NELL LUKOSAVICH, Senior Editor

Given the impact of the Macondo disaster on the offshore oil and gas industry, a special emphasis is being placed at this year’s Offshore Technology Conference on the industry response and operational changes following the spill last year. OTC 2011, which is themed “Diversity in energy, people and resources,” will feature more than 300 technical presentations, panel sessions, discussion forums and special events relating to current challenges and the future direction of the offshore oil and gas industry. “There are sessions discussing some of the most challenging technical issues facing the industry,” said Stephen Graham, Society of Petroleum Engineers managing director for the Americas. “The OTC 2011 technical program is one of the best programs ever produced.”

This year’s show will introduce several new events, discussion topics and a new outdoor exhibition space, making it the largest OTC in almost three decades in terms of square footage. New topics in the technical program include enhanced oil recovery (EOR), shale gas developments and marine archaeology. The shale session “relates to how shale gas development is affecting the global market for natural gas, especially how it is changing the dynamic of the development of LNG,” Graham said. “Marine archeology is an area of interest because it affects offshore operations. The US government protects historic areas, even underwater, and the impact of the 2001 UNESCO Convention adopted by 36 countries, when paired with local regulations, is at present an unstudied and largely unknown issue for the offshore energy industry.”

OTC 2011 will be held May 2–5 at the Reliant Park complex in Houston, Texas. Last year’s show brought in 72,900 people from 120 different countries—the second highest level of attendance since 1982. More than 2,400 exhibiting companies from 40 countries filled the exhibition area’s 568,000 sq ft. In 2011, the show will have 587,000 sq ft of exhibit space—the largest in 29 years.

.jpg) |

|

Fig. 1. OTC 2010 exhibition hall. Image courtesy of Barchfeld Photography.

|

|

What’s new this year. For OTC 2011, the highest-profile topic will be the impact of the Macondo oil spill on oil and gas drilling in the deepwater Gulf of Mexico. Amid a new era of rapidly changing government regulation and oversight, several panels of experts and high-level government officials will address issues related to risk, drilling safety, energy development and spill response for future oil and gas projects.

The 2011 conference will host the inaugural OTC Dinner, which will be held at the George R. Brown Convention Center on Sunday, May 1, from 6 to 10:30 p.m. The dinner will recognize the recipients of the OTC Distinguished Achievement Awards, which in previous years were presented at one of the show’s daily luncheons. The dinner raises funds to benefit the Gulf of Mexico Foundation, a non-profit organization dedicated to promoting the continued health and productivity of the Gulf through education, public awareness, research and leadership programs.

The dinner is planned to become an annual event. “The Annual OTC Dinner was added to the OTC events schedule to create a signature event that highlights OTC’s Distinguished Achievement Awards, enables the industry to give back by providing financial support for a community charity, and offers an opportunity for OTC participants to meet each other socially to kick off OTC week,” said Susan Cunningham, this year’s OTC chairperson.

The 2011 show will add 29,000 sq ft of outdoor exhibition space—for a total of 69,000 sq ft outdoors—through the introduction of an expanded showcase corridor called the OTC Parkway. Designed to increase traffic to the Reliant Arena exhibits from the main exhibition space in Reliant Center, the parkway will feature new food pavilions offering more variety and expanded seating, exhibitor lounges and small, covered 10 ft 3 10 ft outdoor booths, which will enable smaller companies to exhibit. Previously, the smallest outdoor booth size was 10 ft 3 20 ft.

| OTC 2011 technical sessions |

|

|

Awards presentation. Cort Cooper, a meteorology and oceanographic specialist at Chevron Energy Technology Company, will receive the 2011 OTC Distinguished Achievement Award for Individuals during the OTC Dinner. Cooper will be given the award for his pioneering work in metocean research and his leadership of joint industry efforts to address oceanographic challenges. His work includes research that identified a link between hurricane severity and the Loop Current in the Gulf of Mexico, investigated the causes for recent severe hurricanes, including possible impacts of global warming, and assessed metocean conditions during Hurricane Ivan.

