|

Vol. 230 No. 10 |

Welding power source

ESAB Welding & Cutting Products introduced the CaddyTig 2200i AC/DC power source, designed to produce high-quality Tungten Inert Gas (TIG) welds and shielded metal arc (stick) welds in a variety of materials. This fifth-generation caddy machine features advanced inverter technology to deliver welding quality and performance in a compact design, with an impact-resistant polymer and aluminum casing. The unit offers control panels that present all welding parameters in a simple layout. A two-program function allows pre-programing and program changes during welding. CaddyTig offers a pulse-TIG feature for greater control of heat input and the weld pool, and a micro-pulse feature that minimizes the heat-affected area, particularly with thin metals. Other features include hot-start and arc-force settings. The unit also supplies AC welding capability with high arc stability. Its QWave feature provides low noise, and balance control optimizes the weld pool. Also included are electrode preheating to facilitate starts and extend electrode life, large cable connectors for high durability and large heat sinks for cooler running and longer life.

Cased-hole services tractor Schlumberger announced release of its TuffTRAC cased-hole services tractor. The new tractor is the industry’s shortest, and is the only one with full reverse and active traction-control capabilities. The system delivers over 40% greater efficiency compared with conventional tractors, resulting in more pushing power downhole. The reversing capability reduces fishing risk, and its modular design makes it easy to deploy in short rig-up situations. It is engineered to withstand the shock of a perforating gun, and can convey any other cased-hole service. The tractor runs on multiconductor wireline cables. The 31/8-in.-diameter tool has a pushing capacity of 300 lb per drive section, and a maximum string of six drive sections can be deployed in tandem for 1,800 lb of total pushing power. Active traction control provides the ability to monitor and change the pressure on each drive wheel to optimize traction in either direction. Capable of operation to 350°F and 20,000 psi, the system’s power pack can operate without cool-down periods. The tractor includes a built-in tension sub, electrical release sub, casing collar locator, addressable tractor perforating safety switch and shock absorber.

Wireless controlled safety valve

Expro announced the successful qualification and field trial of the FlowCAT retrofit wireless safety valve. The valve has recently completed a six-month trial in a gas well located onshore southern Italy. This marks the first use of the company’s Cableless Telemetry System (CaTS) in a flow-control application. CaTS is a new development in reservoir monitoring and control that allows information to be transmitted in real time to and from downhole instruments without the use of cables. Its two-way transmission capability enables the remote control of downhole instrumentation. FlowCAT is a fail-safe closed safety valve that can be installed in a well’s existing safety valve nipple profile, or by using an alternative suspension mechanism, and is controlled from surface using the electromagnetic wireless telemetry technology. During the trial, the 4½-in. valve was deployed into a well using standard slickline intervention methods and, over the course of the six months, was cycled and inflow tested regularly during both production and injection. The valve performed reliably and consistently throughout the test, with no false closure events observed.

Torque management system

Torque-tool specialist Norbar has introduced a new torque measurement, calibration, data archiving and management system. Called T-Box, it is powered by the company’s Torque Data Management System (TDMS) software. The compact device incorporates a broad range of torque-related capabilities. The system calibrates torque wrenches, stall tools, pulse tools, hydraulic torque wrenches and clutch tools. It performs detailed analysis of torque tool performance and joint characteristics, and the software prompts the return of tools at their required re-calibration interval. Setup is accomplished through intuitive touch-screen prompts. Up to four “smart” transducers, including those with an angle capability, may be connected to the device. Two USB ports, one RS232 serial port and an ancillary connection present a choice of interfaces. The system includes either pre-loaded tool templates or an integral tool template creator for non-Norbar tools, and is equipped with a large internal memory capacity.

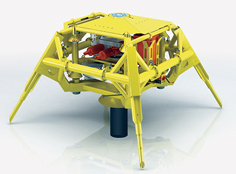

Shallow-water subsea tree

GE Oil & Gas has launched the new VetcoGray S-Series SVXT subsea tree. The S-Series SVXT subsea tree merges horizontal and vertical tree technology, reducing weight by 20%, decreasing height, and also delivering essential functionality in a pre-engineered, pre-configured modular design. Low-cost installation of the tree is achieved through a design that enables deployment using standard offshore jackup drilling rigs without the need for major modifications. New design features include a smaller tree and fisher-friendly wellhead protection structures, as well as a barrier approach that removes the need for a separate tree cap. The system comes with a SemStar5-powered ModPod as the standard control system.

