KURT ABRAHAM, Executive Editor

On a cool, drizzly South Texas Sunday, U.S. Rep. Pete Olson (Republican–Texas) did what very few of his colleagues have done or will do—he actually went on a multiple-stop field visit to see and learn all that he could about today’s upstream oil and gas operating practices. This relatively rare event took place on Feb. 12, south and southwest of San Antonio in different portions of the Eagle Ford shale.

|

| U.S. Rep. Pete Olson (Rep.–Texas Dist. 22) |

|

There were two distinct halves to the congressman’s visit. The first half, hosted by Chesapeake Corp., included a briefing at the firm’s regional office and watching an active drilling site operated by the company. The second half, hosted by Swift Energy, featured a briefing, a stop at a producing wellsite and a visit to a second wellsite, where a multi-stage frac job was being prepared. Olson said that beyond improving his own personal knowledge, there were important reasons to take the trip.

“I’m on the House Energy Action Team (better known as HEAT), and I’ll be able to tell them what I’ve seen,” explained Olson. “We’re getting educated on energy issues and operations, so that we can go and educate other House members.” Swift Energy President Bruce Vincent elaborated on the congressman’s mission. “He wanted to learn the impact of these Eagle Ford operations on South Texas, economically and physically,” said Vincent. “He wanted to see how we’re operating in an environmentally responsible manner.”

Chesapeake drilling site. After an hour’s drive from San Antonio, the congressman’s tour group arrived at its first stop, Chesapeake’s regional office in Pearsall, Texas. There, the group attended a briefing on hydraulic fracturing. From that office, the entourage drove to the Chesapeake drilling site for an hour’s worth of observation of various functions. Due to some logistical constraints on Chesapeake’s end, World Oil was not able to go to the drilling site. However, we did catch up with the congressman later at Swift’s field office.

While we are not able to give a first-hand account of that portion of the tour, we do know that the congressman observed drilling operations from the top doghouse (Fig. 1), received instruction on directional drilling tools, and was shown the rig’s drilling mud tank, and filtration and pumping systems. In addition, we have Congressman Olson’s observations from the wellsite.

|

| Fig. 1. Congressman Pete Olson (white coat) gets some instruction on operations from rig personnel in the top doghouse of a Nomac Drilling, LLC, rig. Nomac is an affiliate of Chesapeake Oilfield Services, which is a subsidiary of Chesapeake Energy Corporation. Photo courtesy of Office of Rep. Pete Olson. |

|

“One of the things that jumped out at me is how fast and efficiently the contractors are able to drill wells now,” said Olson. “At the Chesapeake site, I watched them add three joints (90 ft) of drill pipe downhole in less than 15 minutes, at a depth of 4,500 ft.” The congressman said that this particular facet would be of great interest to one of his colleagues, who knows next to nothing about oil and gas operations. “One member of our HEAT team, who is from a western state, didn’t know how far down the drill pipe goes during drilling. She had no idea (although she does now).”

Another observation that Olson made from the Chesapeake site, as well as the Swift wells later, is how safety is emphasized in every part of the operation. In the wake of the Macondo accident offshore in the Gulf of Mexico two years ago, the congressman has been concerned that the public’s perception of how the industry handles safety does not match up with the reality. “I think there is some disconnect with the public on that subject,” said Olson. “But I can tell you that what I saw out there was safety, safety, safety. In every phase of the drilling process, safety is stressed. Everybody out there has got each other’s back. This is something that I will emphasize to my colleagues in the coming months.”

AWP field. From the Chesapeake site, the tour group headed out in mid-afternoon to Dilley, Texas, for a hand-off to Swift Energy Vice President of Operations Randy Bailey, who would escort the congressman for the balance of the day. After an hour’s drive from Dilley, the entourage arrived at Swift Energy’s AWP field office near Tilden, Texas. AWP field was discovered by Shell in 1983. In 1988, Swift acquired its first interest in AWP, and the firm eventually acquired Shell’s holdings there, as well. In 1988–1989, Swift began operating at AWP. The field originally focused on the Olmos formation, but it has since been expanded to the Eagle Ford shale. Today, there are more than 600 total wells, including more than 60 recent wells that have been completed with horizontal sections. The field is currently producing 60–70 MMcfgd and 10,000 to 12,000 bpd of oil and natural gas liquids on a gross basis.

At the AWP offices, the entourage viewed the company’s Drilling Operations Center (Fig. 2), where engineers can remotely monitor up to seven wellsites simultaneously. Congressman Olson was impressed with the firm’s ability to monitor drilling conditions at seven rigs remotely in real time. “There is some significant technology at work in that center, and most of my colleagues and the public aren’t aware of it,” said Olson. “When I looked at all the computer screens and read-outs, I thought of NASA and Mission Control, and I couldn’t help comparing those complex operations with the sophistication of the drilling center.”

|

| Fig. 2. Swift Energy V.P. for Production Randy Bailey (left) gestures while explaining the functions of his firm’s Drilling Operations Center to Congressman Pete Olson (right), while Swift field engineer John Mogk looks on. |

|

In addition to the drilling center, Olson’s group visited a geological room, where recent cuttings from new drilling are analyzed. From there, it was off to another safety briefing before visiting two field sites at AWP.

