OTC 2013 to focus on offshore regulation, expanding role of NOCs

With activity in the Gulf of Mexico back to pre-Macondo levels, and a plethora of new deepwater discoveries off Brazil, West Africa, Southeast Asia and the Eastern Mediterranean, a special emphasis is being placed during OTC 2013 on industry self-regulation, government policy and the increasing role of NOCs around the world.

|

NELL LUKOSAVICH, Senior Editor With activity in the Gulf of Mexico back to pre-Macondo levels, and a plethora of new deepwater discoveries off Brazil, West Africa, Southeast Asia and the Eastern Mediterranean, a special emphasis is being placed during OTC 2013 on industry self-regulation, government policy and the increasing role of NOCs around the world. OTC 2013 will be held May 6–9, at the Reliant Park complex in Houston, Texas. Attendance totaled 89,400 people from 110 different countries at last year’s show—the third highest level of attendance since 1982, when 108,161 visitors attended OTC. More than 2,500 exhibiting companies from 46 countries filled the exhibition area’s 641,350 sq ft, which exceeded the 1982 record of 631,000 sq ft of exhibit space. In 2013, OTC will break the record again, with an expected 650,000 sq ft of exhibition space to be used. Annual OTC dinner. The 2013 conference will host the third Annual OTC Dinner, which, for the first time ever, will be held on the floor of Reliant Stadium instead of at the George R. Brown Convention Center. The Annual OTC Dinner, on Sunday, May 5, from 5:30–10 p.m., recognizes the OTC Distinguished Achievement Award recipients, raises funds for the Offshore Energy Center, and provides an opportunity for industry leaders to network with colleagues from around the world. The Offshore Energy Center is a nonprofit organization dedicated to increasing awareness of the vast energy resources beneath the world’s oceans, and to chronicle the unique heritage and technological accomplishments of the industry that discovers, produces and delivers these resources in a safe, environmentally responsible way. These programs are carried out through the Ocean Star Offshore Drilling Rig Museum and Education Center, the Offshore Pioneers Hall of Fame, and its educational program for students, teachers and the general public.