Also at the dinner, BP Norway will receive the Distinguished Achievement Award for Companies, Organizations and Institutions. The company is being recognized for its Life of Field reservoir surveillance project, which demonstrated the practicality of implementing an entirely new method of seismic surveillance in producing hydrocarbon reservoirs. The project’s permanent installation of seismic cables, covering 45 sq km of Valhall field in the North Sea, allows for cost-effective repeat seismic surveys, and the system provides 4D data with unique repeatability compared to standard streamer data.

A Special Citation Award will be presented to ExxonMobil Development Company for its development and implementation of the “Design One, Build Multiple” philosophy to deliver major deepwater projects in Angola’s Block 15. The strategy resulted in the Kizomba C Mondo FPSO being completed and installed in a record 23 months from project approval to first oil.

In 2009, the awards presentation also included a Safety Award for Excellence, or SAFE Award, presented by the US Minerals Management Service (now the Bureau of Ocean Energy Management, Regulation and Enforcement). The short-lived, HSE-focused award was planned for 2010 but canceled in the wake of the Macondo spill, and OTC officials said there are no plans at this time for BOEMRE to present a similar award at future conferences.

| OTC 2011 topical breakfasts, luncheons and industry sessions |

|

|

Next Wave program. The Next Wave program, designed for upstream professionals under age 35 and companies interested in recruiting them, will take place on Monday, May 2, from 8:15 a.m. to 2:30 p.m. The 2011 event will focus on helping young professionals position themselves within the entire value chain of the oil and gas industry. Gerald Schotman, chief technology officer for Shell, will deliver this year’s keynote address.

University R&D Showcase. This year, OTC will provide seven participating universities a forum in which to share with attendees their current and planned R&D projects of relevance to the offshore industry. The University R&D Showcase will take place the first three days of the conference in the Level 2 foyer area of Reliant Center.

Projects being presented include vibration-based monitoring and inspection of deepwater risers (Rice University), fiber-containing sweeps fluid for ultra-deepwater drilling applications (University of Oklahoma), early stage detection of hydrate and asphaltene formation (Texas Tech University) and an innovative testing approach to marine current turbines and wave energy converters (University of Strathclyde).

.jpg) |

|

Fig. 1. OTC 2010 exhibition hall. Image courtesy of Barchfeld Photography.

|

|

Technical program. More than 300 papers will be presented during the show’s technical sessions. Program highlights include:

• Deployment of subsea equipment

• Economic and technical drivers to gas commercialization

• Ocean mining

• Strategies for fighting hydrates

• Hybrid riser systems

• West Africa geohazards

• Offshore carbon sequestration

• Advances in computational fluid dynamics (CFD) simulation

• Well testing and reservoir evaluation concepts.

New topics introduced at this year’s show include enhanced oil recovery, marine archaeology, deployment of subsea equipment, welding and shale gas developments.

SPOTLIGHT ON NEW TECHNOLOGY

Now in its eighth year, this OTC program will recognize 15 technologies representing 13 companies: Baker Hughes, Canrig Drilling Technology, Halliburton, MyCelx Technologies Corp., National Oilwell Varco, PG Pump Solutions, Reelwell AS, SBM Offshore, Schilling Robotics, Schlumberger, Techni, Twin Filter BV and Weatherford International.

Winners are selected on five criteria. First, the technology must be new—i.e., less than two years old, dating from the first time it was introduced to the marketplace or was announced or advertised in a conference, press release or trade journal. If previously advertised at OTC, it must not have been displayed for more than one conference. Second, the technology must be innovative, original and groundbreaking for the offshore E&P industry. For example, an improvement in efficiency of an existing motor would not be considered unless it had the potential to change the way in which the motor is used in the industry. Third, the item must have been proven either through full-scale application or successful prototype testing. Fourth, the technology must have broad interest and appeal for the industry. Lastly, the technology must make a significant impact, providing sizeable benefits beyond existing technologies. Environmental impact is an important judging criterion.

