IZUCHUKWU ARIWODO, ALI AL-BELOWI and RAMI BINNASSER, Saudi Aramco; ROBERT KUCHINSKI and IBRAHIM ZAINADDIN, Weatherford International Ltd.

Saudi Aramco’s EOR program employing 3⅞-in. sidetracks with high doglegs has necessitated the use of logging tools capable of accessing these small boreholes.

To meet its production goals, including enhanced recovery from mature fields, Saudi Aramco has been dedicated to the development, support and early adoption of recovery- and economy-enhancing, risk-reducing technologies, including horizontal and multilateral drilling, smart completions and completions utilizing passive inflow-control devices. To drain new areas of producing reservoirs more economically, the company has joined other operators in drilling small-diameter, short-radius, lateral re-entries with maximum reservoir contact, as opposed to new wellbores.

Historically, ultra-slimhole sidetracking has presented numerous drilling and completion challenges for operators. Sidetracking points have often been determined by the expected hole size of the final target zone, making it necessary to plan the well path backward from total depth to the sidetrack point of the mother bore. Traditional bottomhole assemblies are too large in diameter to provide the necessary flexibility for fast angle building. Stuck pipe has been common when drilling holes with diameters of 5 in. or less. Tubular and completion size restrictions also prohibited running ulta-slimhole smart completion systems.

These issues were addressed by advancements in ultra-slimhole drilling and completion technologies, which enabled wellbore diameters of 5 in. and smaller. These wells required less drilling fluid and chemicals as well as less expensive casing and completion materials, which led to more cost-effective and environmentally efficient operations. The development and successful application of ultra-slimhole drilling and completion technologies motivated development of complementary ultra-slimhole formation evaluation technologies.

EVOLVING ULTRA-SLIM LOGGING

Subsurface petrophysical and geological measurement devices have been used since 1927, when the first electrical well logs were generated. Since then, wireline-conveyed logging has become a key to enabling a better understanding of the subsurface for the petroleum, groundwater, mining and geotechnical industries. Applications drive measurements and range from simple resistivity, for groundwater, to sophisticated formation evaluation for oil and gas development.

Smaller-diameter logging tools have been used for quite some time in the petroleum industry as a part of cased-hole logging applications, but small-diameter, openhole logging was truly born in the mining industry. While logging tools for oil and gas development evolved to meet the demands of production conduits with diameters up to 36 in., depths of over 30,000 ft, and downhole temperatures and pressures of more than 160°C and 20,000 psi, respectively, mining-applied logging tools evolved primarily to gather information about the subsurface in slimmer, openhole wellbores and shallower wells. Additionally, mining logging tools were designed to be easily transported to remote locations with much smaller drilling footprints than those associated with oilfield operations.

Limitations in three key areas—borehole characterization, pressure and temperature capabilities, and range of measurement options—prevented ready transfer of mining logging technology to ultra-slimhole petroleum applications. The rapid, widespread acceptance of ultra-slimhole drilling in the 1980s created a gap in evaluating wells drilled using this method, and spawned new research into small-diameter logging technologies for the oil field.

The objective was to develop openhole logging tools that could provide accurate measurements in both ultra-small-diameter (less than 3 in.) and large-diameter (greater than 12¼ in.) holes; ability to operate at elevated borehole temperatures and pressures; a full range of common oilfield measurements; and ability to access difficult boreholes through the drill pipe. Additional objectives included short, rigid construction to help negotiate severe doglegs and minimize rathole drilling; low enough weight for single-person handling, remote location deployment and easier horizontal pushing with tractors or coiled tubing; and ability to operate with or without wireline.

RANGE OF MEASUREMENTS

Today’s small-diameter openhole logging tools make both basic and some specialized petrophysical measurements. Resistivity array induction tools measure formation resistivity and invasion profiles in freshwater and oil-based wellbore fluids as well as in air-filled boreholes. Enhanced processing techniques enable 6-in. vertical resolution. Dual laterolog tools measure formation resistivity in environments displaying a high contrast between total resistivity and mud resistivity (Rt/Rm). The tools generate individually optimized deep and shallow penetration curves that share a common 2-ft vertical resolution. Micro-resistivity tools can be configured as micro-log or micro-laterolog tools using interchangeable pads that can be adapted to specialized pipe-conveyed logging operations.

