Drilling advances

Vol. 233 No. 10

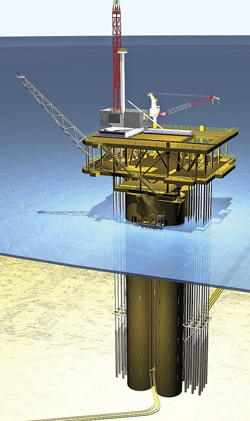

Though it may not carry the panache of a fresh-out-of-the-yard drillship, the developers of a newly minted, shallow-water buoyant tower on location off Peru believe their unique brainchild fills a sorely needed niche in the offshore sector. The one-of-a-kind creation of a 50/50 joint venture between engineering and project management concern GMC, Horton Shallow Water Development and Horton Wison Deepwater, the multi-faceted CX-15 fixed-depth, shallow-water buoyant tower was installed late September on BPZ Energy’s Corvina field. Located in 175 ft of water, the newly engineered drilling and production tower will be connected later this year via subsea pipelines to the existing BPZ CX-11 platform, one mile away in Peruvian offshore block Z-1. The multi-functional platform is outfitted with 24 available drilling slots, though some will be used for constructing gas and water injection wells. What’s more, the tower is designed to produce up to 12,200 bopd with gas compression capacity of 12.8 MMcfd. It also is engineered to handle and inject up to 3,500 bpd of produced water and, if required, can even store as much as 150,000 bbl of oil. The fixed-water-depth and companion variable-water-depth designs capitalize on proven cell-spar technology and, according to the joint venture, resolve many of the economic issues associated with operating in 150–800 ft of water, particularly in more marginal fields. Since the structure behaves much like a compliant tower, it moves in response to environmental forces, making it an especially good fit for near-shore areas with seismic activity. Though the basic features and functions of the two design types are nearly identical, the variable water-depth version incorporates additional elements that allow it to be modified to operate in a range of relatively shallow-water depths. The CX-15 design represents the fixed water-depth version capable of accommodating dry trees and a tender-assist drilling program for up to 24 wells. As with any design employing cell spar technology, the buoyant tower comprises multiple cylindrical tubes constructed with internal bulkheads that create separate water-tight cavities. The cells are filled partially with permanent high-density ballast, while seawater provides variable ballast, which together effectively generates a low center of gravity. A site-specific integral foundation, which holds the tower in position, is customized for the specific soil and environmental conditions. The design is scalable, meaning the precise number and diameter of the individual cells depend on the water depth, environmental conditions and topside weight. The entire structure has net downward load acting on the foundation, but the buoyancy effect reduces the total load to a fraction of the cumulative tower weight. The ballast levels in each cylinder are computer-controlled to ensure the tower remains within ±1° of vertical, allowing the structure to continually exert a positive downward-acting force on the supporting soil. The developers say the economic benefits of the buoyant tower become apparent well before drilling or production begins. After fabrication at the Wilson Offshore & Marine yard in Nantong, China, the CX-15 tower, decks and all production equipment were loaded aboard a submersible heavy-lift ship and delivered to Peru, where the hull and topside simply were floated off in sequence. Once the tower was upended, the fixed and variable ballast was pumped into the hull, making it stable and ready for operation. Since the transport submersible handled the installation, BPZ Energy did not have to shell out for a separate heavy lift vessel or bear the costs for piles and grouting. According to the JV, BPZ Energy chose the buoyant tower design for the economic and scheduling advantages it offered over the fixed jacket design originally considered, which it concluded could not meet the stringent seismic criteria of conditions in the shallow waters off Peru. The immediate area also had a dearth of heavy-lift vessels otherwise required for a conventional drilling and production structure. The tower was on location in less than 13 months after the contract was awarded. Owing to its comparative mobility, the buoyant tower can be relocated when its job is completed at a particular location. The capacity to quickly deliver first oil, exploit a field’s reserves and move elsewhere could brighten the spirits of any operator accountant who may be questioning the economics of producing marginal reserves in a particular field.

|

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Drilling advances (January 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)