MARK A. MCCAFFREY, DAVID K. BASKIN and BROOKS A. PATTERSON, Weatherford Laboratories; DANIELLE H. OHMS and CHRISTOPHER STONE, BP Exploration (Alaska) Inc.; DAVID REISDORF, Alta Mesa Services, LP

Effective field development strategies require operators to know what portion of original resources has not yet been produced. Determining not-yet-produced resources can be a complex challenge when production is commingled from multiple zones. A new technique has been developed that achieves production allocation at a fraction of the cost.

|

| Linda Clancy of Weatherford Laboratories loads an oil sample into the auto-sampler tray of an Agilent-6890 Gas Chromatograph. The instrument can readily separate an oil into ~1000 components, each of which can serve as a "natural tracer" for geochemical allocation of commingled oil production. |

|

Geochemical production allocation is analogous to the following scenario. A glass of water (Water A) contains 100 ppm sodium dissolved in the water. A second glass of water (Water B) contains 200 ppm sodium. When unknown amounts of each are mixed, the mixture is found to contain 150 ppm sodium. Intuitively, we know that the mixture contains 50% Water A and 50% Water B because 150 ppm is the midpoint between 100 ppm and 200 ppm. In this example, the abundance of one chemical component in the water (sodium) made chemical allocation of the commingled water possible. Similarly, a difference in the abundance of any one chemical compound in the hydrocarbons from each of two reservoirs in an oil field is sufficient to serve as a natural tracer for chemically allocating commingled production.

Returning to the example, if a third water (Water C), containing 300 ppm sodium, is added to the mix, then a single, natural tracer is no longer sufficient to allocate the contributions of the three waters to the sample. A second chemical tracer, such as the magnesium concentration, is now necessary. Using the two tracers together, the three-zone allocation problem can now be solved, as long as the abundance of each tracer is different in Water A, B and C. Extrapolated for oilfield operations, for “n” zones being commingled, “n-1” natural tracers are required to allocate the contribution from each zone to the mixture.

IMPROVING GEOCHEMICAL ALLOCATION METHODOLOGY

Chemistry-based allocation of commingled production has been available for more than 20 years, for allocation of production from multiple zones to a commingled production stream in a single well, and for allocation of production from multiple fields to a commingled production stream in a single pipeline. These methods use whole-oil gas chromatography (GC) peak ratios to quantify the contribution of each individual production stream to the commingled production stream. A GC analysis of an oil provides values for the abundance of more than 1,000 naturally occurring compounds in the oil. The abundances of any combination of those compounds can be used as natural tracers for allocating commingled production. The collective abundances form a fingerprint of the oil. The abundance of a given compound in the oil is proportional to the height of a peak on the graphical output of the GC instrument.

If two zones (A and B) were commingled, the respective contributions of the zones to the commingled sample could be determined by identifying chemical differences between end-member oils, with the end members being pure samples from A and B. In the original allocation method, geochemical parameters (GC peak ratios) reflecting these compositional differences were measured in the end-member oils, and in various artificial mixtures of the end-member oils and in the commingled oil. The data were then used to mathematically express the composition of the commingled oil in terms of contributions from the respective end-member oils.

Using that simple mixing model, a single geochemical difference between oils from two sands is sufficient to allocate commingled production from those two units. By using data for several peak ratios, independent solutions to the problem could be derived, allowing the accuracy of the allocation to be assessed.

The original approach for geochemical allocation had two drawbacks. First, it required analysis of artificial mixtures of the end-member oils, because ratios of GC peak heights only mix linearly, when the same absolute value is present in the denominator of the ratio of the two peak heights in all of the end-member oils being mixed. For example, if the ratio of the height of GC Peak A and GC Peak B is measured in three end-member oils and is found to be 7/2 in Oil X, 9/2 in Oil Y, and 9/3 in Oil Z, the value for the ratio of Peak A/Peak B will mix linearly between Oil X and Oil Y, but will not mix linearly between Oil X and Oil Z because Peak B has a denominator value of 2 in Oil X but 3 in Oil Z. Therefore, in the original approach, artificial mixes of end-member oils had to be prepared to determine the shape of the calibration curve that defines how a given GC ratio changes, as one moves from 100% Oil X to 100% Oil Z.

