New products

Vol. 229 No. 6 Trailer-mounted sucker rod unit

Trailer-mounted sucker rod unit

Pump and Coiled Tubing of Fort Worth has developed a trailer-mounted service unit to transport and run the new continuous sucker rod from Fibercom. The unit includes a reel, a crane, a 500-gal. water tank to kill the well and an injector. The trailer is designed so that two men can change out a downhole pump without a work-over unit, once the continuous rod has been run in the well. At only 0.2 ppf, the continuous rod’s ultra-light weight lets operators use Fiberod’s new ECO2 Pumping Unit, which is so efficient that a 3,500-ft well pumping 8-10 bpd can run on less than 1 hp, even using solar power. The Continuous Sucker Rod is used primarily to dewater gas wells and for stripper wells.

Schlumberger and British Telecom have launched the first public wireless broadband service for offshore and remote oil and gas drilling rigs and production platforms. This allows offshore workers to communicate using email, instant messaging and web cam. The service, installed by Schlumberger Information Solutions (SIS), has been operational on the Byford Dolphin rig in the North Sea during a three-month trial. Wireless connectivity is provided over the rig’s main satellite link. The Wi-Fi service allows the 100+ workers to use wirelessly enabled laptops and PDAs, throughout the rig accommodation area, and to access the internet as they would from any BT Openzone hotspot onshore.

Pneumatic torque wrench TorcUP has released the Raptor, a pneumatic wrench with continuous and repeatable torque and an accuracy of ±5%, from 120 to 6,000 ft-lb. The wrench comes in five sizes from the RP-500 to the RP-6000, and has gear technology that creates greater durability, lower operational temperatures and increased efficiency. Unlike other pneumatics that allow water into the body of the wrench, which leads to rust, friction and tool failure, the Raptor has a sealed housing and ergonomic grip for comfort and safe operation. The wrench also features a custom-designed motor for the heavy industrial sector designed to work specifically in industrial torque applications.

Vibration transmitter Emerson Process Management has introduced the CSI 9330 Vibration Transmitter to continuously monitor critical rotating machinery for early detection of developing mechanical issues. The transmitter can be deployed on any asset, but is typically installed on motor-fan, motor-pump, motor-compressor and cooling tower applications. Once installed, it converts the analog output of an ICP accelerometer into a 4-20-mA signal, proportional to monitored vibration, and also delivers PeakVue measurements, which provide additional insight into the condition of rotating element bearings and gear boxes. The vibration information is transmitted to any plant’s PLC, SCADA or control system. When used with Emerson’s CSI 2130 Machinery Health Monitor, the CSI 9330 data is passed to AMS Suite: Machinery Health Manager, giving maintenance personnel early warning of any impending issues. In addition, the CSI 9330 supplements portable route-based data collection systems by providing the ability to access the raw vibration signal, enabling the user to perform advanced vibration analysis.

Aluminum helideck The Astech enhanced-safety aluminum helideck, designed by Zentech Inc., features an automatic fire-suppression system to ensure safer takeoffs and landings. The helideck system, manufactured by Aluminium Offshore Pty. Ltd., has been approved by ABS, DNV, BV, Lloyds and USCG. This and related models have already been installed on more than 200 offshore structures and vessels worldwide. The helideck includes a parking and landing area capable of accommodating two helicopters simultaneously.

Multiphase metering for heavy oil and bitumen Schlumberger announced the first ever application of multiphase flowmetering technology for Steam-Assisted Gravity Drainage (SAGD) wells. Because of extreme operating conditions such as high temperatures, unpredictable emulsion properties and a fourth phase-steam-this type of flow monitoring was not possible with conventional technology in thermal heavy oil operations. The multiphase flowmeter uses Vx technology to measure the flowrate of each phase from the wellhead without the need for lengthy separation tests. Vx technology is available in the Schlumberger PhaseTester portable multiphase well-testing equipment or PhaseWatcher fixed multiphase well production-monitoring equipment. The technology enables better understanding of the production dynamics of SAGD wells operated with high-temperature electric submersible pumps.

Landmark is introducing a parallel storage system for processing seismic data more quickly. The technology is a result of a strategic-development agreement between Landmark and Panasas Inc., a specialist in parallel storage solutions. The agreement adds Panasas ActiveStor storage clusters to Landmark’s portfolio of optimized computing solutions for seismic processing. Conventional storage technologies often can’t keep pace with the parallel processing functions required for seismic processing jobs, creating an input/output bottleneck. Panasas ActiveStor parallel storage clusters, which include the company’s PanFS parallel file system, eliminate these bottlenecks, leading to significantly improved application performance, linear scalability and higher overall utilization of compute clusters. The parallel storage clusters are especially valuable in seismic processing environments because they can scale easily and quickly without disruption. Storage clusters increase overall processing speed as customers add capacity to their infrastructures. Visualization control center Barco has introduced its XDS Control Center software suite. Compatible with Barco projectors, display systems and flat panels, it creates a widescreen Windows desktop on which users can control all sources simultaneously with mouse and keyboard. The XDS Control Center software suite is multi-windowing display management software that offers end users easy data sharing and collaboration. By allowing multiple sources on screen simultaneously, in fully reconfigurable windows, it increases the pace and quality of decision making and cross-analysis in team collaboration. It also includes modules that enable remote desktop sharing and video-conferencing control, so that a display system becomes the heart of network-based decision making. When used with the new XDC-3000 display system, a single-projector, 10-megapixel projection system using high-contrast LCoS technology, it allows up to 10 sources onscreen at the same time, and renders critical details faithfully in large spreadsheets or visual data files. Its high resolution and networking capabilities make it well-suited for life-size video conferencing. The software can also be installed on the Galaxy NH-12 projector, the world’s first 1080p HD, three-chip DLP system that can project both 2D and 3D stereo images at the same time with a light output of 12,000 lumens. The system is aimed primarily at team collaboration rooms or auditoriums. The Galaxy NH-12 features native multi-channel optimizations that make it easy to integrate into display systems of any size, and boasts a newly designed system architecture that gives it a 60% longer lifetime compared with similar three-chip DLP projectors.

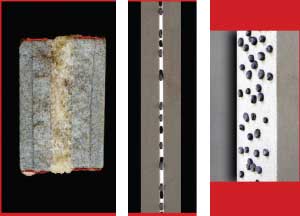

Stimulation methods reduce costs and requirement for freshwater

Halliburton has developed four complementary fracture stimulation technologies to help reduce production cost per barrel of oil equivalent and reduce the use of freshwater in oil field operations. They are OmegaFrac fluid, MonoProp proppant, the ADP blender and the Mimic fluid-measuring device. OmegaFrac fluid is based on a biopolymer that provides easy cleanup to maximize retained conductivity. It is the first frac fluid to practically and economically blend with field-produced brine and effectively suspend and deliver proppant into the fracture, eliminating the need to use potable water without compromising fluid qualities. The new fracturing solution consistently achieves a partial monolayer, or the expansive distribution of propping particulates throughout the fracture. The new MonoProp proppant offers an improvement over existing proppants by achieving a partial monolayer of deformable polymer alloy particles to maintain adequate fracture width without creating flow impediments. This allows unrestricted fluid flow of hydrocarbon from the formation through the fracture to the wellbore. On the environmental front, the ADP blender mixes fracturing fluids from a dry-polymer base rather than a hydrocarbon-based concentrate, while the Mimic proppant transport measuring device directly measures the ability of the fracturing fluid to transport the propping agent under specific downhole conditions. Previously, this measurement could only be inferred from the viscosity of the fluid. |

|||||||||||||||||

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)