D) ratio. For pipe manufacturers who deploy the UOE process, in which steel plate is first pressed into a U, and then an O shape, then expanded circumferentially, the creation of linepipe with a high t/D ratio represents the greatest challenge. As the limit state for the design of such pipe is not guaranteed to be collapse, the manufacturer has to produce a high t/D linepipe that can meet the most demanding limit-state requirements, with any specific collapse element coming through extra testing.

For low-t/D linepipe, the predominant collapse mechanism is elastic, controlled primarily by the pipe’s dimensional performance. For high-t/D pipe, one of the most frequently dominant collapse mechanisms that influences the design is plastic collapse. This is controlled by the mechanical strength and shape of the linepipe.

The key factors for the manufacture of a deepwater linepipe are the consistency of both the dimensional and mechanical properties around the circumference, and along the full length of the pipe. The pipe manufacturing route can significantly influence a number of factors in the DNV OS-F101 collapse equations, which, when optimized, can yield improvements in the collapse resistance of UOE pipe. Understanding the design requirements and the UOE manufacturing process are essential in manufacturing a product that exhibits all the desired qualities, so that if the intrinsic collapse resistance of the pipe can be increased, there are benefits of cost reduction, increased safety margins, and facilitation of laying at greater depth and speed.

A model solution. Due to the stringent requirements for deep water, it is essential to be able to manufacture high-t/D pipe of the necessary quality, but in a commercially viable production environment. Each step of the forming process must be fully understood from a theoretical and operational perspective. Finite element (FE) modelling and validation of the individual processes within the UOE manufacturing route allow the dies for each step of the process to be designed at the optimum specification. This is essential to giving good shape to the final pipe, at a commercially viable production rate.

The UOE forming processes for high-t/D linepipe involve large amounts of pressure, and the possibility of damaging equipment is high, if the process is not controlled. The use of modelling that has been validated on previous projects allows the design of the pressing dies to be optimized. This optimization allows the minimum level of force necessary to be used, thereby reducing the risk of damage to the equipment.

In UOE manufacturing, each of the individual forming processes has an impact on the others. An understanding of these interactions is necessary to establish a process that is optimized to deliver quality pipe. For example, a good crimp profile for shape control in the O-press allows consistent weld preps and reduces peaking in the final product. This not only affects the final product quality in terms of shape (since peaking cannot be fully removed by the expander), but can have a large impact on the throughput of the mill by allowing the welding process to be set up for optimum running. FE modeling allows the design of dies that not only give the correct shape and profile but, due to the custom nature of the process, reduce the amount of wear. This gives better shape control while reducing the costs associated with lower quality and throughput.

Modelling and validation are essential tools for understanding the UOE process as it relates to high-t/D pipe. Strain reversals on the material during the forming process in the UOE mills are unavoidable, and necessitate the de-ration of the pipe manufactured through this process, due to the Bauschinger effect. This fabrication factor for the pipes is a calculated value, which should be used as a design tool only, and not as a quality control tool. Quality control for the product should be determined by whether the actual test results meet the calculated tensile and compressive minimum yield strength, as set out in the specifications.

Application of technology. Tata Steel was the sole supplier of 18-in. linepipe for the Williams Perdido Norte project—one of the world’s deepest pipelines. The company delivered 312 km (194 mi) of uncoated steel linepipe, for use in ultra-deep water, ranging from 3,500 to 8,300 ft, with a rugged seabed, overcoming a variety of obstacles along the way.

The most challenging aspect of the Perdido Norte project was the sheer depth of water where the pipeline was to be laid. The design was thoroughly investigated, and opportunities for optimizing the required wall thickness of the pipeline were evaluated. A pipe grade of X65 was chosen, considered to be the best balance between strength and weldability, to allow the economical installation of the 320 km of pipeline. The pipe was manufactured to withstand a service rating equivalent to ANSI 1500.

The pipe was 18 in. in diameter, ranging from 19.1 mm to 27.0 mm thick (about 0.75–1 in.). One section of the pipeline is now being used to transfer hydrocarbons from the FPS host in Alaminos Canyon 857 to the termination point in East Breaks Block 994—a distance of 78 mi. The gas pipeline runs for 106 mi and terminates at Williams Seahawk pipeline in East Breaks Block 599.

The Perdido Norte was the most challenging that Tata Steel has been involved in, and it set a benchmark in terms of what could be achieved with a thoroughly and efficiently planned process. The depths were particularly challenging, especially when coupled with uneven terrain. The deepwater pipeline industry will continue to evolve, with some projects that will require working at depths greater than 10,000 ft. There is much to be learned from the success of the Perdido Norte pipeline project, in terms of pipe development, that will apply to successful projects at greater depths.