The first AWP field stop was at a centralized production site featuring a significant amount of surface equipment, including separators, dehydrators, a heater treater, produced water tanks, gathering lines, etc. At this site, AWP Field Superintendent Robbie Walters explained to Olson how water often flows into a well along with oil and gas. He explained how fluids are collected by surface equipment for separation into gas, oil, and water fractions for storage and distribution, and how produced water must be properly disposed. One of Walter’s staff also explained the operation of a “well control plate,” Fig. 3.

|

| Fig. 3. Swift’s Mark Valdez (right) explains to Rep. Pete Olson the operation of surface production equipment, as well as a well control plate. |

|

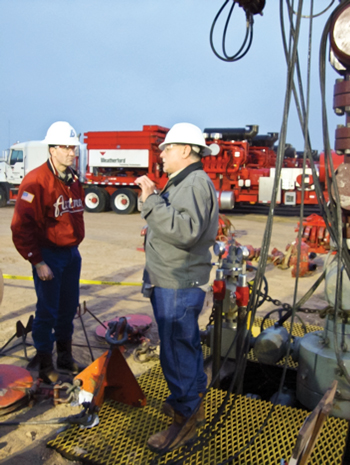

The second and final AWP site was a frac job being prepared at the SMR JV 3H well. Here, Olson and the group were briefed initially by Swift wellsite supervisor Chris Crawford about what they would see, as everyone walked around the wellsite. The congressman then visited with a number of Weatherford field hands, who would perform the frac job. Then Crawford took Olson’s group out to the frac stack, itself, to give them a thorough explanation (Fig. 4) of what would occur in this multi-stage frac. This was followed by a complete walk around the wellsite, as Crawford explained to the group what the roles of the various pieces of equipment would be, and the fact that fewer frac trucks are needed now than what were used in the earlier frac jobs, some years back.

|

| Fig. 4. Standing next to the frac stack, Swift Energy’s Chris Crawford, wellsite supervisor of the SMR JV 3H well, explains to Rep. Pete Olson (left) how the multi-stage frac job will be carried out. |

|

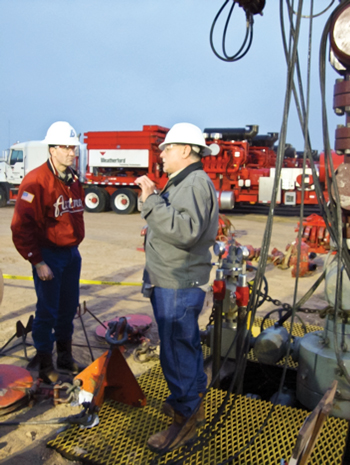

Olson was duly impressed with the sheer scale of the frac job (Fig. 5), the complexity of the field operations and the dedication of the people involved. “A lot of people in this country think that oil and gas is an old industry and low-tech,” said the congressman. “They couldn’t be more wrong. I am impressed with the skills of the people working these wells, and the amount of capital and assets involved. The expansion of U.S. drilling and production efforts, particularly in shale plays like the Eagle Ford, is enormous.”

|

| Fig. 5. On a cool, rainy, somewhat surreal Feb. 12 evening, Weatherford and Swift Energy personnel make preparations for a multi-stage frac job on the SMR JV 3H well in AWP field. |

|

After eight hours of touring wellsites in cold, often rainy conditions, Olson had an even greater appreciation for the positive effect that the U.S. E&P industry is having on the country’s economy, as well as for the work done by its personnel. “There is no way to overestimate the beneficial economic effects, especially as I’ve seen them here in South Texas,” said the congressman. “In one Eagle Ford county, alone, there has been a 3,000% increase in sales tax revenue, and there has been a 4,000% jump in property tax revenue. That’s what I call adding value.”

The congressman saved his most appreciative words for the operator and service company staff working out in the field, day after day. “I think the single most important impression that I have taken from these visits is the sheer dedication that these men and women have to our country,” reflected Olson. “They are out there doing their jobs in that rain and cold, on time and safely, because they really care about giving our nation energy.”

Olson’s field visits made him determined to spread the word about the contributions of the U.S. upstream sector. “The most important thing that I can do, is to stand up and fight for American energy, he said. “(President) Obama talked a good game in his State of the Union speech, but he doesn’t follow it up with positive action.”

Indeed, in the weeks following the field visits, Olson has made good on his commitment, lambasting Obama’s policies on several occasions. On Feb. 24, the congressman noted that Obama “took credit for increased domestic production that his administration has been fighting tooth-and-nail to overregulate.” And on March 1, Olson took issue with another presidential energy speech, stating that “the President’s comments reflect his policies: incoherent, unreliable, divisive and desperate. Standing up for a reliable, affordable source of energy is standing up for America, and the nine million jobs that come with it.”

|