The awards will be presented at a special ceremony in the Reliant Center Lobby B Rotunda at 4 p.m. on Monday, May 1.

1) Ball-and-pocket design to grip casing

Canrig received an award for its SureGrip casing running tool. The tool’s ball-and-pocket gripping technology engages casing using spherical balls in tapered pockets to replace die slips, which minimizes handling impact, leaving the casing in its most robust condition. Accomplished by more evenly distributing load to hundreds of stainless steel balls, the tool minimizes damage to casing and overcomes technical and load limits of traditional die slips. Sharp indents from die teeth are eliminated as well, reducing potential casing failure risks later in wellbore life. Convenient plug-and-play options for a range of casing sizes eliminate the need for multiple tools.

.jpg)

2) Hybrid bit design for interbedded formations

Baker Hughes received an award for its Kymera hybrid drilling technology, which offers a fusion of roller-cone and PDC bit design. With the rock-crushing strength and stability of roller cones and the cutting superiority and continuous shearing action of diamond bits, the hybrid bit survives highly interbedded formations with performance consistency and excellent toolface control. Compared with roller-cone bits, Kymera can increase penetration rate and lower WOB with less bit bounce. Compared with PDCs, there’s significantly improved durability in interbedded formations, less stick-slip, lower and more consistent drilling torque, and better stability and directional control.

3) Hole-conformant sand control 3) Hole-conformant sand control

Baker Hughes received an award for its GeoForm sand management system. Outfitted with patented Morphic shape memory polymer (SMP) materials on the outside of the base pipe, the sand system reliably conforms to the borehole in an openhole environment—radically reducing complexity versus traditional gravel pack systems while improving efficiency. It also reduces rig time and mitigates workover risk associated with conventional techniques by decreasing the chance of plugging or sand control loss caused by production cycles and reservoir or borehole compaction. The system requires a smaller installation footprint than traditional sand control methods and covers a wide range of sand grains.

.jpg) 4) Water recycling at the wellsite 4) Water recycling at the wellsite

Halliburton received an award for its CleanWave water treatment process, a service of the company’s Baroid Industrial Drilling Products line. The service features a mobile electrocoagulation component that uses electricity to treat flowback and produced water at rates of up to 26,000 bpd while using minimal power. The system destabilizes and coagulates the suspended colloidal matter in water. When contaminated water passes through the electrocoagulation cells, the anodic process releases positively charged ions, which bind onto the negatively charged colloidal particles in water resulting in coagulation. At the same time, gas bubbles produced at the cathode attach to the coagulated matter, causing it to float to the surface where it is removed by a surface skimmer. Heavier coagulants sink to the bottom, leaving clear water, suitable for use in drilling, frac fluid and other production operations. This minimizes freshwater consumption and the costs associated with procurement and disposal.

.jpg) 5) Multipole sonic while drilling 5) Multipole sonic while drilling

Schlumberger received an award for its SonicScope 475 multipole sonic-while-drilling service. This new LWD tool provides multipole measurements to consistently and reliably deliver compressional and shear data in diverse environments. A dedicated mode for acquiring Stoneley waveforms while drilling ensures high-quality data before washouts can develop. Compressional and shear data, with the Stoneley wave acquisition, enable the assessment of rock mechanics and characterization of fractures. This is especially important in the North American shale plays for designing complex completions to optimize future production. In addition, a while-tripping mode provides multipass analysis and top-of-cement evaluation.

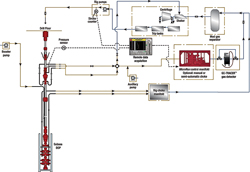

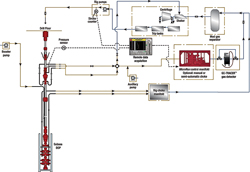

6) Deepwater closed-loop drilling

Weatherford received an award for its deepwater closed-loop system, which leverages proprietary algorithms to detect minute influxes or losses and provides real-time output so decisions are based on actual surface data, rather than predictive models. With applications ranging from routine wellbore monitoring to advanced managed pressure drilling techniques, the system’s below-tension-ring rotating control device allows the operator to fully enclose the wellbore and drilling fluids as a closed loop. The system enhances drilling efficiency, reduces costs and ultimately makes previously undrillable wells drillable.