The second drawback to the original approach was that allocation was limited to two or three zones, because, for a given GC ratio, two end members when mixed form a mixing curve, and three end members when mixed form a mixing surface, but when more than three end members are mixed, there is no simple graphical representation of the mixing from which to derive a solution.

An alternate approach was developed that allocates commingled production using a large number of GC peak heights (not ratios) to derive a linear-algebra-based allocation result (as opposed to the original approach that used a small number of GC peak ratios to construct a graphical solution). This new approach does not require analysis of artificial mixtures of end-member oils and can be applied to any number of mixed zones. This new method was automated in a proprietary, geochemical, production allocation software package.

TESTING THE NEW TECHNIQUE

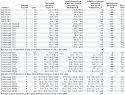

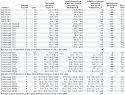

Over a 10-year period, more than 30 blind mixing tests of this new approach were conducted. Various laboratories prepared multiple, artificial mixtures of two to four end-member oils and initially did not reveal the contribution of each end member to each mixture. For each study, the mixed oils and the end-member oils were then analyzed by GC, and an allocation result was calculated. The “true” allocation values were then revealed, and comparison of the true values with the calculated results proved the accuracy of the approach. The blind tests collectively included 32 commingled oils, each prepared by mixing two to four end-member oils. On average, the allocation results differed from the true values by 1.8% for two-zone mixtures, 2.0% for three-zone mixtures, and 2.3% for four-zone mixtures, Table 1.

Field tests were also conducted using the geochemical allocation approach for numerous samples of commingled oils. Allocation results were compared with production logging tool (PLT) results for the same wells. More than 2,200 commingled oils from the North Slope of Alaska have been geochemically allocated over the last 11 years. Two case studies from that area are presented here, as well as an additional example from Oklahoma. Although these case studies are for two-zone allocations, Weatherford Laboratories routinely uses the same geochemical methodology to allocate commingled production from three to six zones.

Well Niakuk-43 (NK-43), Greater Prudhoe Bay, North Slope, Alaska. Well NK-43 was drilled in February 2001. The Sag River (Sag) formation was perforated and tested first. Subsequently, a cast iron bridge plug (CIBP) was set to isolate the Sag, and the Niakuk Oil Pool (NOP, Kuparuk formation) was then perforated and produced.

A blind test was performed, in which the operator provided three artificial mixtures of NK-43 Sag oil and NK-43 Kuparuk oil. The geochemical approach described above was used to allocate the artificial mixtures. After the allocation results had been reported, the operator revealed the makeup of the three artificial mixtures. The differences between the geochemically derived allocation results and the composition of the artificial mixtures reported by the operator were 1.6%, 2.6% and 1.0%, Table 1. The low errors in that blind test led the operator to then try a field study in which geochemical allocation was compared against production logs.

| Table 1. Calculated allocation results compared to actual compositions for artificial mixtures of oils or gases |

|

The CIPB separating Kuparuk and Sag was milled out on Jan. 9, 2006, and commingled production began Jan. 29. During a six-month commingled testing period, four production profiles, 24 geochemical samples, two static bottomhole pressure surveys and 43 well tests were gathered to assess performance of the Sag and Kuparuk intervals. The logging service company interpreted the oil, water and gas splits between the pools. Weatherford Laboratories interpreted oil splits using the new geochemical methodology. Neither company was privy to the other’s analysis or results. A comparison of the commingled oil splits from both the production profiles and oil geochemical fingerprinting is presented in Fig. 1.

