Its automation, low profile and low environmental-impact characteristics make it well-suited for drilling in the Barnett Shale.

Perry A. Fischer, Editor

The rig the title refers to is the HH series of hydraulic-hoist, automated rigs. First introduced to the drilling world in 1995 after a long development process with Eni and Agip, these rigs made themselves known to the oil and gas industry outside of Italy in the early 2000s, as they became more powerful and capable of drilling deeper holes. We first published information on these rigs in 2003-2004 (see World Oil, April 2003, April 2004 and December 2004). There are six varieties, designated HH-100 through HH-300, which refers to their static hookload capacity (100-300 t).

Drillmec S.p.A., maker of these rigs, is a division of Italy’s Trevi Group, having been reorganized in January 2004 from the former Soilmec, the oil-, gas- and water-drilling division. More than 30 of these rigs are in use throughout the world, from Siberia to Africa, North and South America to China. This article is an update on experience with this rig in the Barnett Shale to date, including how the rig works, and what advantages and disadvantages come with its use.

HOW THE RIG WORKS

The HH series of hydraulic-driven drilling rigs are designed for low- to moderate-hookweight applications, which translates into shallow- to moderate drilling depths of about 10,000 ft, although a well was recently drilled to a 13,000-ft MD in the Barnett Shale with a 4,000-ft lateral. The rig can come in various configurations, but the focus here is on the automation and environmental aspects, with integrated trailer-mounted components. The driller can have full control of all operations from the cabin (which can be climate controlled), including automatic pipe handling, power tongs, slips, mud system and drilling parameters, Fig. 1. The HH rigs have a built-in top drive with an integrated torque wrench, and up to 600,000 lb of static hook weight. There are no massive mast structures with crown block and traveling equipment. Tripping of the drillstring and tubulars is done with a hydraulic cylinder, which allows mast height reduction and lightening. Its total input is about 1,300 to 1,600 hp.

|

|

Fig. 1. The driller’s cabin can control virtually all aspects of the automated drilling process.

|

|

Rig up/down. Both overall weight and the number of pieces to be handled and transported are reduced. The rig up/down operations should mean time saved moving between locations, with a commensurate reduction in moving costs, especially when drilling operations are short compared to the moving time, such as with shallow wells. But competitors have also made strides in shortening rig up/down/transport time.

Rig up/down operations are all hydraulically controlled, as are all rig components. The hydraulic unit is self-contained on a semi-trailer that is never disassembled for moving. The hydraulic system can be powered by a diesel or electric unit, deck installed and contained in a soundproof shelter.

The rig is integrated into a trailer. In fact, all loads are wheeled and self-erecting. Setup involves height adjustment (up to 30 ft) by means of hydraulic pistons, Fig. 2.

|

|

Fig. 2. The rig and its integral trailer are raised by a set of pistons.

|

|

The mast is self-standing and is raised by a pair of pistons. When this is achieved, the top drive and its cables are already in working position.

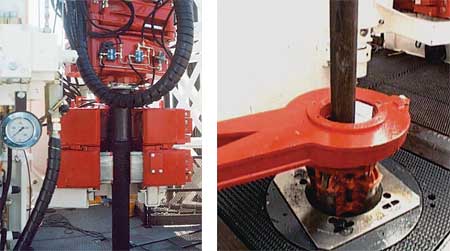

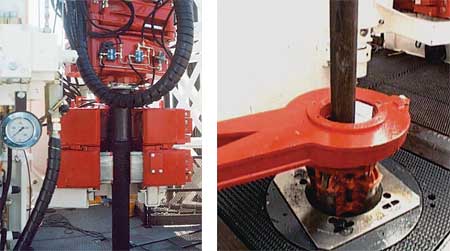

Running in/out of hole. The automated pipe-handling system and all tripping operations are remotely controlled, avoiding any contact by drilling floor personnel. Drill pipe is stored and transported in the white bins shown in Fig. 3, which are “fingered.” These are erected vertically in a semicircle. This arrangement allows a constant radius such that a “monkey arm” can reach out from the central mast and grab a pipe section from the carousel. The carousel rotates so that the “monkey arm” (also called a Rover) can grab the pipe and place it in the mousehole, where it is picked up by the top drive assembly, Fig. 3. Automated tongs and power slips complete the process before running the pipe into the hole, Fig. 4. Tripping out is essentially the reverse of the above.

|

|

Fig. 3. The “monkey arm” grabs the pipe from the white bins and puts it in the mousehole, where it is picked up by the top drive assembly.

|

|

|

|

Fig. 4. Automated power tongs and hydraulic-powered slips are controlled from a cabin and are an essential part of a fully automated rig.

|

|

Drilling parameters can be controlled during operations by the hydraulic top drive, which allows automatic drilling with a constant WOB or constant ROP, selected by the driller on the control panel. In case of stuck pipe, controlled and predetermined values of over-pull can be set and smoothly reached, and back-reaming can be executed while tripping out of the hole, reducing the risk of losing the drillstring.

Power system. The trailer-mounted power control room looks like a modern power plant. The hydraulic unit uses AC current, while the mud pumps use DC. Monitored via a Programmable Logic Controller (PLC), status and system messages are shown in user-friendly formats in central displays.

Avoiding complex switching for main drives and auxiliaries, the system eliminates interface problems. Optimized parameters for each motor can increase the economic use of the pump, drawworks or rotary table.

Mud pumps/system. Massarenti triplex mud pumps normally come with the rig (although Mountain is using LEWCO 1300 hp). They range from 300 hp to 1,600 hp for drilling, workover and cementing operations. HH rigs are designed to avoid any spillage of fluid from the drill floor, mud tanks, mud pumps, generator and ancillary equipment. This allows the rig to provide drilling service in a dry location, in accordance with ISO 14000 rules, with enhanced control on environmental pollution.

