ZUBER A. KHAN, BIJAYA K. BEHERA, Gujarat State Petroleum Corporation; VIKASH KUMAR, PAUL SIMS, Schlumberger

Many oil or gas fields are under-evaluated, because their environmental conditions exceeded the capability of available downhole measurement devices. Sometimes high pressure, sometimes high temperature, or both, challenge the most sophisticated instrumentation. Extreme environments can damage or disable downhole tools, and, even more insidious, cause inaccurate measurements. A critical decision made with incorrect data can be disastrous.

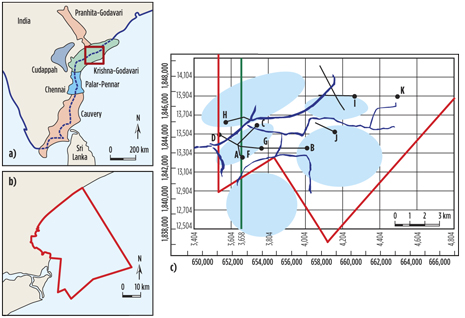

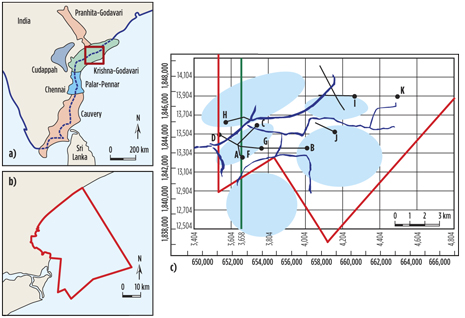

The Gujarat State Petroleum Corporation (GSPC) has made significant discoveries in the Krishna-Godavari (KG) basin. With a large onshore component in the Indian state of Andhra Pradesh, the KG basin extends offshore into the Bay of Bengal off India’s East Coast. In the basin, a highly-faulted horst and graben structure extends from the Endamuru High eastward to the very deep expansion sub-basement. Extensive rifting caused tectonic faulting that, in turn, has created several traps. Advanced Q-Marine seismic exploration and processing revealed the prospectivity of the region. Based on this seismic data, targets were identified in Upper and Lower Cretaceous sequences, Fig. 1.

|

| Fig. 1. The Krishna-Godavari basin is both onshore and offshore India’s East Coast (a, b). A highly-faulted horst and graben structure extends from the Endamuru High eastward to the very deep expansion sub-basement (c ). |

|

The Upper Cretaceous dominant facies type is of marine and restricted marine shale in origin, with fining-up fluvial and tidal channel sands, and isolated bars. Sheet sands of sand-flat and longshore sand spit origin are found in a complex deltaic depositional environment that is quite heterogeneous, together with delta front and tidal flat lithology. The Lower Cretaceous reservoir was deposited under fluvial environments during the rifting phase. Sedimentary sequences prograded eastward in a continental shelf-slope system. The geology is extremely complex. Underlying the Cretaceous sequences are older sediments that are thought to comprise an independent reservoir. This deeper sequence was explored by GSPC.

HIGH POTENTIAL FROM DEEP, HOT SEDIMENTS

One of the GSPC wells hit a 2,624-ft gas column below 18,045 ft, measured depth. It was the first time that gas had been discovered in the lower, older Jurassic sediment section of the massive reservoir. Initial potential was estimated at more than 100 MMscfd. The wireline log data, showing better porosity and permeability in the lower older reservoir than the overlying reservoirs, was proved from the test data. A full suite of hostile environment wireline logs was run in the well. In high-temperature (HT) wells, wireline logs have the distinct advantage of time—they are not exposed to the extreme temperatures as long as LWD or DST tools. Accordingly, excellent-quality wireline logs were acquired to total depth in the well.

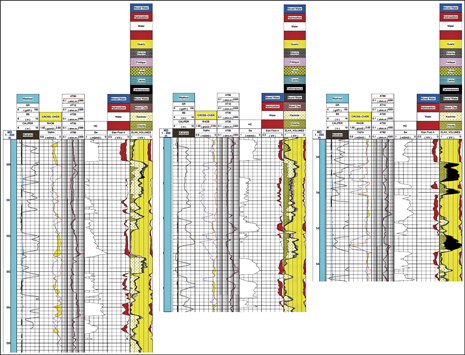

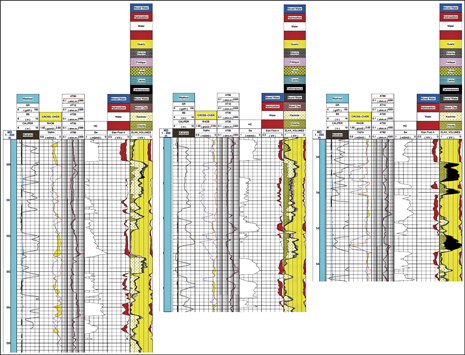

An Array Induction Tool (AIT) was combined with Lithodensity/Compensated Neutron (LDT) and gamma ray tools. The raw data were processed, using the Schlumberger ELAN (Elemental Analysis) program to create a continuous porosity/lithology log and volumetric analysis, Fig. 2.

|

| Fig. 2. Hostile environment wireline logs run to total depth acquired the required data to perform the ELAN (Elementary Analysis) interpretation. A shaly-sand reservoir, characterized by several light hydrocarbon shows with good porosity, encouraged GSPC to continue with a conclusive drillstem test to prove the commercial viability of the discovery. |

|

Numerous pay zones were identified that contained light hydrocarbons. The primary matrix was argillaceous-sandstone, with the clays divided principally into kaolinite and chlorite associated with some bound water. Traces of feldspar and pyrite were observed. Fair-to-good porosity was present in the pay sections. The upper part of the pay section was characterized by several coal seams, ranging in thickness from 6.5 ft to 20 ft.