7) High-voltage swivel for FPSOs 7) High-voltage swivel for FPSOs

SBM Offshore received an award for its high-voltage electrical AC (HV AC) swivel for turret-moored FPSOs and floating power generation units. The HV AC swivel allows offshore producers to transfer high-voltage electric power from shore to FPSOs (thereby reducing CO2 emissions) or from FPSOs to subsea equipment (leading to savings).

.jpg) 8) Heavy-duty multipurpose ROV 8) Heavy-duty multipurpose ROV

Schilling Robotics and FMC Technologies received an award for their heavy-duty work-class ROV system, which provides flexibility for achieving high performance across all key subsea markets including inspection, repair and maintenance (IMR), drill support, and medium-duty construction market applications. This compact system, designed for accommodating the specific needs of the IMR and drill support markets, is optimized for installation onboard drilling rigs and ROV support vessels, where available deck space is limited. The ROV features Schilling’s unique power management system and advanced automatic piloting modes that deliver superior operational stability and precise control. FMC Technologies owns a 45% share of Schilling Robotics.

.jpg) 9) Chemical affinity-based water treatment 9) Chemical affinity-based water treatment

MyCelx Technologies received an award for produced water treatment technology, which employs advanced chemical affinity-based separation equipment for the removal of low-level hydrocarbons and water soluble organics (WSO) from produced water. A patented molecule in the filter media coagulates oils and semi-volatile organics into a water-repellant mass, enabling efficient removal from the water stream. Units range in size from 1,000 bpd to 250,000 bpd and can be either stand-alone or retrofitted into any treatment train to ensure oil-in-water discharge of 10 ppm or less. The technology is currently used by onshore operators Anadarko, EnCana, Williams, Hess and the Canadian Natural Resources, and it was recently selected for Chevron’s Jack/St.Malo project in the Gulf of Mexico.

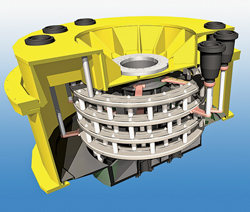

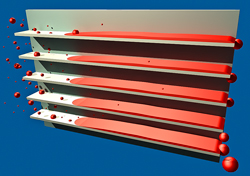

10) Dynamic centrifugal coalescer 10) Dynamic centrifugal coalescer

Twin Filter and CoalesSense received an award for their non-plugging dynamic centrifugal coalescer, which improves the performance of oil/water separators. The system increases the size of oil droplets from a few microns to as large as 200 microns, allowing traditional separation devices to remove the oil from the water at a much higher efficiency than they would working along. The device uses a combination of centrifugal forces and coalescing effect. An element consisting of thousands of tubes (of pore sizes 0.4 to 1.4 mm) is brought into rotation. The multiphase produced liquid passes through the core, where the centrifugal forces cause the droplets of the discontinuous phase to coalesce on the walls of the tubes. The combination of Stoke’s law and centrifugal forces allows droplets smaller than 1 micron to be coalesced with a much larger clearance than in traditional coalescers, greatly reducing plugging and fouling.

11) Multi-application pump system 11) Multi-application pump system

PG Pump Solutions and Techni received an award for their PG MAPS (Multi Application Pump Solution), a compact, lightweight and cost-effective pumping system applicable for several subsea and topside applications. The design combines a software-controlled linear actuating system and a permanent magnet motor from Techni with established topside pump head technology from Feluwa Pumpen. The combination of compact design, high capacity and high pressure makes this self-priming pump system extremely robust and well-suited for difficult applications. Typical subsea applications would include mud and drill cuttings handling, tophole drilling and liquid boosting, including heavy oil. The pump is small enough to be transported by truck and can be part of the standard equipment onboard supply vessels or platforms.