|

| Fig. 1. Well NK-43 comparison of geochemistry-derived production splits with Production profile Log (PLT)-derived production splits. |

|

Based on these results, the operator concluded that geochemical analysis provided an accurate method of allocating oil between NOP and Sag. The well operator prepared, for the Alaska Oil and Gas Conservation Commission (AOGCC), a report on the study results and proposed that starting from July 1, 2007, geochemical fingerprinting be used for oil allocation purposes. The AOGCC concurred, and the NK-43 well has been periodically monitored by geochemical allocation since that date. A key advantage of geochemical allocation is that the 24 allocations for this well, performed on 24 different dates, had a combined cost that was less than the cost of any one of the four production profiles.

Well S-26, Prudhoe Bay Field, North Slope, Alaska. Well S-26 penetrates the Aurora Oil Pool and Prudhoe Oil Pool in areas where well rates from both pools are typically low. A stand-alone Aurora producer in this area could not be justified, due to the expected low rates and associated problems with paraffin and hydrate deposition. A rig workover (RWO) was planned to commingle production from the two pools within the S-26 wellbore and maximize oil production from the two pools.

Prudhoe production was isolated on Dec. 15, 2007. The workover was completed in January 2008. Aurora perfs were added, an initial Aurora-only SBHP was obtained, and the well was put onstream on April 4, 2008.

A blind test was performed, in which the operator provided three artificial mixtures of S-26 Ivishak oil and S-26 Aurora oil. The artificial mixtures were geochemically allocated, and the results were reported to the operator, after which the operator revealed the makeup of the artificial mixtures. The difference between the geochemically derived allocation results and the composition of the artificial mixtures reported by the operator were 6.2%, 3.9%, and 4.1%. The low errors in that blind test led the operator to then try a field study in which geochemical allocation was compared against production logs.

During the six-month commingled test period, the well operator obtained production profiles, static bottomhole pressure surveys, geochemical samples and well tests. Two production profile logs, seven geochemical samples, and 19 well tests were gathered to assess performance of the Prudhoe and Aurora zones. The logging service company interpreted the oil, water and gas splits between the pools, and Weatherford Laboratories interpreted the oil splits using the geochemical methodology. Neither company was privy to the other’s analysis or results.

The average Aurora oil split over the commingled test period from the two PLTs was 53%. This value is a very close match (Fig. 2) to the average of the geochemically derived percentage for Aurora oil (55% average for all seven samples), or 53% average for six of the seven samples (i.e., excluding the initial sample when the Prudhoe Oil Pool was just reopened and was cleaning up). Fluctuations in gas-lift rates and wellhead pressures can have an impact on oil production splits from the two zones, explaining the slight variation in the more frequent geochemical analysis, Fig. 2. Furthermore, the geochemical sample obtained on Oct. 10, 2008, and the production profile (PLT) started the same day were over 10 hours apart, explaining the small differences between those points.

|

| Fig. 2. Well S-26 comparison of geochemistry-derived production splits with Production Log (PLT)-derived production splits. The average Aurora oil split over the commingled test period from the two PLT’s was 53%. This value closely matches the average of the geochemical analysis Aurora oil split. |

|

The well operator submitted a report of these findings to the AOGCC. The AOGCC then agreed that geochemical fingerprinting could be utilized routinely going forward for oil allocation of this well.

As in the previous case study, a key advantage of geochemical allocation is that the seven allocations that were performed on seven different dates had a combined cost that was far less than the cost of either of the two PLT profiles.