Flange refacing tool

Hydratight has introduced a refacing tool for hard-to-reach pipe flanges. The light and portable QuickFace is a hand-powered tool with the performance of larger air-powered and electrically powered tools. It is operated by one man, and can be used anywhere a technician can physically reach. The QuickFace weighs 15 lb, and in its storage case with interchangeable collets and lead screws it weighs only 33 lb, but it can reface flange surfaces on pipes from 1 in. to 4 in. using standard half-inch cutting tools. Interchangeable lead screws make it suitable for resurfacing damaged raised-face and lens-ring joint flanges to the varying standards of finish required of standard and compact flange designs. For the operation, the tool body is inserted in the pipe end, centering itself with adjustable collets and clamps to provide true concentric accuracy. The tool arm is rotated by hand, a worm-gear mechanism providing a spiral “gramophone” finish. The tool can be adjusted with a calibrated slide to define cut depth and the correct finish.

Thread-engineering software

Gagemaker LP has released new thread-engineering software for API tapered threads, TDWIN Taper. The software provides critical dimensions and drawings for downhole tubular connectors based on current industry standards. All necessary details to machine, inspect and document tubular connection threads are in one source. The user can access information for both preferred and non-preferred rotary shouldered connections, tubing and casing connections, and any combination of crossover. Several options for viewing drawings, reviewing inspection gage information, or for setting up inspection reports are available. The software delivers printable drawings suitable for manufacturing, following ASME Y14.100 standards for industry compatibility. The program is available in single-user and server versions.

Space-saving shale shaker

MI Swaco has introduced the new MD-3 shale shaker. The small footprint of the MD-3 matches the MI Swaco BEM-650 shaker, simplifying retrofitting into existing shaker houses. The shaker comes standard with a fume-extraction hood to reduce operator exposure to drilling fluid vapors and prevent splashing outside shaker boundaries. It has one scalping deck and two primary decks of automated solids control, creating lower waste volumes. Higher feed rates increase project upside and reduce repairs. Two modes of operation, 6.3 G’s of progressive elliptical or 7.2 G’s of balanced elliptical movement, are available with a single-switch adjustment. Screens are held in place with pneumatic actuators; the user deactivates the pneumatic pressure and removes the lightweight composite screens for replacement.

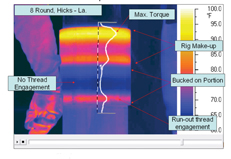

Tubular connection thermal imaging

The Shoulder/Thread Verifier (STV) system from Global Systems Inc. is a newly developed technology for monitoring connections among tubulars, tools and other types of equipment that use threaded joints in the petroleum industry. Unlike devices that directly measure the torque applied to the connection, the STV system uses thermal imaging to measure the relative thread engagement of different parts of the connection. This gives a clear, comprehensive picture of how the connections are making up, allowing the identification of connection problems that cannot otherwise be detected easily. The system works by recording and analyzing the infrared radiation emitted by connections as they are being made up. Coulomb’s laws dictate that the amount of torque applied to the pin by the operator’s tongs be equal to the total amount of torque applied to the pin by the box, or the sum of the torque applied in all the parts of the connection. This torque comes from friction—which is a conversion of kinetic energy into heat—between the pin and the box. The heat generated by friction raises the temperature of the pin and box at and near the points where the friction is applied, and the increased temperature results in increased infrared radiation, which the STV cameras detect, effectively showing from where in the connection the friction is coming. Knowing where the friction is in the connection allows technicians to identify potential problems as the connection is being made up. Thermal images of the connection are compared with the manufacturer’s specifications regarding which parts of the pin and box should be bearing what proportion of the friction and applying what amount of torque. This information is displayed in real time, before the connection is sent downhole. Two thermal cameras are positioned about 180° apart to give a full-circle view of the connection. These feed data to technicians’ laptops, where the connection’s makeup or breakouts can be analyzed.

|