An integrated brownfield study improved production forecasting.

Clas Normann, Talisman Energy

With exploration costs on the rise and energy demands steadily increasing, oil and gas companies are seeking ways to maximize the production of their mature fields and, where it makes sense, drill new wells in existing reservoirs. With this objective in mind, Talisman Energy conducted an integrated field study of the Gyda South reservoir in Norway, which had been in production since 1995. The goals of the study were to recalculate field reserves, gain a better understanding of well behavior and obtain a more accurate estimate of future production. A dedicated project team—consisting of a reservoir engineer, a geologist and a geophysicist—was assembled for the purpose of this study: to ensure that Gyda South reserves are fully tapped and that future production is secured despite challenging field characteristics and mitigating circumstances, such as rapid water breakthrough.

GYDA SOUTH FIELD

Gyda South is an offshore field located about 240 km southwest of Stavanger, Norway. The field is a four-way, dip-closed structure with a small amount of normal faulting. The reservoir rock is sandstone, deposited in a prograding shoreline depositional environment. Average reservoir permeability is approximately 100 mD. The field contains a light oil with a bubble point of approximately 350 bar and a gas-oil ratio of approximately 600 m3/m3. At the time of the study, there was no primary gas cap in the field.

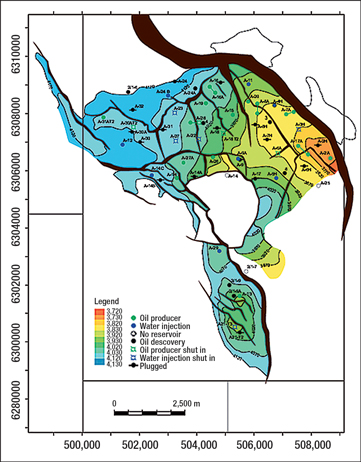

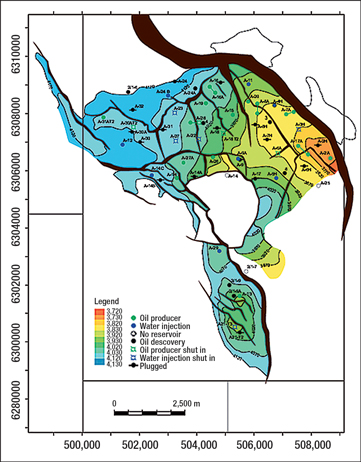

A single production platform with a total of 32 slots produces oil from the Gyda, Gyda Southwest and Gyda South Fields. Gyda South production is from one well, Well A-13, supported by two injection wells, Well A-21 and Well A-29, Fig. 1. Initial production was approximately 12,000 bpd. Production experience showed that high connectivity exists between Well A-21, the southerly injector, and the producing well. As a result, rapid water breakthrough occurred, prompting Talisman Energy to conduct an integrated field study that would help identify the problem and stem the breakthrough.

|

|

Fig. 1. Location map of the Gyda Field asset.

|

|

FIELD STUDY DETAILS

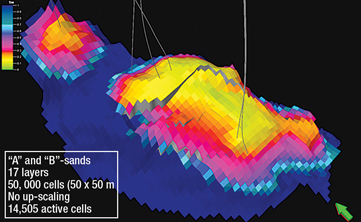

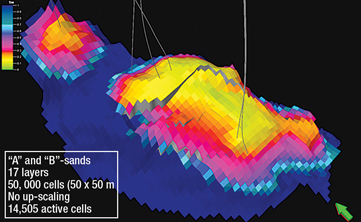

From an existing geophysical interpretation, the Talisman Energy project team developed a new static model of the field. They built dynamic models from the static geological model without up-scaling to better reflect geologic heterogeneity in the simulation model. A compositional reservoir simulation model was used with a six-hydrocarbon component fluid description, and 17 layers representing the “A” and “B” sands of the Gyda reservoir, Fig. 2.

|

|

|

Fig. 2. Dynamic simulation model of the Gyda South reservoir.

|

|

The simulation model was history-matched with current production data. Early versions of the model predicted bottomhole pressures in the producing well significantly higher than those observed in the field. The project team improved the match between the predicted and observed bottomhole pressures by reducing the pore volume in the model. The geologist and reservoir engineer then modified the geological model’s porosity distributions while taking into account known influences on porosity, such as diagenesis on the flanks of the field. To ensure overall geological consistency, appropriate equivalent multipliers were applied to the permeability and net-to-gross ratio. The multipliers were not old-fashioned squares put in by the reservoir engineer, but rather consistent maps made in cooperation with the whole team. These changes were then cascaded into the reservoir simulation model, ensuring that the simulation model remained consistent with the geological interpretation and increased the team’s confidence in predictions.

