Rotary steerable and geosteering technologies enable rapid field redevelopment.

Jim Manson, Andy Stewart, Martin Pendlebury and Emily Ferguson, Maersk Oil, UK; Ukpe John, Ian Tribe and Rebecca Lepp, Schlumberger

Dumbarton Field, operated by Maersk Oil, UK, is located in UK North Sea Block 15/20. During its life, the field presented numerous drilling challenges, which hampered its development. These include formation instability, directional drilling control issues and thin, complex reservoirs that were poorly imaged by seismic. Drilling is further complicated by transition drilling—alternating zones of fast drilling separated by slow-drilling, hard, abrasive stringers. The field pore pressure gradient is 9.07 ppg equivalent mud weight; but to maintain wellbore stability, mud weights up to 11.6 ppg are required. Because of these and other challenges, traditional mud-motor directional drilling has been sub-optimal.

Discovered in 1987 by BP, the field was originally Donan Field. The discovery well, 15/20a-4, and a single development well, 15/20a-6, provided production during the subsequent 10 yr and accounted for a cumulative 15.3 million bbl of oil. In the latter half of the 1990s, additional horizontal development wells were planned to replace the two producers. Five attempts were made, but all failed due to wellbore stability issues. BP continued production from the original two wells until 1997. Watercut had reached 71%, and production ceased to be profitable.

Maersk Oil UK acquired the field and assessed the seven wells in the vicinity that intersected oil in Paleocene sandstones. These included the wells of Dumbarton/Donan Field and the smaller Pladda Field to the east. The reservoirs are low-relief, areally-extensive structures with thin oil legs from 30-ft to 100-ft thick, which are aquifer driven. Well tests were performed in one Jurassic and three Paleocene sequences; each flowed oil at 3,000 bpd. Production was good quality, undersaturated oil with a gas/oil ratio of about 400 ft3/bbl and an API gravity of about 40°. The reservoir sits atop a thick Balmoral sand package with average porosity and permeability of 30% and 1 Darcy, respectively. The sand is layered with thin, laterally-extensive shales.

The deciding factor for the redevelopment was the revelation that the original oil in place was estimated at 150 million bbl. Almost 90% of the oil was still in place. In addition, the economic climate had changed dramatically since the late 1990s. Accordingly, five production wells were planned to exploit the field along with a single water injection well.

RECOMMENDATIONS

The plan was to place five producers in the Balmoral sandstone at least 40 ft above the Oil/Water Contact (OWC). Horizontal drainholes were to be drilled and logged to intersect at least 120 ft of high-quality sand to confirm that the wells were properly placed. After studying data from previously drilled wells, the team recommended that the wells be geosteered using real-time Logging-While-Drilling (LWD) data. Steering was to be accomplished using the PowerDrive Xceed rotary steerable system for harsh, rugged environments.

This system was chosen because steering is done by internal orientation of the toolface. With exceedingly soft sediments between the hard streaks, it was forecast that pushing against the soft borehole walls could be problematic and affect steerability. With this Rotary Steerable System (RSS), there are no stationary external parts or pads, which reduces the risk of differentially sticking the BHA and minimizes axial friction. The 9.0-in. tool was chosen for the 12¼-in. vertical and curved-hole sections, and the 6¾-in. tool was chosen for the 8½-in. lateral sections.

12¼-IN. SECTION

The surface and build sections were to be logged using the geoVISION imaging-while-drilling tool, arcVISION array resistivity compensated tool, and adnVISION azimuthal-density-neutron porosity tool (see World Oil, March 2006, p. 71). These LWD tools were to be supported by the TeleScope high-speed, telemetry-while-drilling, power and combinability tool. This BHA would be used for landing the well in the target sand.

The imaging tool provides three measurements: resistivity at-the-bit, high-resolution ring resistivity, azimuthally-focused resistivity and a near-bit gamma ray measurement. The three-button electrodes are along the axis of the tool and measure at three different investigation depths to profile near-wellbore, mud-filtrate invasion. The array resistivity tool provides deep-reading phase shift and attenuation resistivity.