ADVANTAGES OF THE RIG

Automated rigs typically run at a steady, safe speed; this, together with fewer lost-time accidents, should mean that drilling time per well is less than from a conventional rig. The environmental benefits are noteworthy. Automation also allows a smaller crew, with fewer injuries. Statistics bear this out.

The environmentally friendly aspects are the most obvious. The rig has a low profile and has a relatively small footprint, Fig. 5. Mountain Drilling’s Rig 6 has an uncrowded footprint of 246 ft by 132 ft, or about three-quarters of an acre. It could be made even smaller.

|

|

Fig. 5. The small footprint and low profile of these rigs makes them unobtrusive when used near urban areas.

|

|

Complete mud-collecting ditches under the drill floor, mud pumps, substructure, tanks and vertical pipe bins guarantee a dry location. In addition to the ISO 14000 compliance for fluid containment, the rigs are relatively quiet, with at most 60 dB of noise at the drill floor. Noise reduction matters even more when drilling near homes and buildings. The diesel or electric motors, as well as the hydraulic oil cooling fans, are contained in a sound-reduction shelter. Also, the rig does not have drilling brakes, which are the most difficult source of noise to eliminate.

Schlumberger IPM is managing one of the rigs for Red Oak Capital Management. Jim Whipkey, one of the principals at Red Oak, said that they’ve kept the rig busy drilling near Bartonville, Flower Mound, Lantana and the Copper Canyon areas in the Barnett. Whipkey says, “Without a doubt, the environmental and safety aspects are the best features of the rig. I think that more and more companies are going to require that the rigs they use be demonstrably safer.”

As for the noise and low height, Whipkey says, “We’ve drilled within 300 ft of homes.” He adds, “In fact, we have used those aspects of the rig to our advantage in securing leases.”

Whipkey continues, “We feel that the rig is well suited for the Barnett.” When asked about trip time, he says, “Trip time is a function of a crew working together very smoothly. This is an automation situation, where the quality of the crew is very important in obtaining reasonable trip times.” As with many contractors, getting and keeping a well-trained crew has been a problem, but this situation is no different than most.

David Delao, drilling manager for Chesapeake in the Barnett Shale, said that the rigs have worked out well for the company. The company has been running more than 40 rigs in the Barnett, and two to three of these rigs have been the Drillmec type (Mountain Drilling) for the last couple of years. “One of them, Rig 4 [an HH-220], has been a consistent top-five performer, averaging well over 600 ft per day, and over 700 ft per day in two quarters. The others, under different drilling conditions, have been averaging well over 500 ft per day,” said Delao. He says that the rig is performing as it was intended, and has drilled some very long laterals, up to 5,000 ft, in the Barnett without a hitch.

As for the environmental aspects, Delao says, “We have not put the quietness of the rig to full use, since we have been drilling more in industrial areas, but the rig is remarkably quiet. The low profile and small footprint have been noted, as you have to be really close to the rig to know it’s there.” The low profile is due to the fact that the rig pulls singles of Range 3 (45 ft) drill pipe. The low noise is due to soundproofing/baffling, the lack of drawworks’ squeaky brakes, and less clanging of pipes.

DISADVANTAGES OF THE RIG

In a sense, there are two disadvantages to the rig: It’s different and it’s made in Italy. The fact that it’s Italian made is only a consideration if you are very distant from Italy and you need a particular part. This has only rarely been a problem in the Barnett so far. Perhaps Drillmec America has some parts on hand.

The uniqueness of the rig might create a learning curve that takes time to overcome. However, according to one superintendent, “If they [rig hands] are sort of green, I’m not sure that the learning would matter, since it’s an automated rig.” The super continued, “The bigger problem is just getting, training and keeping hands, and one that every operator around here struggles with.” He then added, “In terms of NPT [non-productive time], I’d say that the rig gets its fair share compared to any other rig.”

When asked how hard it is to find and keep personnel, Chesapeake’s Delao said, “Not any worse than anywhere else, but the fact that you only need a three-man drilling crew lessens the pressure of finding and keeping good help.” Actually, Chesapeake has a four-man crew. That’s because Mountain Drilling often supplies an extra hand at its expense for training purposes, so it can stay ahead of the need-for-personnel curve.

The only disadvantages that Delao found were tripping time and rig transfer time. Because it pulls singles, tripping time should be longer. “Tripping time probably is a little longer, but in the hands of a good driller, the steadiness brought by automation probably makes the rig comparable to a conventional rig pulling doubles.” It has not shown up on annual rig efficiency data.

The biggest drawback is the time spent in rig up/down and transport. Delao says that Chesapeake allows five days for a typical move of 20 mi or so. The rigs are able to be moved in that timeframe. However, Delao continues, “We have other rigs that get moved in three to four days, so that’s an area we’d like to see improved.” When asked why the packaged rig takes an extra day to move, he said, “I’m not sure; maybe it’s the need to level the carousel carefully. Otherwise the automated pipe handling won’t function properly.”

Delao adds, “We have a number of pad drilling sites, where we drill three to six wells at a time. In these cases, we skid the rig, which takes the same amount of time as it does for any other rig.”

SUMMARY

Clearly, the environmental aspects and their size and capability make these rigs well suited for drilling in the Barnett Shale. Although these rigs can be moved in a reasonable timeframe, there’s room for improvement, as the competition is fierce in this respect. Time spent in rig moves as a function of overall time spent increases as ROP and hole-drilling time decreases. Operators and drilling contractors understandably want this to improve as well.

Overall, it looks like these rigs have secured a place in the market where their characteristics can be put to best use.

|