Oil/gas well, Oklahoma. This example shows the geochemistry-derived production allocation results for oil production from a well in Oklahoma, which commingles production from two reservoirs—Zone 1 and Zone 2, Fig. 3. Application of geochemical allocation to this well was subject to regulatory approval. Prior to commingling production, blind mixing tests were performed. Regulatory approval for commingling was granted, based on successful completion of the blind mixing tests.

|

| Fig. 3. This well commingles production from two reservoirs. Geochemical allocation results demonstrate that during the first year, there were significant changes in the contribution of each zone to the commingled production from the two intervals. These data were acquired at <5% the cost of production logging. |

|

The resources in the two reservoirs penetrated by this well have different equity ownership. Dead oil samples are collected monthly from the well, for geochemical allocation of the contribution of each zone to the commingled sample. The geochemistry-derived allocation results are used to determine monthly revenue payments to equity owners of the resources in the two zones. These monthly, geochemistry-based allocation data are acquired at less than 5% of the cost of production testing. Because this is a pumping well, production logging is not possible. Production logging would require mechanical isolation and individual production testing of each zone. Therefore, were it not for geochemical allocation, the operator would not be able to commingle these zones.

Allocation results from this well during the first year of production demonstrate significant changes in the contribution of each zone to the commingled output from the two intervals, resulting in changing monthly revenue payments to the equity owners of each zone. When commingled production was initiated for this well, the initial allocation results were consistent with expected flowrates from each zone, based on a comparison of allocation data with data for tested flowrates from each zone, when the zones were produced separately. As total output from the well changed over time, the geochemical allocation provided the only way to know the contribution of each well to the commingled production stream.

GEOCHEMICAL ALLOCATION ADVANTAGES

The cost advantages of using oil geochemistry, or oil fingerprinting, versus conventional e-line production logging to allocate commingled production are illustrated in the cited case studies. Geochemical techniques for allocating commingled production from multiple zones in a single well typically result in cost savings of 95% or greater, compared to conventional e-line production logging. The cost savings are even more dramatic when compared to those for coiled-tubing-conveyed or tractor-conveyed PLTs.

The low cost of geochemical production allocation allows field engineers to monitor output frequently over long periods (e.g., weekly, monthly, quarterly), allowing early identification of zone performance problems. The much higher cost of production logging limits that technique to infrequent use. Therefore, production logs typically provide only a snapshot of the production origin at the time the log was run, rather than a continuous performance history.

Geochemical techniques are applicable to highly deviated and horizontal wells, in addition to vertical wells. By contrast, production logging interpretation is problematic in highly deviated wells. Geochemical techniques can be applied to all types of pumping wells, including those with tubing-deployed electrical submersible pumps, and progressive cavity pumps. Other than those with unusual completion styles, such as Y-block completions, most pumping wells cannot accommodate a production logging tool, because the pumping apparatus prevents logging tool access to the underlying perforated interval.

Channels, near-wellbore faults and failed bores from initial drilling can create pathways by which oil from one zone can enter the wellbore at a depth associated with a different zone. Production logging results in misallocation of oil in these situations, if only wellbore entry is considered. In contrast, geochemical techniques are able to distinguish production from the various zones, regardless of entry points.

Because the geochemical approach relies only on produced oil samples obtained at surface, there is no risk of sticking a tool in the well. The geochemical allocation approach can also be used to assess the contribution of multiple fields to commingled pipeline production streams. Advantages include the ability to allocate in the absence of flowmeter data, and the ability to identify problems with flowmeter data.

REFERENCES

McCaffrey, M. A., H. A. Legarre and S. J. Johnson, “Using biomarkers to improve heavy oil reservoir management: An example from the Cymric field, Kern County, California,” AAPG Bulletin, v. 80, 1996, pp. 904-919.

McCaffrey, M. A., D. H. Ohms., M. Werner, C. Stone, D. K. Baskin and B. A. Patterson, “Geochemical allocation of commingled oil production or commingled gas production,” Society of Petroleum Engineers Paper 144618, 2011, pp. 1-19.