The azimuthal-density-neutron tool has detectors in an integral blade stabilizer, thus minimizing the mud signal. Because of its position, it scans the circumference of the borehole to produce 16 independent-sector- and four quadrant-sector-oriented porosity images. The up- and down-quadrant images are transmitted in real-time and enable interpretation of apparent formation dip.

When drilling down-section stratigraphically, the lower-quadrant density will “see” a formation change before the upper-quadrant density. When drilling up-section, the opposite occurs. The difference between the times the quadrants detect the formation change can be translated to the apparent intersection angle of the formation boundary with the borehole. Then, by knowing the borehole inclination and direction, formation dip can be derived.

The high-speed, telemetry-while-drilling tool contains a turbine power generator, telemetry pulser and four-axis vibration sensor. It also contains toolface, direction and inclination, gamma ray, downhole torque, rpm, weight-on-bit and annular pressure-while-drilling sensors.

Of particular value in transitory hard/soft drilling sections is the four-axis vibration measurement. By studying the vibration patterns in real time as the bit drills, engineers can adjust drilling parameters to optimize penetration rate and maximize bit life. The system measures lateral (x-y) vibration, axial (z) vibration and torsional vibration, or stick-slip.

8½-IN. SECTION

In the horizontal sections, real-time geosteering was to be driven by information supplied mainly by the PeriScope bed-boundary mapper tool, as well as the EcoScope multi-function formation evaluation system. The system provides integrated resistivity, formation density and compensated neutron measurements from a single collar. Additionally, the system offers elemental capture spectroscopy and sigma logs for mineralogical interpretation of the formations drilled. The imaging and telemetry tools from the vertical- and build-section drilling would be retained for the horizontal sections. This BHA was to be used to geosteer the wellbore through the highest-quality reservoir rocks.

The bed-boundary tool can detect more than 20 ft radially around the borehole. It detects and maps boundary strata and fluid contact levels for steering adjustments on-the-fly. The measurements allow calculation of distance to the boundary and its apparent dip.

PROJECT PLANNING

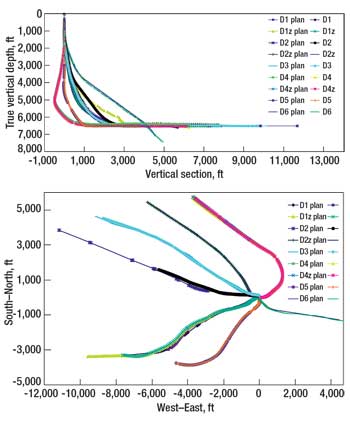

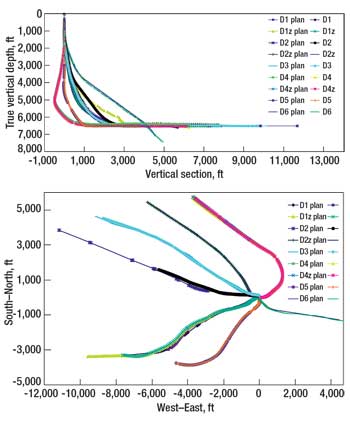

The new wells were designed in 3D to optimize reservoir coverage and ensure efficient landing in the target zones. The plan was to nudge each wellbore deviation out to about 8° rather quickly in the 17½-in. surface hole to clear the other wellbores, and then maintain a straight course until it was time to build, steer and land at 90° deviation in the target zone. After setting pipe, the 8½-in. lateral section was to be geosteered to obtain optimal placement within the reservoir, Fig. 1.

|

|

Fig. 1. Well plans (thin lines) are compared with drilled trajectories (thick lines) for the six Dumbarton wells in cross-section and plan views.

|

|

General instructions were written to allow decision flexibility in the lateral section, depending on real-time measurements. More detailed instructions evolved, based on information from each well as it was drilled. The produced-water, reinjection well was handled separately.

All the challenges previously noted from the early drilling attempts manifested themselves in the Dumbarton redevelopment project. The difference was that the engineers were better prepared. Solutions had been developed for the abrasive Alba sands, water ingress in the Alba, tight stringers at the base of the Alba and massive sand cuttings that blind the shale shakers. Water-sensitive shales and clays were addressed using oil-based mud. Optimum mud weights were predicted for each formation.