Weatherford International’s density-neutron porosity tools use a chemical source and highly sensitive detectors to derive dual neutron porosity. The tools are fully characterized for both air and mud in cased and open holes. A photo density tool measures formation bulk density and photoelectric effect using an articulated, skid-mounted chemical source and scintillation detectors to maintain contact with the formation in washed-out borehole sections. The skid plate profile is adapted to maximize contact with the formation, regardless of the size of the bit.

Spectral gamma ray sensors are used to measure and separate natural gamma radiation so as to determine the quantities of potassium, uranium and thorium in the formation.

The formation pressure tester uses a quartz gauge for highly accurate measurements and a “car jack”-type mechanism to extend the pad against the borehole wall to ensure an optimal seal, regardless of borehole rugosity, Fig. 1. Interchangeable pads and arms make the tool readily adaptable to hole sizes from 3 in. to 12¼ in. and keep the tool body in the center of the borehole to prevent differential sticking. By using conveyance techniques not possible with conventionally sized tools, pressure data can be acquired in difficult-to-log wells with little lost-in-hole risk.

|

|

Fig. 1. Weatherford’s Compact MFT formation pressure tester generates accurate formation fluid pressure measurements in borehole sizes from 3 in. to 12¼ in., with setting and closing time one-half to one-fourth of that experienced with conventional formation tester tools.

|

|

Sonic tools measure formation compressional slowness using a single-sided array of transmitters and receivers. Formation shear slowness is measurable by recording full waveforms. The tools are also adaptable to evaluate the cement bond in cased holes. Small-diameter memory cross-dipole tools combine monopole and cross-dipole acquisition capabilities. These tools can be deployed either with or without wireline, and because waveform data are recorded to internal memory, the tools are not constrained by wireline data transmission rates. As a result, larger volumes of acoustic data can be acquired, providing more insight into the anisotropic properties of the formation for geophysical, petrophysical and geomechanical applications.

Ultrasonic gas detectors are used to detect high-frequency acoustic energy associated with the flow of gas into the wellbore. Gas flow is confirmed by an associated drop in borehole temperature, measurable with a borehole temperature sub that is run in tandem with the gas detector.

Weatherford’s eight-arm, Compact Microimager (CMI) micro-resistivity imaging tool uses interchangeable pads to measure high-resolution formation images in water-based fluids in boreholes with diameters ranging from 3 in. to 13 in. while ensuring coverage similar to that of larger imaging tools. Tool diameter can be either 2.4 in. or 4.1 in. and can be deployed using a number of conveyance techniques not possible with conventionally sized tools, Fig. 2.

|

|

Fig. 2. A 2.4-in. CMI micro-resistivity imaging tool is shown in the open position exiting open-ended drill pipe.

|

|

The slim, short, lightweight design and lower power requirements of these tools expanded the number of ways that they could be conveyed into wellbores. Small diameters enable the tools to be run with greater efficiency and reduced risk in standard drill pipe and production tubing, in wells as small as 3 in. The short lengths allow the tools to navigate high doglegs, such as those in ultra-slim sidetracks. Their light weight makes the tools easier to push with well tractors and coiled tubing. In addition, running tools without wireline expands options to transmit power to enable the tools to log in less time, with better well control and a lower risk of equipment damage.

ULTRA-SLIM TOOLS AID IN TAPPING ATTIC OIL

After more than 70 years of production, Saudi Arabia’s giant Ghawar field is still a major oil and gas producer, in part due to Saudi Aramco’s implementation of new technologies to improve recovery. The company’s application of ultra-slim logging technology is helping, with 2.25-in. to 2.4-in. diameters that have been used to successfully log 3⅞-in. sidetracks with high doglegs, which would have been previously impossible. They have also been used to evaluate newly drilled wells with potential well control issues.

Similarly, old wells that were originally completed without the benefit of full formation evaluation can now benefit from a suite of wireline logs. Currently, Saudi Aramco is using 2.25-in. to 2.4-in. tools to provide traditional wireline logs, namely density, neutron, resistivity, sonic and gamma ray. Ultra-slim resistivity imaging aids in identifying borehole breakout and fracture features that could affect the well’s productivity. Meanwhile, ultra-slimhole pressure testing has been used to generate a pressure gradient, determine oil mobility and define oil-water contacts.