.jpg) 12) Petrophysical measurement 12) Petrophysical measurement

Schlumberger received an award for its Dielectric Scanner multi-frequency dielectric dispersion service. The scanner offers new petrophysical measurements for enhanced hydrocarbon saturation computation and is the first in the industry to accurately quantify residual hydrocarbon volume, Archie’s exponents and formation cation exchange capacity. Used in conjunction with traditional logging measurements, the scanner is able to determine residual oil saturation in carbonate reservoirs, hydrocarbon volume in low-resistivity or low-contrast shaly and laminated sand formations, and hydrocarbon volume and mobility in heavy oil reservoirs.

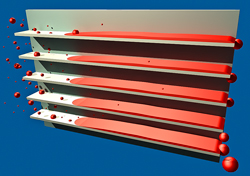

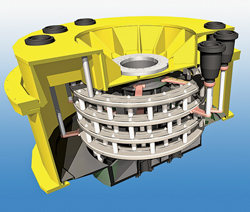

.jpg) 13) Heavy-over-light mud system 13) Heavy-over-light mud system

Reelwell received an award for its multi-gradient drilling system, which employs a fluid partition device to allow use of two or more fluid densities in the wellbore while drilling. The system employs a high-density passive fluid in the wellbore annulus above the bottomhole assembly and a lighter active circulating fluid that enables managed pressure drilling operations with zero surface pressure in the well annulus. Benefits include the ability to drill longer openhole sections, which reduces numbers of casing strings, along with the increased horizontal reach and reduced well cost. Additionally, the presence of higher-density kill mud in the well annulus at all times reduces the risk of blowout, even when performing advanced drilling operations.

.jpg) 14) Cryogenic hose for LNG 14) Cryogenic hose for LNG

SBM Offshore received an award for its Cryogenic Offshore Offloading and Loading (COOL) hose, which the company calls the world’s first flexible cryogenic floating hose for the offshore transfer of LNG. The product features a hose-in-hose structure with an inner composite hose and a traditional (Oil Companies International Marine Forum-compliant) marine hose as the outer protective body for floating applications. The hose allows offshore LNG producers to reliably and safely offload LNG in tandem from an FLNG liquefaction vessel to an LNG carrier.

.jpg) 15) Low-force casing shear rams 15) Low-force casing shear rams

National Oilwell Varco received an award for its ShearMax low-force casing shear ram system, which reduces the pressure required to shear heavy tubulars. New razor-sharp blades are able to cut through solid-steel pipe more quickly and efficiently than traditional blades. They slice through 2-in. drill pipe in less than 30 seconds and easily shear tool joints up to XT-69 without exceeding the operator’s safe working design envelope, making the system particularly well-suited as a deepwater safety solution. The technology’s reduced ram force allows the use of lighter support equipment. The ram system is currently contained inside NOV’s line of NXT BOP stacks, which offer a 5,000 psi, 22-in. operator. The company plans to expand the shear ram line to be housed in other BOP models in the near future.

|

.jpg)

.jpg)

.jpg)

3) Hole-conformant sand control

3) Hole-conformant sand control.jpg) 4) Water recycling at the wellsite

4) Water recycling at the wellsite.jpg) 5) Multipole sonic while drilling

5) Multipole sonic while drilling

7) High-voltage swivel for FPSOs

7) High-voltage swivel for FPSOs.jpg) 8) Heavy-duty multipurpose ROV

8) Heavy-duty multipurpose ROV.jpg) 9) Chemical affinity-based water treatment

9) Chemical affinity-based water treatment 10) Dynamic centrifugal coalescer

10) Dynamic centrifugal coalescer 11) Multi-application pump system

11) Multi-application pump system.jpg) 12) Petrophysical measurement

12) Petrophysical measurement.jpg) 13) Heavy-over-light mud system

13) Heavy-over-light mud system.jpg) 14) Cryogenic hose for LNG

14) Cryogenic hose for LNG.jpg) 15) Low-force casing shear rams

15) Low-force casing shear rams