Innovative thinkers

Paul Koomey:

Steam pumps, nuclear-BOP controls and a few crawfish boils in between

|

Paul Koomey

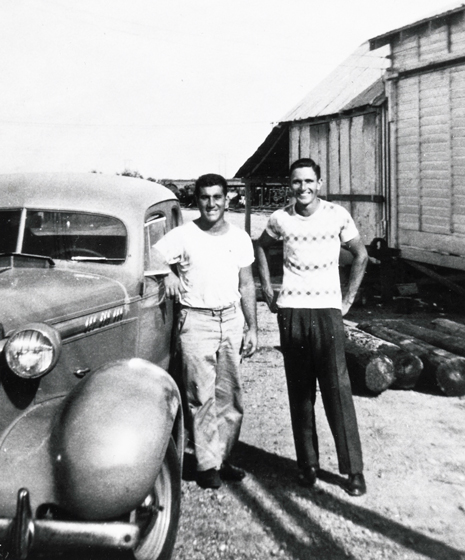

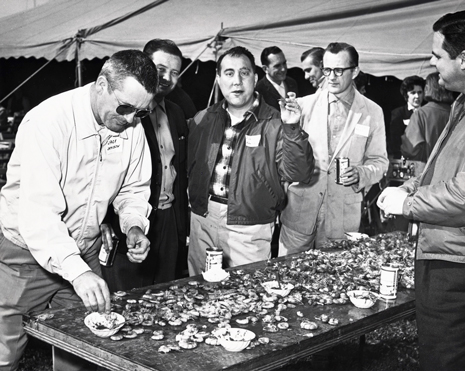

You will be hard-pressed to find a Composite Catalog from the late 1950s to and on that does not contain the Koomey name. Paul Koomey, founder of Koomey Inc. and well control inventor has spent over five decades developing technology that has made him a household name in the oil business. From his days of showing test equipment out of the back of his Chevy truck, to pioneering the world’s first nuclear-powered subsea generator, Koomey’s namesake – as well as his infamous crawfish boil parties - have become a legend in their own right. Koomey began his career as a roustabout while attending Texas A&M University and then the University of Houston on an athletic scholarship. After working on barge-mounted steam rigs, he joined Stewart & Stevenson’s Alemite division as a sales representative with a $250 advance. From the beginning, he knew he wasn’t cut out to be a salesman. “I saw what equipment was out there and knew that I could make improvements,” Koomey said. In 1951, Koomey designed a mock-up for a blowout preventer (BOP) control system with air-modified pumps and loaded a test unit into his Chevy to show to Shaffer Oil Tools. Alemite did not want its name on the device, so his boss, Ross Stewart, told Koomey to use his own name instead. After demonstrating the unit’s speed and reliability in activating the BOP’s ram system, Koomey received his first order. His next orders came from Magnolia Petroleum, when he demonstrated how his control system could be used for pressure testing the entire BOP stack. In late 1957, Koomey began to notice that the current BOP controls on the market, including his, needed to be more reliable. Koomey’s units provided both electric and air-powered hydraulic pumps to charge the accumulators. As annular BOPs increased in size, more pressure would be needed to close the BOP, yet not too much pressure as to exceed the maximum closing pressure that could damage the annular element. The actuator required the development of a valve that would allow hydraulic fluid to be stored at 3,000 psi in the accumulator, then reduced to 1,500 psi for actual closing. The systems at the time were designed to shut the annular preventer first, then activate the rams. The accumulator on the system, which stored the hydraulic power, would have to be large enough to close the well head tightly. With the introduction of a KR valve to the unit, Koomey’s control system was the first on the market to handle the higher pressures that the market required. Koomey took his new 3,000-psi control design to Shell, who at the time was looking for the first time, to convert a submersible rig into a semisubmersible at its Blue Water I project in the Gulf of Mexico. Shell selected Koomey’s design. “It was the 3,000-psi system that pushed us worldwide,” Koomey said. ““That was a real progress as far as sales and leadership was concerned in the control business.” In 1959, Koomey realized he needed to advance his inventions and developed a 27 1/2-ft-long retrievable BOP control subsea pod. The pod, which had mechanical and hydraulic locks and was controlled by coded acoustic signals, which eliminated the need for surface-mounted umbilical lines. After Koomey shortened the pod to 10 ft and added a central choke-and-kill line, Shell installed the unit offshore the UK. By 1970 Koomey soon held an 85% market share of subsea BOP control systems worldwide and 100% of BOP controls in the Soviet Union and China. After working with Exxon Production Research on pilot valves and an electrohydraulic system, Koomey began to look at subsea nuclear generators. His unit, which used the isotope Strontium-90, could produce 5–10 Watts for a minimum of 100 years. While the unit was successfully tested, it was never commercially produced. “A nuclear power source subsea would eliminate a whole lot of electric lines,” said Koomey. After his division was sold to NL Industries in 1978, he founded Koomey Inc. “I decided to start from scratch,” Koomey said. While initial sales in 1979 amounted to around $6 million, the company reached sales of $70 million, with $100 milllion in backlogs, by the end of 1981. Once retired, Koomey and his good friend George Savage spent their time developing a ram position indicator and a drill string identification system. In 1957, what began as a small annual crawfish boil for Koomey employees and clients, founded by Koomey’s colleague Joe LeMoine, has grown into an international tradition as an annual event at the University of Houston, attended by thousands of people each year, including Koomey himself, the Sunday before the Offshore Technology Conference in Houston. “Most companies deal with people,” Koomey said. “Great things take a team. If you get together people who love what they do, and build personal relationships with your customers, you can’t lose.”

|

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)