Two decades of 4D geophysical developments—experiences, value creation and future trends

Seismic data continues to be the high-value leader in time-lapse monitoring, but gravity, EM and other methods will come into use in the near future.

Seismic data continues to be the high-value leader in time-lapse monitoring, but gravity, EM and other methods will come into use in the near future.Ivar Sandø, Ola-Petter Normann Munkvold and Rigmor Mette Elde, StatoilHydro Twenty years after the first 4D pilot run by StatoilHydro—on Oseberg Field followed by the full-field application on Gullfaks Field—towed-streamer, time-lapse seismic technology is still the dominant geophysical reservoir-monitoring method. The technology has proven to be an excellent enabler for improved Geophysical Reservoir Monitoring (GRM) and, thus, an important source for value creation in the petroleum industry. Today, more than 75% of StatoilHydro (SH)-operated fields employ time-lapse seismic, and seismic monitoring is an integral part of the company’s reservoir management. Cooperation with contractors and service industry has been of vital importance to produce the best technology solutions. The total number of SH-operated 4D surveys is now more than 100, Fig. 1.

Experience has pointed at the need for more dedicated 4D surveys using dense cross-line sampling, straight-line acquisitions and streamer steering. Since the introduction of marine 4D seismic in the early 1990s, SH has piloted a large spectrum of new technologies and applied these to solve various reservoir challenges. For example, since 1998, the company has successfully applied gravimetric monitoring of gas production from a number of its fields. In addition, it has applied 4D gravity to monitor CO2 sequestration. In this article, we first review experiences from a broad spectrum of applications of 4D technology. Based on these experiences, we predict possible future trends for its use in reservoir management. TECHNOLOGY DEVELOPMENTS AND VALUE CREATION There are several applications of 4D seismic, including, among others, identifying drained areas, locating undrained reservoir compartments, optimizing well placement, reducing uncertainty in reservoir development and production decisions, discriminating between reservoir fluid and pressure changes, discriminating between compacted stretching and stress changes in overburden, and monitoring CO2 sequestration. It was introduced in the early 1980s but only became commercial in the late 1990s. In the North Sea, 4D seismic was investigated on a full-field scale in about 1995 in a joint Statoil-Schlumberger project at Gullfaks Field. Detectable time-lapse signals were measured and proved to be of economic value in identifying drained and undrained areas. Soon after this, 4D surveys were acquired over several Norwegian and UK North Sea fields, including Schiehallion, Foinaven, Draugen, Troll, Oseberg, Norne, Statfjord, Forties and Gannet. In 1996, StatoilHydro started a research project to investigate the potential of 4D gravity to monitor gas production and seafloor subsidence, realizing that gravity is sensitive to height changes such as subsidence. The 4D gravity method was proven over Troll Field, with benchmark deployment in 1997 and repeat surveys in 1998, 2000 and 2002. The company is currently running gravity monitoring projects on five Norwegian offshore fields: Sleipner, Troll, Mikkel, Midgard and Snøhvit, as well as a trial at Ormen Lange. The following section addresses ongoing monitoring results from several of SH’s producing fields. Gullfaks full-field reservoir management: A cash machine. On Gullfaks Field, 4D seismic data play a significant role in management of tail production.1 These data have increased SH’s understanding of both the static properties and the dynamic behavior of the field, challenging the production strategy and driving the reservoir-management decision process. The data have identified bypassed volumes in unswept reservoir compartments, improved the estimate of remaining reserves and associated uncertainties, and helped to identify drilling hazards that have evolved over the lifetime of the field. Since the first repeat seismic survey in 1996, 4D data have been integrated into a multidisciplinary Improved Oil Recovery (IOR) effort that aims to recover 70% of the in-place reserves from a structurally complex and heterogeneous reservoir sequence. The 4D seismic has directly contributed more than 19 successful infill wells (Fig. 2) and generated a net present value of around $1 billion, while the total cost of the 4D seismic is about $60 million.

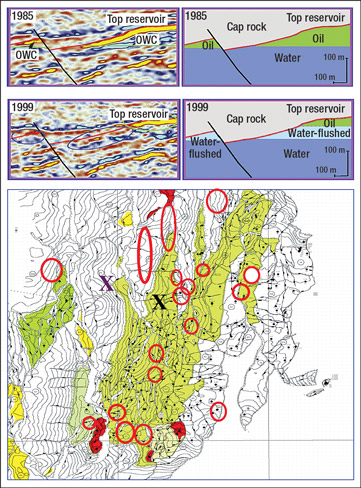

Oseberg Field: From a 4D pilot to quantitative reservoir management. On the Oseberg oil field, the main production strategy is upflank gas injection, creating the possibility of monitoring gas movement toward the downflank producers. The successful Oseberg 4D campaign is based on a feasibility pilot that uses repeated 3D seismic in a proper 4D setting for the first time worldwide.2 The initial exploration 3D was shot in 1982, but, as a basis for modern 4D technology, new surveys for the pilot were shot by StatoilHydro in 1989 and 1991. These were the first surveys where the nominal parameters between the acquisitions were maintained unchanged, thus giving repeatability that even today is considered useful for 4D work. The 4D campaign on Oseberg has been a technical and economical success (based on surveys in 1992, 1999, 2004 and 2007) and has been used for implementation of modern quantitative 4D techniques, such as giving elastic inversion estimates of Vp/Vs changes over time, which supported the interpretation of pressure vs. saturation changes in the reservoir units. The recent vintages are actively used for monitoring both the gas-oil front and the water-oil front in the reservoir, Fig. 3.