Permeability in the pay zone is derived from inter-granular porosity and augmented by natural fractures. Pore throats appeared, for the most part, to be unobstructed as clay volumes decreased in the major pay zones. One of the main objectives of the drill stem test was to quantify hydrocarbon mobility to confirm the commercial productivity of the reservoir.

The high-pressure, high-temperature (HPHT) reservoir rock properties, derived from wireline logs and seismic starting below the Lower Cretaceous Unconformity to basement, suggest that reservoir facies are 1,300 ft to 2,600 ft in gross thickness, with approximately 40% net reservoir facies over the entire area. Based on attributes derived from logs, core and seismic, reservoir facies are categorized as good, fair and poor-quality rock. Test data also substantiated the presence of good permeability to support hydrocarbon flow.

The discovery block spans about 723 sq mi, much larger than the typical 9-sq-mi blocks designated in the U.S. Gulf of Mexico. GSPC is the operator, with 80% interest. At the time of the test, the company had drilled 14 wells and planned to drill five additional wells.

MEETING RESERVOIR CHALLENGES

Aside from production data acquired over several years, the best way to determine reservoir volume, permeability thickness, reservoir boundaries and skin effect at the sand face is by drillstem testing.

Some test measurements can be made at the surface, such as multiphase flow-metering, gas volume fraction, etc., but to achieve the desired accuracy needed to revise production potential estimates, downhole pressure transients were needed from which reservoir volumes, flow potential and skin effect could be calculated reliably.

GSPC engineers designed a drillstem test, consisting of at least three successive shut-ins followed by build-ups with continuous pressure measurements, whereby transients could be mapped. Because of the extreme testing environment, the engineers knew they would likely have only one chance at getting the required data.

When drillstem tests are inconclusive, it is usually because they were not prolonged enough to allow the reservoir to reach a stable flow regime. Accordingly, the designers planned a 15-day test duration in an environment estimated at 13,800 psi and 410°F . This would allow for three successive shut-ins and build-ups, each long enough to provide conclusive results. Due to foresight in planning multiple tests and deploying multiple instruments, some operational challenges, with regard to surface instrumentation and water flow, were overcome without the necessity of aborting the test program. As a result, a world record performance was recorded for downhole pressure recorders surviving 15 days at record temperatures.

Five different electronic recording instruments were specified. However, because of their temperature/pressure limitations, three of the gauges had to be located more than 3,200 ft above the other two electronic gauges. The only electronic gauges deemed capable of withstanding the extreme environment at near reservoir depth were Schlumberger Signature quartz gauges. Even so, those gauges were deployed at the estimated 410°F level, rather than at total depth, which was at a temperature beyond the limit of any existing electronic gauge.

QUARTZ PRESSURE GAUGES

Quartz pressure gauges have set the standard of accuracy and precision for many years. Equally capable of measuring static and transient pressure, quartz gauges have evolved to meet the steadily-increasing demands of extreme environments. The Signature 1.0-in. diameter line of downhole instruments consists of three models:

-

TQPR: 16,000 psi, 350°F, 16 MB for up to one year operating life

-

TUPR: 30,000 psi, 350°F, 16 MB for up to one year

-

THQR: 30,000 psi, 410°F, 4 MB for 21 days or 37 days @ 405°F

At the moment, battery life is the critical factor. The instruments, themselves, are capable of operating reliably for longer periods at the rated temperatures.

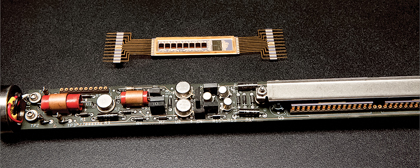

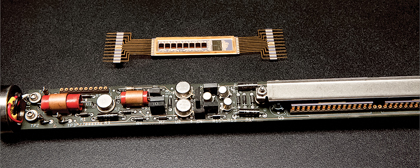

The gauges utilize ceramic, multi-chip module, electronic construction technology. This allows the inclusion of an application-specific integrated circuit (ASIC), condensing the functionality of a large number of electronic components into a single integrated circuit. This capability ensures maximum reliability, optimized measurement resolution and lower power consumption. The ceramic substrate with ASIC, high-capacity memory and long-life battery are the sole internal components of the new gauges.