The high connectivity between the injector, Well A-21, and the producer, Well A-13, was modeled by enhancing permeability in parts of the model. The distribution of the permeability enhancement was based on seismic and other data. In the Gyda area, an instantaneous amplitude attribute was found to be a good guide to reservoir quality at reservoir depth. Other factors affecting the level of communication in the reservoir were gross reservoir thickness and an overall trend with depth, which were considered in mapping the level of permeability increase.

FIELD STUDY BENEFITS

The study yielded several insights and benefits. The creation and simulation of multiple geological realizations helped the team understand the implications of uncertainties associated with the static and dynamic models. Variables used by the geologist to generate the maps were parameterized and allowed to vary within the expected ranges, making it possible to produce and simulate hundreds of realistic and equally probable geological realizations automatically. In order to forecast future Gyda South Field production in a number of different scenarios using different injection rates, the history-matched model was used. The collaborative environment enabled the different disciplines within the project team to keep interpretations and models synchronized throughout the study. This ensured consistency and increased the team’s confidence in their production predictions made using the history-matched simulation model.

FIELD STUDY RESULTS

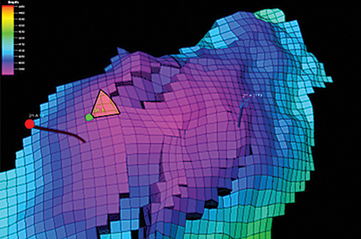

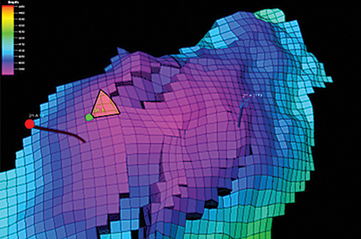

The study produced a reliable simulation model that was used to optimize injection rates and design an additional producer well, Fig. 3. The simulation results showed that Gyda South production could be maximized by ceasing injection into Well A-21. The secondary gas cap, formed during production to date, was deemed sufficient to support production by expansion and that continued water injection into Well A-21 would simply drown the producing well. The new model showed that the gas cap will provide natural gas lift, significantly enhancing future production.

|

|

Fig. 3. Design for the new Gyda South well.

|

|

The simulation also showed that a significant amount of oil in place was not accessible using the existing production well. The extra reserves were located behind faults on the flanks of Gyda South.

TECHNOLOGY TOOLS AND TECHNIQUES

Providing a means of team collaboration was considered a top priority of the study. Integrated workflows were used across the multidisciplinary team to keep all the project data in sync and enable simultaneous viewing. A single E&P application, Petrel* seismic-to-simulation software, was implemented as the geophysical interpretation and geological modeling tool and also served as the front end to the ECLIPSE* reservoir simulation software. This allowed the team to preserve domain knowledge with a consistent earth model representation throughout the study and provided a single interface to easily access shared information.

History-matching techniques were critical in the success of this project. Once a model was adjusted to closely reproduce the reservoir’s past behavior, it could be used to simulate future reservoir behavior with a higher degree of confidence, since the adjustments were constrained by known geological properties in the reservoir.

The “process manager” tool, within the seismic-to-simulation software, allowed the team to capture data parameters and relationships that automated the process and enabled rapid updating of reservoir models as new information from the wells became available. It also enabled the geophysicist and reservoir engineer to create multiple model realizations to assess the impact on reserve volumes.

SUMMARY

The integrated field study increased understanding of the reservoir and confidence in the production forecasts based on the newly created simulation model, as it remained consistent with the geological interpretation. The new model will be used to collaboratively design another well to effectively tap the Gyda South reserves and increase future production. The main challenge for the design and location of a new well will be to understand the gas-oil contact movement with time in the reservoir.

The study was performed in 2007, and history has confirmed the model as a very good prediction over the last two years. Recently, the gas cap has expanded down to the perforations of the well, giving an increase in the gas-oil ratio as predicted by the model.

* Mark of Schlumberger.

|

THE AUTHOR

|

.jpg) |

Clas Normann has 14 years of experience in the oil industry as a reservoir engineer. He previously worked eight years for Eni and three years for Schlumberger. Currently, Mr. Normann works for Talisman Energy as a reservoir engineer at the Gyda Field in the North Sea. He received an MSc degree in petroleum engineering from the University of Stavanger in 1995. His main areas of expertise include reservoir modeling, history matching, improved oil recovery and risk analysis.

|

| |

| |

|

|

.jpg)