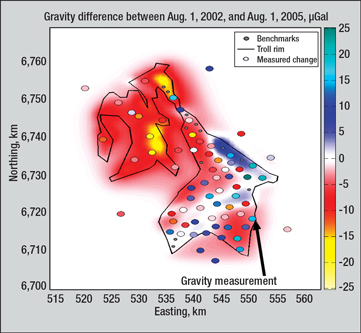

Troll Field: Tailor-made solutions. Due to the very large area of the Troll East gas field, repeated full 3D surveys were not considered economically feasible in early field development. As an alternative, StatoilHydro proposed and is currently running a campaign based on repeated 2D acquisitions, where the vessel is towing a very dense spread of streamers. In this way, a very high degree of receiver position repeatability is obtained, yielding 4D signal/noise ratios. The repeated 2D lines have been used to map pressure depletion due to gas production, and an average pressure drop of 15 bar has been detected from the seismic data.3 Full-field gravity data have been acquired to complement the 2D time-lapse seismic data and to map the water influx; to date, four relative-gravity repeats have been acquired.4 The gravity data have proven valuable in updating reservoir understanding and locating remaining reserves. The 4D gravity anomalies represent a smoothed version of the reservoir mass changes shown in Fig. 4. Due to the encouraging results from the repeated 2D seismic lines, a full-field 3D seismic repeat survey was acquired in 2008 to map water influx and pressure depletion in greater detail.

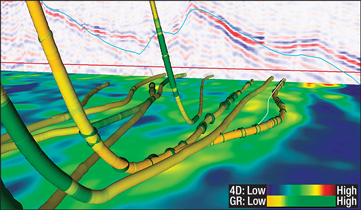

The relative gravimeters developed by SCRIPPS and SH provide unparallel accuracy in offshore applications when compared with the rest of the industry. The precision has improved by an order of magnitude over the last decade, reaching a repeatability of 4 mGal in the last survey. In the Troll West area, the main challenge is to monitor production from a very thin oil column (10−20 m) over a large area (770 sq km). The main production effect seen on 4D data is the gas cap expansion and its influence on the thin oil column. Before a full-field 4D implementation was initiated, a 3D pilot was run in 1998 to demonstrate the ability of towed streamer technology to detect even very small changes in the oil column. The successful pilot triggered the current 4D campaign that is now an integrated part of GRM of the field. Workflows for qualitative and quantitative interpretation have been developed.5,6 Their applications range from identification of IOR targets to optimized well placement for infill drilling and well completion. Figure 5 shows an example of wells that have been optimized based on 4D information. The horizontal plane represents the oil-water contact, and the colors are 4D amplitude differences. No horizontal infill wells are drilled without 4D approval.

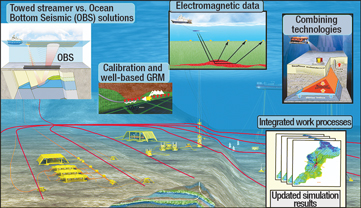

As a result, every year, an average of four new targets are identified from 4D data, while all wells drilled are optimized with respect to both well placement and well completion, yielding increased recovery. Accumulated value creation approximates $100 million per year. FUTURE TRENDS The future holds requirements related to even shorter response times and shorter turnaround times for time-lapse seismic data acquisition, data processing, interpretation and, ultimately, the model-updating procedures. The challenge lies in reducing the time spent on this chain from months or years down to days or weeks. Today many 4D seismic applications are qualitative or at best semi-quantitative; i.e., the time-lapse data is used to identify areas of changes in saturation and pressure distributions between seismic survey times. The need for being more quantitative is already here, to estimate not only the kinds of changes but also the size of these changes in saturation and pore pressure. In the rapid workflows of the future, quantitative interpretation methods will be an integral part. Reservoir monitoring through 4D geophysical data will continue to be an integral part of reservoir management. In the future, the focus will be on even more tailor-made and integrated solutions, from acquisition to integrated workflows. Some of the main future needs are: Some of the key elements to fill these gaps in today’s GRM projects are sketched in Fig. 6.