The new design and miniaturized electronics have allowed the overall dimensions to shrink from 70 in. in length to 19 in., and a new slim diameter of 1.0 in., compared to the previous 1.25-in. diameter. Up to four gauges can be inserted in the 2.25-in. ID full-bore, concentric, H2S-compliant, gauge carrier in the tubing string. These gauges can withstand the severe mechanical shocks encountered when they are deployed with tubing-conveyed perforating systems.

ACCURATE RESULTS

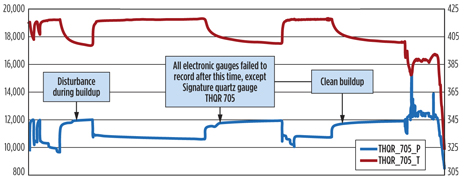

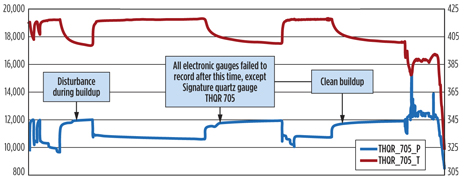

Deployed into the well with the drillstem test string, the Signature quartz gauges were positioned for the 15-day duration of the designed pressure transient tests. Their 4-MB capacity allowed measurement frequency of one complete pressure and temperature measurement every 2 sec over the duration of the test program. Actual well temperature, at gauge depth, turned out to be 418°F. One by one, the pressure transient tests were run. The first two tests encountered some minor mechanical difficulties, unrelated to the gauges. The final test went off without a hitch. When the test string was retrieved, it was discovered that all of the shallower gauges had failed, except for one, the Signature quartz gauge. It was the only gauge to have recorded data during the entire duration of the 15-day test.

The clean build-up transient record from the third test was sufficient for GSPC’s reservoir engineers to calculate the reservoir parameters they needed to achieve their objectives, Fig. 3. Thus, the commercial viability of the reservoir was assured. Without the Signature quartz gauge, no usable electronic data would have been recorded. Because the data recorded were clean and accurate, a second confirmation test was deemed unnecessary.

|

| Fig. 3. Three shut-ins and buildups were recorded over the space of 15 days. Only the final test had a clean buildup necessary for correct interpretation. Only the Signature quartz gauge was operating at that time. |

|

|

| Co-located on a single rugged ceramic substrate, Signature quartz gauge electronics components can withstand the extremes of pressure and temperature for exceedingly long periods. This allows conclusive well test data to be obtained accurately and reliably. Signature gauge electronics (top) are shown in comparison with conventional circuits (bottom). |

|

|

| Dwarfed by its predecessor, the Signature quartz gauge (top), uses less power and records more data at higher pressures and temperatures. |

|

Being able to deploy gauges more than 3,200 ft closer to the reservoir than other gauges improved significantly the reliability and accuracy of the measurements. GSPC engineers credited the successful gauge run with saving $1 million in remedial services that would have been needed to resolve reservoir description issues.

In field cases, the high-resolution Signature quartz gauges have detected pressure fluctuations as little as 0.001 psi. The repeatability window can be lower than ±1.0 psi, compared to the ±7.5 psi error band of standard HPHT gauges.

WIDE APPLICATION PROFILE

By the beginning of 2012, more than 15,000 downhole hours had been logged by Signature quartz gauges, in addition to over 40,000 hours of lab testing recorded at 410°F. The maximum temperature recorded was 418°F, and the maximum field pressure recorded was 19,000 psi (with lab tests to 33,000 psi). About 400,000 individual data sets can be recorded in 1 MB of non-volatile memory, meaning that if there is a total power failure, no data are lost. In addition to India, well tests have been recorded in the Middle East, Europe, Africa, Asia, North America and South America.

|

AUTHORS

|

| ZUBER A. KHAN is a senior manager (geology) with Gujarat State Petroleum Corporation (GSPC). Mr. Khan earned a B.Sc with honors, M.Sc degree in geosciences and PG diploma hydrogeology from AMU in Aligarh, India. He started his career with Geoservices in mudlogging and joined Gujarat State Petroleum Corporation (GSPC) in 2000, where his main responsibilities are focused with the KG offshore HTHP field. |

|

| DR. BIJAYA K. BEHERA is a professor at School of Petroleum Technology in Pandit Deendayal Petroleum University, India. Prior to this assignment, he was working as deputy general manager (geosciences) with GSPC, responsible for E&D projects in the KG offshore HPHT field. Dr. Behera earned his doctorate degree in geosciences from Indian Institute of Technology, Mumbai, India. |

|

| VIKASH KUMAR is the reservoir domain champion for Schlumberger Testing Services based in Mumbai, India. Mr. Kumar began his career with GSPC in 2004 and joined Schlumberger in early 2007 as a reservoir engineer. He received his BS degree in petroleum engineering from the Indian School of Mines. |

|

| PAUL SIMS is a Schlumberger Testing Services product champion based in Clamart, France. He is responsible for leading new product development and introducing surface testing equipment and memory gauges. He joined Schlumberger in 2004 as a field engineer and holds BS degrees in petroleum engineering and finance, both from the University of Western Australia, Perth. |

|

|