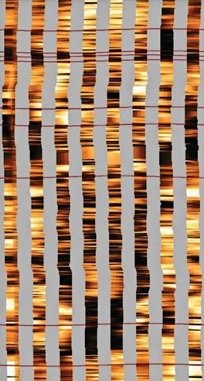

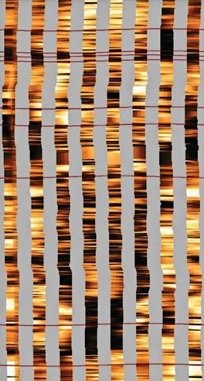

Weatherford’s ultra-slimhole triple-combo suite, which consisted of gamma ray, induction resistivity, photo density and dual-neutron tools, was conveyed on the end of drill pipe in memory mode to a target within a short-radius horizontal sidetrack that had been drilled to drain attic oil from the main reservoir. Earlier, a window had been cut from the 7-in. liner, and the build section drilled to the target reservoir, which was then cased with a 4½-in. liner. The lateral was subsequently drilled with a 3⅞-in. ultra-slimhole assembly. The triple-combo suite was then used to successfully log across the 3⅞-in. horizontal section. Additionally, a microresistivity log was run to evaluate the porosity in the reservoir and place the completion for maximum productivity, Fig. 3.

|

|

Fig. 3. A formation resistivity image from a small-diameter tool placed in a sidetrack designed to drain attic oil from a reservoir in Ghawar field.

|

|

The vertical producer well in Fig. 4 was initially completed without logging because pressure control problems at the time of drilling prevented openhole logs from being run. The service company subsequently acquired a full set of real-time openhole logs in a rigless operation by conveying an ultra-slim triple-combo suite on wireline through the production tubing in the well’s barefoot section.

|

|

Fig. 4. A triple-combo well log from a vertical well logged with wireline-conveyed, ultra-slimhole tools through production tubing in a rigless operation.

|

|

To determine the reservoir pressure regime in a 3⅞-in. vertical evaluation well, Saudi Aramco ran Weatherford’s MFT formation pressure tester. With an outside diameter of 2.4 in., the MFT is the smallest reservoir pressure measuring device currently in the industry. The pressure scatter indicated a tight reservoir with low mobility. The pressure readings obtained with the ultra-slim tool agreed with a subsequent barefoot drillstem test, Fig. 5.

|

|

Fig. 5. A pressure drawdown profile from an ultra-slimhole formation pressure test agreed with a barefoot drillstem test that followed.

|

|

Ultra-slimhole drilling has proven to be an effective and economical way for Saudi Aramco to access mature reservoirs in Ghawar field. The case studies described above show how the operator is using ultra-slimhole logging tools to evaluate these reservoirs to make better-informed decisions on the type and deployment of completions.

ACKNOWLEDGEMENT

This article was prepared in part from SPEKSA 0034 presented at the 2010 SPE/DGS Annual Technical Symposium and Exhibition held in Al-Khobar, Saudi Arabia, April 4–7, 2010.

THE AUTHORS

|

| IZUCHUKWU ARIWODO works in Saudi Aramco’s Reservoir Description division as a Gas Development Petrophysicist. He started his career over 18 years ago as a Petroleum Engineer with Shell E&P. Mr. Ariwodo holds a bachelor’s degree in mechanical engineering and an MS degree in industrial engineering. |

| |

| ALI AL-BELOWI is the Supervisor for Saudi Aramco’s North Uthmaniyah unit. He joined Saudi Aramco in August 1989 as a petroleum engineer after receiving his BS degree in petroleum engineering from King Saud University in Riyadh. |

| |

| RAMI BINNASSER is a Lead Petrophysicist for Saudi Aramco and Supervisor of the Special Studies unit in the Reservoir Description and Simulation department. He previously worked as a Wireline Logging Engineer with Schlumberger and Baker Atlas. Mr. Binnasser holds a BS degree in engineering from King Fahd University of Petroleum and Minerals in Dhahran, Saudi Arabia. |

| |

| ROBERT KUCHINSKI is the Weatherford Wireline Business Development Manager for the Middle East and North Africa, and has been involved in the acquisition of subsurface data since 1976. In 1986, he joined Reeves Wireline, where he played a key role in the development of the company’s Compact technology, which was acquired by Weatherford in 2005. Mr. Kuchinski holds a BS degree in geology and a certificate in business management. |

| |

| IBRAHIM ZAINADDIN is the Weatherford Wireline Operation Manager for Saudi Arabia, Bahrain and Kuwait, with over 14 years of engineering experience. He played a key role in the introduction of the Compact technology in Saudi Arabia. Mr. Zainaddin holds a BS degree in applied electrical engineering from King Fahd University of Petroleum and Minerals. |

|