Awards presentation. Ken Arnold, a 48-year veteran of offshore safety practices and oilfield facilities engineering, will receive the 2013 OTC Distinguished Achievement Award for Individuals during the Annual OTC Dinner on Sunday, May 5. Arnold will receive the award in recognition of his outstanding leadership and extensive contributions to the E&P industry. His many achievements include playing an integral role in the offshore industry’s focus on safety through the development of recommended practices for offshore design and safety management, and developing approaches to both equipment sizing and facility project management that are still in use today. Arnold has also been instrumental in the effort to establish oilfield facilities engineering as a recognized technical engineering specialty. Also at the dinner, Total will receive the Distinguished Achievement Award for Companies, Organizations and Institutions. The company is being recognized for its Pazflor deep offshore development in Angola. Now 18 months into production, Pazflor is one of the world’s largest, most sophisticated deep offshore developments to date. In addition to the first use of subsea separation and pumping on a wide scale, the project included the construction of the world’s largest FPSO, and one of the most complex subsea networks. Pazflor made a significant contribution to industrial development in Angola, with 3.5 million man-hours of work undertaken locally. The field started up one month ahead of schedule in August 2011. Ethics breakfast. Held on the morning of Monday, May 6, the ethics breakfast will be led by Barbara Thompson, senior V.P., Front End House of Aker Solutions, and Dan Tearpock, chairman, CEO and founder of Subsurface Consultants and Associates. Entitled “Ethics in the dynamic offshore industry,” the session will explore how offshore companies—and their employees—must deal day-to-day ongoing operations and how organizations can approach ethics in challenging environments. Next Wave program. The Next Wave program, designed for upstream professionals under age 35 and companies interested in recruiting them, will take place on Monday, May 6, from 9 a.m. to 2:30 p.m. The 2013 event, entitled “Global energy outlook: Adapting to evolving energy portfolios and shifting demands,” will offer insight on how unconventional and renewable resources will contribute to the energy mix, and how it might impact the conventionals market. Discussion will include how developing countries are expected to fuel their growing economies, from a resource perspective and an infrastructure standpoint. The keynote speaker, Helge Haldorsen, V.P. of strategy for Statoil, and panelists will discuss the global energy outlook for oil and gas companies, as needs shift globally and new markets open up, and what it means to young professionals coming into the energy industry. Featured panel discussions. This year’s show will feature a series of presentations, including a panel discussion on the expanding role of national oil companies (NOCs), where a panel of executives from Petronas, Petrobras, Pemex and others will talk about their increasing responsibilities and role within the global industry. On Monday, May 6, a panel discussion will focus on DeepStar, an operator-funded, global R&D collaboration between oil companies, vendors, regulators and academic/research institutes, which started in 1991. DeepStar’s current Phase XI program is focused on global deepwater development in water depths to 10,000-plus ft. The organization leverages financial and technical resources to define and rank important deepwater technology needs, deliver technologies via a well-honed stage-gate process, build deepwater technical competency, and execute development and adoption of deepwater technology projects. Greg Kusinski, DeepStar director and Chevron senior advisor to DeepStar, will lead the discussion. Panelists will include representatives from BP, Chevron, ConocoPhillips, Petrobras, Total E&P, FMC Technologies and McKinsey & Company. Other 2013 panels will explore the topics of “Agile project management,” “Offshore energy development—Improving federal and state cooperation,” “Global energy outlook—Shaping the future,” “China: Energy, technology and industry,” “Megaprojects—Exploring the opportunities and challenges,” “Integrating stakeholder interests in the global offshore industry,” “Value creation through global technology,” and “Offshore heavy lifting operations—Above and below the waterline.” A series of presentations will be made on the management of major projects. Topics to be discussed include the Cascade and Chinook project; Liuhua 11-1 semisubmersible FPS life extension project; BPZ CX15 offshore Peru; the South China Sea deepwater Liwan project; and the Pluto greenfield LNG development. Technical program. More than 300 papers will be presented during the show’s technical sessions. Program highlights include:

Several topics this year, which have been regularly presented at OTC in the past, will again highlight continuing advancements in technologies that continue to improve and broaden their scope of applicability. These topics include flow assurance, floating LNG, submarine slope stability, next-generation vessels, deepwater metallic risers, ocean mining, composite piping systems, ROV/AUV technology, and subsea processing technology. OTC 2013 will present new applications and solutions for a number of new topics, including subsalt geosciences, Safety and Environmental Management Systems (SEMS), unconventional subsea exploration and mining, deepwater HP/HT well construction, fiber optics, marine geohazards and pore pressure prediction. A topical breakfast and luncheon will also provide an overview on the new discoveries of subsalt resources in Angola and natural gas in Mozambique. For a more detailed listing of individual papers in the technical program, please check the listings at http://www.otcnet.org/2013/pages/schedule/tech_program/index.php Special focus: Innovation Norway |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

SPOTLIGHT ON NEW TECHNOLOGY AWARDS

Now in its 10th year, this program will recognize 15 technologies representing 16 companies: ABB, Baker Hughes, Bayou Wasco Insulation, Dow Oil & Gas, PIH, Trelleborg Offshore, FMC Technologies, GE Oil & Gas, Reelwell, SBM Offshore, ShawCor, Statoil, Superior Energy Services, Wärtsilä Corp., Welltec and WeST Drilling Products. Winners are selected on five criteria. First, the technology must be new—i.e., less than two years old, dating from the first time it was introduced to the marketplace or was announced or advertised in a conference, press release or trade journal. If previously advertised at OTC, it must not have been displayed for more than one conference. Second, the technology must be innovative, original, groundbreaking and capable of revolutionizing the offshore E&P industry. For example, an improvement in efficiency of an existing motor would not be considered, unless it had the potential to change the way in which the motor would be used in the industry. Third, the item must have been proven, either through full-scale application or successful prototype testing. Fourth, the technology must have broad interest and appeal for the industry. Lastly, the technology must make a significant impact, providing sizeable benefits beyond existing technologies. Environmental impact is an important judging criterion. The awards will be presented at a special ceremony in Reliant Center at 4 p.m. on Monday, May 6. |