ACKNOWLEDGEMENT

This paper was prepared, in part, from SPE 144618, presented at the SPE Western North American Regional Meeting (Anchorage, Alaska, USA, May 7–11, 2011). We thank BP Exploration Alaska Inc., Alta Mesa Services, LP, and Weatherford Laboratories Inc. for permission to publish this work.

|

AUTHORS

|

|

MARK MCCAFFREY is a Senior Technical Advisor at Weatherford Laboratories. He has 21 years of industry experience, including 11 as the founder and President of OilTracers LLC, a firm which was acquired by Weatherford in 2010. He has a BA in geology from Harvard University and a PhD in chemical oceanography from the Massachusetts Institute of Technology / Woods Hole Oceanographic Institution Join Program. |

|

| DANIELLE OHMS is currently Technology Lead for BP Exploration (Alaska) Inc. She has worked as a Production Engineer in Alaska for the last 23 years. She has a BS in petroleum engineering from the University of Texas, and an MS in environmental engineering from the University of Alaska, Anchorage. |

|

| CHRISTOPHER STONE is a Production Engineer with BP Exploration Alaska (Inc) since 2005. He has a BS in chemical engineering from the University of Minnesota – Duluth, and an MS in petroleum engineering from the University of Alaska – Fairbanks. |

|

| DAVID BASKIN is a Senior Petroleum Geochemist at Weatherford Laboratories. He received a BS degree in geology from San Jose State University and continued graduate studies at both California State University at Fullerton and California State University at Long Beach. He has over 37 years of industry experience at Chevron (ChevronTexaco) and OilTracers LLC. |

|

| BROOKS PATTERSON is a Senior Petroleum Geochemist at Weatherford Laboratories. He has a BA degree in earth science from California State University at Fullerton and an MS in geology from University of California at Riverside. He has over 35 years of industry experience at Chevron (ChevronTexaco) and OilTracers LLC. |

|

| DAVID REISDORF is a Senior Reservoir Engineer with Alta Mesa Services, LP. He has over 36 years of reservoir and production engineering experience in Oklahoma, Texas, Florida and Alaska. He received BS and MS degrees in chemical engineering from the University of Arizona. |

|

ARRIVING AT ALLOCATION ALGORITHMS

Wells discussed in this article involved “dead” oil samples—samples collected at the surface at ~1 atmosphere pressure—that were analyzed at Weatherford Laboratories using a gas chromatograph. GC peak data were processed to calculate the production allocation splits, using a proprietary geochemical production allocation software package. The allocation algorithms in that software are based on the following approach.

If there are no systematic sources of error, the relationship between a GC peak height “Y” (measured in the GC trace of a commingled oil) and the GC peak heights “X” of the corresponding peaks in the “m” end-members oils being commingled is given by a linear relationship of the form:

Production allocation is the process of determining the values of β.

In reality, there are multiple sources of error, including the following:

- Analytical error in measuring the height of each GC peak;

- Error associated with potential contamination of GC peaks; and

- Error associated with the non-ideality of the samples chosen as end members. For example, end member oils are often taken not from the same well as the commingled oil, but rather from nearby single-zone producing wells that may not be laterally continuous with the commingled well.

Because of the various sources of error, certain GC peaks will do a better job than others at allocating each zone’s contributions to a commingled oil. It is impossible to know, in advance, which GC peaks will do the best job of the potentially hundreds available in an oil allocation project.

The problem thus becomes one of linear regression. Specifically, given a set of samples containing a value for each independent variable and the corresponding value of the dependent variable, the β values must be computed in a relationship of the form:

Where, “eps” represents the error that is not captured by the linear relationship.

Linear regression can be used to converge upon a set of β values that minimizes the sum of the square of the errors. For example, as noted by McCaffrey, et al. (1996):

is a simple way to derive an estimate of the β vector. In numerous unpublished studies conducted between 2000 and 2010, we have found that significantly better estimates of the β vector can be derived by various optimization techniques that take advantage of the fact that there are far more GC peaks that can be measured in an oil (~1,000) than there are zones being comminlged. Those techniques are described in McCaffrey, et al. (2011).

|

|