Real-time annular pressure-while-drilling measurements would help manage Equivalent Circulating Density (ECD) within tightly specified operating windows, which were critical to the management of wellbore stability risks within the 12¼-in. and 8½-in. hole sections. The real-time LWD measurements would help resolve geological uncertainties in the lower Balmoral sands at the heel land-out, as well as true vertical depth uncertainties. When the original wells were drilled, this technology did not exist.

Well plans were ranked by geological uncertainty and were to be drilled in ascending order to take maximum advantage of information from each successive well and reduce uncertainties in subsequent wells. Drilling engineers decided to use a point-the-bit RSS for the 12¼-in. section as well as the 8½-in. section. Although the larger 9-in. RSS had never been run in the North Sea, its proven ability in the smaller 6¾-in. version earned it the job.

The oil-based WARP mud was chosen because it offered shale stability and high lubricity for the complex drilling profiles. The fluid has micron-diameter barite particles, producing lower viscosities and lower ECD. It was chosen for both the 12¼-in and 8½-in sections. It also allowed the use of finer-meshed shale shaker screens. In effect, the new fluid allowed a single fluid to be used for both hole sections, leading to better fluid logistics and ECD management.

The land-out strategy for each well was given high priority. The operator believed that the wells could be landed within 1-ft TVD. Directional targets were more loosely defined, because the wells could be steered to intersect the best-quality reservoir sections, which would be defined in real-time as the laterals progressed. At the same time, special consideration was given to dogleg severity and BHA bending to build a high-quality well trajectory.

Geological uncertainties necessitated some flexibility in case the well bottomed-out in shale. The operator agreed to drill ahead up to 2,000 ft to find sand before dropping the well trajectory to another level. They recognized and accepted that it might be necessary to pull back and sidetrack to find sand, and this was built in as a contingency. A biostratigraphy contractor was engaged to support the land-out with real-time stratigraphic positioning of the bit within predetermined marker horizons as an extra measure of certainty to the landout placement.

PROJECT EXECUTION

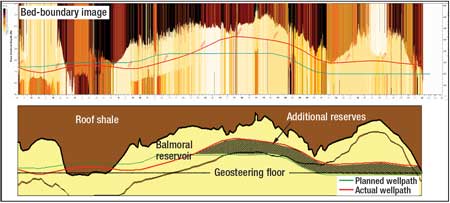

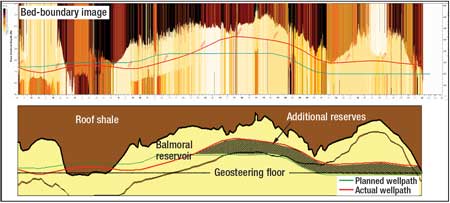

LWD modeling and interpretation in real time proved beneficial in both drilling the intermediate build sections and the lateral drainholes. The operator wished to place the wellbores close to the reservoir ceiling, and at least 40 ft above the field’s water level. This provided access to attic oil, while delaying water incursion. A combination of log interpretation and cuttings analyses ensured that the wells were placed correctly, Fig. 2.

|

|

Fig. 2. Engineers were able to drill close to the reservoir ceiling while staying away from the oil-water contact.

|

|

The bed-boundary tool played the major role in helping to place the laterals very close to the reservoir ceiling without drilling out of zone. Previous experience had shown that once the reservoir was exited, it would be very difficult to recover. Although the top of the Dumbarton is undulating and faulted, the ability to image bed boundaries in real time allowed the wellbores to be steered to continuously “plane” the reservoir top. For the five wells, an estimated 14,000 ft of additional reservoir sand was opened with 60% average net-to-gross pay, thereby increasing field production potential.

Lateral and vertical borehole uncertainties were minimized using BHA bending calculations and geomagnetic referencing corrections. Aerial magnetic surveys were used to compensate for drillstring-induced magnetic variations. Data were integrated at the Operation Support Center in Aberdeen and returned to the wellsite at frequent intervals.

For future operations where TVD uncertainty is critical, the authors recommend a continuous trajectory approach. Continuous trajectory processing will produce the most accurate description of the well path. It uses continuous while-drilling inclination and azimuth measurements to build a higher-resolution survey describing all wellbore deflections.