The way forward. A natural progression within the industry has been to develop higher-t/D-ratio products at X65 strength. The next logical step is to increase the specified grade to X70, to give more mechanical resistance to collapse. As previously mentioned, the manufacture of high-t/D linepipe involves the application of large forces during each stage of the UOE forming process. An increase in strength of the starting plate material will require even larger forces to be applied during the forming stages than required for X65 material. To prove the UOE process for the manufacture of a high-t/D pipe, it is essential that the manufacturer understands the dimensional and mechanical properties of the pipe along its entire length, as the in-service pipeline will be subjected to large external hydrostatic pressure along the whole length during its operational lifetime. To understand this phenomenon and what the pressure variation is at various points around the ring, a trial was carried out to quantify the differences, both around the circumference and along the full length of an X70 grade pipe, and to demonstrate the consistency of the UOE manufacturing process.

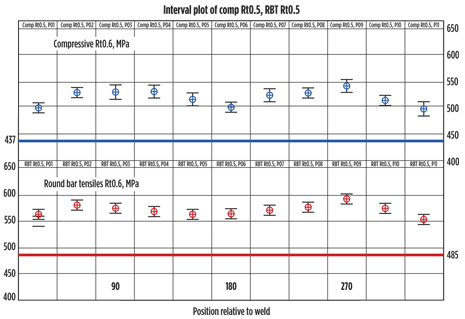

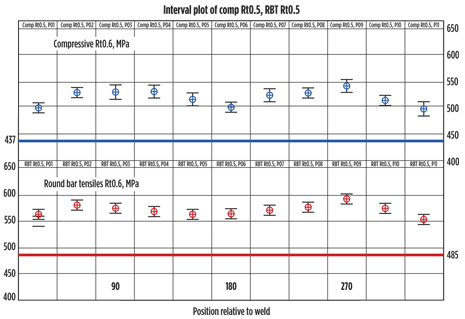

Test success. The mechanical property data for the manufactured pipe showed a normally distributed X70 tensile and compressive yield strength at Rt0.5, which comfortably exceeded the 0.85 fabrication factor associated with the UOE process. The testing regime showed that the properties were consistent, regardless of the position along the length of the pipe. However, there was some variation seen in tests taken around the circumference of the ring. This is due to the different stresses of the individual processing stages, Fig. 1. Production tests were carried out at the 180° position relative to the weld, and all passed the requirements. Tests performed at this location were assumed to indicate the minimum performance for the entire pipe.

|

| Fig. 1. Yield strength of X70 linepipe around circumference of the ring. |

|

Practical application testing of collapse resistance should be carried out in a way that ensures a valid result, but with a reasonable turnaround time. There are three main collapse tests with varying degrees of conservatism and viability for production. The first and most service-realistic option is the full-scale pipe collapse test. However, this method is impractical for use with production testing, due to cost and logistics. Validation of the UOE manufacturing method, and benefits associated with low-temperature heat treatment of the coating process, have been reported.1 This work has shown the relationship between the different methods, and how there are varying degrees of conservatism associated with each. The preferred production release test is small-scale compression testing, which is the most conservative of the three options. The small-scale test pieces can be taken as part of the routine release tests, and results can be generated on a sensible time scale. The test is carried out as per ASTM-E9, with the material sampling done in a way that ensures that all of the grain size variation in the material is sampled equally.

The other subtle consideration is the strain rate of the test. Current experience and calibrations for mills are based on the ASTM-E9 strain rate, and this should be maintained for any tests that are carried out. Another test, which falls between the full-scale and compression tests in terms of conservatism, is the small-scale ring collapse test. This not only allows the mechanical collapse strength to be tested, but also the influence of any imperfections in the shape of the pipe or ring. This test gives a useful result, due to the fact that a ring of the material is tested, and can also be carried out at a sensible testing rate on an extended basis (e.g., 1 in 10 heats).

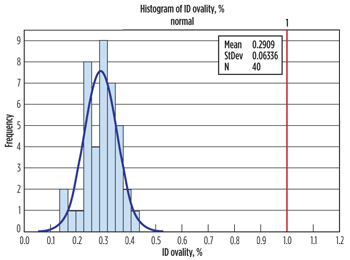

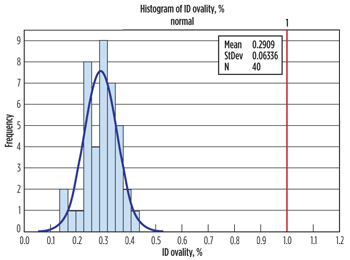

Dimension data. Another important factor for high-t/D pipe is the dimensional performance along its length. A major factor in the collapse limit state equation is the ovality of the manufactured linepipe, with a perfect circle giving the best collapse resistance. The dimensional properties based on the outside diameter ovality of the trial pipes are shown in Fig. 2.

|

| Fig. 2. Ovality (%) of X70 linepipe. |

|

The performance of the UOE process is excellent, with an ovality level of less than 0.5% of the outside diameter. This level of ovality will have a positive impact on the fit-up of the linepipe for laying operations, and also on the collapse resistance of the operational pipeline. All other dimensional measurements taken during the trial showed the excellent performance of the UOE process against the applicable standards.

REFERENCES

1. Slater, et al., “Recent developments of enhanced collapse resistance linepipe,” Paper 4, 18th JTM, May 2011.

|