| SPOTLIGHT ON TECHNOLOGY AWARD WINNERS | ||

|

Ram positioning system and ROV subsea display panel GEO Oil & Gas has won an award for its RamTel Plus, which provides operators with a direct method of determining ram position. When closing in a well using a BOP, knowing exactly where the shear and/or sealing elements are positioned is important. GE’s ROV Display allows the ROV to read stack sensor data, including wellbore temperature and ram position subsea indicators. |

|

|

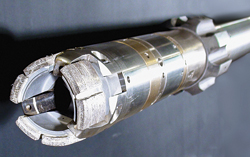

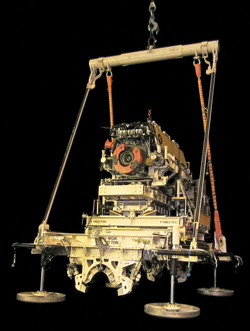

Deepwater BOP blind shear ram GE Oil & Gas also won an award for its next-generation technology for shearing and sealing wellbore tubulars. The patent-pending Blind Shear Ram is designed for use in GE’s ram blowout preventers used in offshore drilling. It provides an industry-first capability to shear some 6 5/8-in. drillpipe tool joints while achieving a wellbore seal holding up to 15,000 psi pressure differential. |

|

|

Explosive-free pipe and casing recovery Welltec won an award for its Well Cutter, which enables efficient drill pipe and casing recovery without explosives. No shavings are generated, a smooth, polished surface remains after the cut and e-line conveyance ensures accurate depth control. The Well Cutter offers a safer, faster, more reliable and cost-effective approach to cutting drill pipe and casing. |

|

|

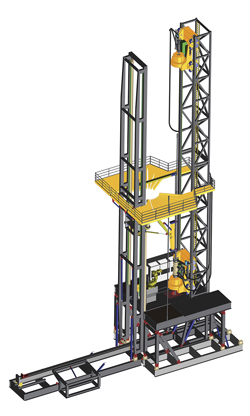

Continuous motion rig reduces drilling time WeST Drilling Products won an award for its Rig of the Future—Continuous Motion Rig (CMR)—which offers the world´s first continuous drilling operation and is also the world’s first fully-robotized rig. CMR reduces the overall drilling time up to 50% and facilitates MPD. CMR substantially reduces down-hole problems associated with differential sticking and pressure fluctuations and eliminates personnel safety risk. |

|

|

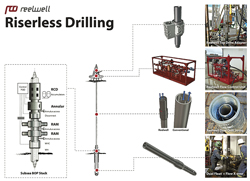

Riserless drilling system for 3,000 m water depths Reelwell won an award for its RDM-Riserless system, which enables drilling in water depths of 3,000 m from 3rd generation drilling units, due to the reduced weight related to omitting the riser. This is possible because the cuttings are transported to surface inside the dual drill string, i.e. the dual drill string acts as the riser. |

|

|

Direct-current power grid reduces fuel consumption ABB received an award for its Onboard DC-Grid, a marine technology that uses direct current to transport energy to different consumers onboard the vessel. It enables variable speed operation of generator sets, significantly reduced fuel oil consumption, improved emission reduction, reduced maintenance and new operational modes with a more responsive vessel system. |

|

|

Renewable offshore power generation Wärtsilä won an award for its GasReformer, which turns VOCs or associated gases that were previously considered as waste into a valuable source of energy. Herewith it enables self-sustaining power generation for the offshore operation. The Wärtsilä GasReformer not only provides cost savings but has the even larger benefit of environmental sustainability. |