RESULTS

Using a batch drilling technique, all the top holes were drilled first, then all landing sections and, finally, all reservoir sections. Within a span of six months, six wells were delivered, including three sidetracks. All wells penetrated more reservoir rock than prognosed and all were drilled faster than expected. Initial production from the five producers exceeded expectations.

Casing was set in all six wells and all wells met the landing criteria, except one. It was used as an exploration/appraisal well to test an alternative landing target. This well was plugged back, sidetracked and landed in the alternate zone.

In the reservoir sections, two of the wells encountered faults. Both were successfully sidetracked away from the faults and all six wells were satisfactorily completed.

Project success was attributed successful wellbore placement from running the RSS and LWD tools, coupled with the real-time drilling evaluation and assessment process. In summary, RSS avoided any stuck pipe incidents and allowed the wells to be steered to meet the challenging geological objectives as the wells progressed. Geological risk and steering decision management was aided by real-time LWD data modeling, which reduced wellbore positioning uncertainties. ECD management and wellbore stability issues were key to maintaining the wellbores until casings and completions were safely in place.

Interpretation of azimuthal LWD measurements is a powerful technique for confirming well position, establishing whether drilling-up or -down stratigraphic section and providing formation dip. Real-time image logs proved extremely useful for geosteering these wells.

Using directional, deep resistivity data, the five wells netted an additional 14,000 ft of reservoir sand with 60% average net-to-gross pay. The result was better than what could have been achieved with conventional technology. The directional drilling technology allowed the placement of the wells at optimal distances from the OWC and increased potential field recovery.

ACKNOWLEDGEMENT

This article was derived from IADC/SPE 112365, which was presented at the 2008 IADC/SPE Drilling Conference held in Orlando, Florida, from March 4–6, 2008.

|

THE AUTHORS

|

| |

Jim Manson earned a BSc in civil engineering from the University of Edinburgh and an MSc in petroleum engineering from the Strathclyde University. During the Dumbarton development, he was both Senior Drilling Engineer and Drilling Superintendent for the project. Manson is presently HPHT team leader for Maersk Oil North Sea and is a Chartered Engineer, registered with FEANI.

|

|

| |

Andy Stewart earned a BSc Honours in geology from Strathclyde University and has over 30 years of experience in drilling and completions in varied locations. He was Well Engineering Manager for Maersk Oil North Sea during the Dumbarton development drilling phase. Stewart is presently Drilling Manager with Maersk Oil Houston.

|

|

| |

Martin Pendlebury earned an BSc degree with Honors in geology from Edinburgh University. He has worked as a wellsite geologist, and has extensive experience in the planning and execution of horizontally geosteered wells in both the southern and northern North Sea. Pendlebury is a Consultant Operations Geologist working with Maersk Oil North Sea UK, a position he has held for the last three years.

|

|

| |

Emily Ferguson earned a BSc degree in geology and petroleum geology and an MSc in petroleum geology from the University of Aberdeen. She was Project Geologist for the Dumbarton Field development during the placement of Phase I wells. Furgeson is presently an Exploration Geologist with Maersk Oil North Sea in Aberdeen.

|

|

| |

Ukpe John earned a BS degree in petroleum engineering from the University of Port Harcourt, Nigeria. During his 15 years in the oil industry, he participated in high profile development projects in Nigeria, Caspian, North Sea and Angola. John is Drilling Services Manager for Schlumberger in Luanda, Angola, a position he assumed in August 2007.

|

|

| |

Ian Tribe earned a BS degree in geology and computer science from the University of Reading and a PhD degree in structural geology from Oxford Brookes University. He began his oilfield career in 1995 with a UK-based geological consultancy. Tribe is the Schlumberger Account Manager for Drilling and Measurements, based in Aberdeen.

|

|

| |

Rebecca Lepp earned a BSc degree in geological science from Oxford Brookes and an MSc in petroleum geology from Imperial College London. Lepp is presently the Training and Staffing Manager for Data & Consulting Services, Schlumberger, based in Paris.

|

|

| |

|