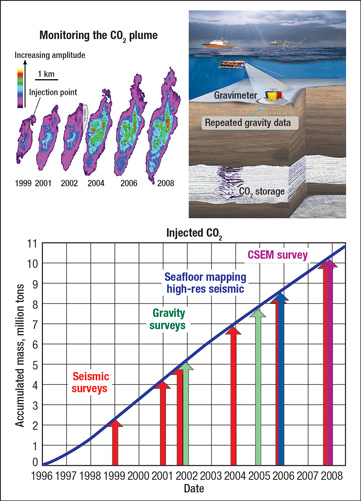

Towed streamers vs. ocean-bottom solutions. Here, the future scenario will enable tailor-made solutions. Cost/benefit evaluations will continue to be the most important factor when deciding on final solutions. Requirements related to repeatability, 4D robustness and desired survey-acquisition timing intervals are also important issues. In 2008, the first field pilot of permanent seismic monitoring systems based on fiber optic technology was performed on Snorre Field. The pilot was a technical success in the sense that it provided good results with respect to seismic data quality and improved repeatability (generally, normalized root-mean-square ratio improvements ranging from 20−40% to 10−20%). It is also used to design future work processes for multidisciplinary teams that will exploit the increased 4D information inherent in these high-quality data sets. Calibration and well-based GRM. The use of downhole geophysical monitoring are twofold: to collect data for calibration of 4D seismic data, and to perform localized monitoring of the production behavior. Since StatoilHydro’s need is to make greater quantitative use of its geophysical GRM data, the need for proper calibration is crucial. If sufficient calibration is done by comparing Production Logging Tool (PLT) results with quantitative 4D results in the near-borehole zone, SPLT (Seismic PLT) may replace traditional PLT measurements. Electromagnetic data for GRM. Since EM methods provide potentially good estimates of the resistivity field and therefore saturation changes, these methods are in principle well suited for GRM. Controlled-Source ElectroMagnetics (CSEM) will probably be used in the future for better mapping of saturation changes in the reservoir. These methods are quite immature, but SH is currently evaluating the potential of both traditional surface-mode CSEM and downhole solutions that provide local images of the resistivity fields. Combining technologies. It is already demonstrated that combining several independent geophysical measurements increases the value of GRM. As an example, the Sleipner CO2 project serves as an excellent workbench for piloting methods for integrating independent geophysical monitoring tools, Fig. 7.

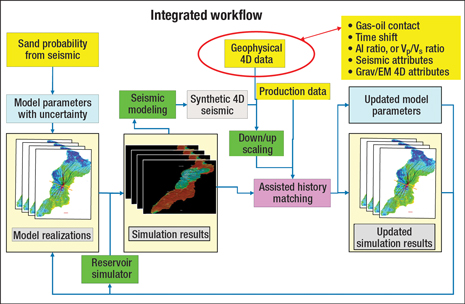

On Sleipner Field, carbon dioxide is captured from the Sleipner natural gas processing facility and injected into the subsurface for environmental reasons. To monitor development of the CO2 plume, gravity and seismic data are combined. Six repeated seismic surveys have been acquired, and the geophysical monitoring confirms that no leakage has occurred. Repeat surveys through 12 years have revealed both an expansion and densifying of the CO2 plume. Distribution estimates of the CO2 saturation have been made from 4D seismic data combined with an understanding of CO2 flow, with reasonably accuracy. Gravity monitoring has also been tested at the Sleipner site, and a time-lapse signal from the injected CO2 has been detected. This constrains the in situ density, which otherwise is poorly determined, because the CO2 has densities and temperatures close to the critical point. In Fig. 7, the different acquisitions are posted, in time, together with the accumulated mass of CO2 injected into the reservoir. In this case, the mass change over time is precisely known. This provides a good chance to test quantitative GRM methods. Also, in 2008, a CSEM survey was acquired over the field, which opens up possibilities to include EM information in future GRM evaluations. Figure 8 summarizes the integrated model workflow. Several geo-realizations are generated based on the model parameters and their uncertainties. We are using the uncertainty module in RMS. A sand-probability cube from seismic is used to constrain the modeling. All geo-realizations are input to flow simulation in Eclipse software. In the history matching process, we use an assisted history-matching method where the model parameters are updated to match historical data and well-production data, as well as 4D seismic. The output is a new set of models with updated model parameters. The updated model parameters can then be fed back to the geo-modeling in RMS, and in this way we get consistency between the geo-model and the simulation model.

ACKNOWLEDGMENT Thanks to the many StatoilHydro 4D specialists whose shared wisdom and knowledge are aggregated in this article. Special thanks to the asset teams at Gullfaks, Troll, Oseberg and Sleipner Fields for valuable input. LITERATURE CITED 1 Williams et al., “4D seismic case study in reservoir management: The Gullfaks Field, offshore Norway,” presented at the SPE/AAPG/SEG Workshop, Galveston, Texas, 2008.

|

|||||||||||||||||||||||||||||||||||||||||||

- Quantum computing and subsurface prediction (January 2024)

- Mixed outlook for activity on the UK Continental Shelf (December 2023)

- Machine learning-assisted induced seismicity characterization of the Ellenburger formation, Midland basin (August 2023)

- What's new in exploration (March 2023)

- Seismic and its contribution to the energy transition (January 2023)

- First Oil: Sorting through the muddled mess (November 2022)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)