|

|

Subsea flow assurance insulation system Bayou Wasco Insulation, Trelleborg Offshore, Dow Oil & Gas and PIH received an award for their DOW NEPTUNE Advanced Subsea Flow Assurance Insulation System. The technology is a simple, robust, end-to-end flow assurance solution, protecting equipment, line pipe and field joints across the widest application and in-service temperature range of any wet insulation system (-40°C to 160°C, or -40°F to 320°F), withstanding hydrostatic compression of ≥400 bar (4,000 m), and offering enhanced performance safety with its simple, two-layer application. |

|

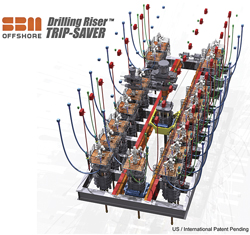

Rail-mounted riser transport system SBM Offshore won an award for its Drilling Riser Trip Saver, a rail-mounted transport system which relocates a suspended drilling riser with a drilling riser tensioner system and surface blowout preventer in-place. This apparatus and method for drilling multiple subsea wells consecutively, saves time, money and reduces risk by avoiding removal of the suspended drilling riser from the well bay. |

|

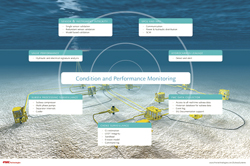

Surveillance system for 24/7 subsea production monitoring system FMC Technologies received an award for its Condition and Performance Monitoring (CPM), a surveillance system which enables proactive maintenance of subsea production and processing systems associated with a 24/7 collaborative expert environment for diagnosis and problem solving. CPM combines continuous monitoring of sensors and subsea instrumentation with a historic database to identify fault condition and deviations from normal operating conditions. |

|

LWD fluid analysis sampling and testing service Baker Hughes received an award for its FASTrak logging-while-drilling (LWD) fluid analysis sampling and testing service, which provides knowledge of reservoir fluid properties that enhance critical decision-making about the reservoir. FASTrak addresses the growing need to acquire fluid samples in LWD environments, such as horizontal or extended-reach wells, resulting in significant time and cost savings. FASTrak services include accurate formation pressure tests, in-situ measurements of reservoir fluid properties and downhole fluid capture and retrieval. |

|

High-speed, helico-axial multiphase subsea boosting FMC Technologies, Inc. and Sulzer Pumps Ltd. received an award for their development of a powerful new high-speed, helico-axial multiphase subsea boosting system optimized for subsea applications. This system combines field-proven pump hydraulics from Sulzer Pumps with FMC Technologies’ permanent magnet technology from Direct Drive Systems for less maintenance with greater speed, efficiency and power. |

|

Mobile robotic cutback system Bredero Shaw won an award for its end-machining technology for insulated pipe, the Mobile Robotic Cutback System. It replaces manual processes that form the cutback including wire brushing, grinding and scraping. The new technology is safer, quieter, requires less labor and produces consistent high quality cutback profiles while generating recyclable waste, all significant benefits to the industry. |

|

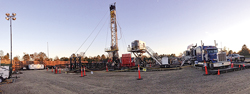

Completion services rig with pre-programmed robotics Superior Energy Services received an award for its Complete Automated Technology Systems (CATS). The technology is an onshore and offshore completion services rig that uses remote-operated or pre-programmed robotics to control various completion components, including a snubbing unit, BOP/well control stack, pumps, circulation tanks, top drive, closing systems and pipe handling systems as part of one unit. |

|

Remotely welded retrofit subsea hot tap tee Statoil received an award for its remote-controlled hot tap operation, which of a robot welding a T-piece on to the pipe, while gas is flowing through it. Afterwards a remote-controlled drilling machine will drill holes in the producing pipeline, with no effect on pressure and production. The hot tap technology has been employed successfully multiple times. |

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)