New products

Vol. 229 No. 6 Multiple wellbores from a single location

Multiple wellbores from a single location

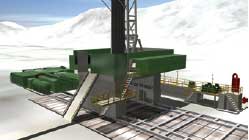

Grey Wolf Inc. has introduced a new fit-for-purpose drilling system, PaDSRig (Production and Drilling System), specifically designed for drilling multiple wellbores from a single pad location. Pad drilling minimizes environmental impact because it allows multiple-well access to larger areas and targets beneath sensitive surface environments such as lakes, towns, national forests, parks and wildlife areas. Combined with directional drilling techniques, multiple-well pad drilling can reduce initial habitat disturbance by as much as two-thirds or more. Engineered and manufactured in Houston by IDM Group, the drilling system incorporates IDM’s QuickSkid pad drilling technology, which features the ability for the rig to skid on a rail track in single- or bi-directional planes from the initial well to other producing wells on the pad. The PaDSRig 109 has a drilling depth capacity of 18,000 ft. The drilling structure can skid up to 140 ft in one direction and 10 ft in another direction from the initial well location to allow simultaneous drilling and production operations. AC technology enhances drilling control and improves fuel efficiency. It features a 28-ft-high drilling floor, 375-ton block and 375-ton hook load rating, and is operable in harsh environments down to -20°C.

Vector drive Wood Group ESP has developed the new Vector VII drive, designed for oilfield pumping applications. It has a number of features not available on most drives, such as an operator control panel with a large, high-resolution, full-color-graphics display that is easy to read in bright light. Its software integrates operating information, downhole well parameters and graphical data into a common display, eliminating the need to scroll through several screens. A digital circular ammeter is displayed on the operator panel, eliminating the need for a mechanical circular ammeter for chart recording. Some 20 operating parameters are periodically sampled and stored in memory, and can be shown graphically on the operator panel or downloaded for analysis. Remote user interface, monitoring and control functions are also supported. The Vector VII is provided in a Nema 3R-rated outdoor enclosure, making it suitable for indoor and outdoor use. All electronic components are inside a sealed (Nema 4) section of the drive enclosure, allowing it to operate in temperatures from -40°F to +122°F.

Coiled tubing services Schlumberger announced the release of the ACTive family of live downhole coiled tubing services, which provide interventions to elevate the performance of coiled tubing operations in various well configurations. A ruggedized high-bandwidth fiber optic cable deployed inside the coiled tubing string connects bottomhole sensors with surface monitors and controls, allowing engineers to measure and interpret downhole events in real time. Continuous monitoring provides instantaneous insight and quantitative feedback on the progress of downhole treatments, and alerts to any deviation from the job design. The ACTive portfolio is composed of six services: ACTive Matrix monitors injection rates, downhole pressures and temperatures of matrix treatments to maximize fluid penetration and coverage, enhance diversion and optimize treatment volumes; ACTive Cleanout uses differential pressure readings to avoid formation damage and minimize the number of trips and operating time, while ensuring thorough removal of fill; ACTive Perf achieves accurate depth control and target coverage in a single run while controlling hydrostatic balance to minimize formation damage; ACTive Isolation ensures efficient, on-depth setting of isolation devices in a single run, controlling differential pressure across the sealing elements to ensure their integrity; ACTive Lift improves the efficiency and results of nitrogen lift jobs by continuous monitoring and balancing of wellbore pressure while avoiding solids production; and ACTive Profiling enhances all ACTive services by including distributed temperature surveying (DTS) to provide a 3D time/temperature profile across the entire well to monitor performance.

Meter for mass flow measurement Krohne Inc. has introduced the Optimass 2000, a large-diameter Coriolis mass flowmeter for accurate and repeatable bulk measurement in the oil industry. It uses the twin-straight-tube design of the OPTIMASS 1000, and is available in three sizes: 4 in., 6 in. and 10 in. The meter’s wetted parts are constructed of NACE-compliant duplex stainless steel (ANS 31803), and it is available with flange ratings up to 1,500 lb, in flange sizes from 4 in. to 12 in. The meter is CRN approved and can handle process pressures to 2,200 psig with a stainless steel outer cylinder that can handle burst pressures over 1,500 psi. Flowrates from 250 to 4,400 lb/min. can be handled, with a measuring accuracy of 0.1%. The meter features the MFC300 converter, and is available in a compact or remote version. All signal processing is carried out by the MFC300, which converts the meter output to a MODBUS RTU communications signal. All calibration data is secured with redundant memory.

Web-based operating environment Landmark has released a new version of its AssetObserverT web-based operating environment, built on the IncuityEMIT platform. AssetObserver allows production experts to access and integrate data from a range of sources and monitor complete workflows and assets in real time. The new version addresses a critical need for comprehensive data access and holistic asset analysis in field production. The web-based operating environment frees production engineers to focus on analyzing data and develop smarter production plans, rather than searching for and formatting data. The software is a key component of the company’s DecisionSpace for ProductionT suite, an end-to-end production solution that offers integrated data access, data management, workflow construction, visualization, collaboration and real-time optimization.

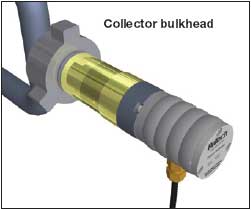

Wireline tools for coiled tubing AnTech Ltd. has announced the latest additions to its range of “Wireline in Coiled Tubing” tools: the new collector bulkhead and a 27/8-in. logging head featuring seven conductors. The collector bulkhead provides an improved means of connecting wireline to surface. Installation and connection of the wireline are simplified-the electrical connections are situated on rails so that one person can carry out installation and maintenance. The new bulkhead is available in both single- and seven-conductor configurations to suit customer requirements, including Atex options. The addition of a 27/8-in. logging head to the 111/16-in. and 21/8-in. versions provides customers with a seven-conductor option for running video or openhole tools. With their modular design, the tools can be manufactured to meet customer-specified connections and cable sizes. The 21/8-in. and 27/8-in. tools are available with a mechanical release featuring precision shear pins or an electrical release for controlled release. The logging heads can also be used in highly deviated and horizontal wells where wireline is not an option. Suitable applications are open and cased-hole logging and perforating.

Electromagnetic Geoservices ASA (EMGS) announced the launch of Clearplay, the first fully integrated EM system, providing seamless, end-to-end EM services and products in support of hydrocarbon exploration. The Clearplay portfolio consists of three distinct services-Clearplay Find, Clearplay Test and Clearplay Evaluate. Fundamental to the system is its ability to reveal information that is intimately linked to the presence of hydrocarbons. Integrating Clearplay with the traditional exploration workflow enables a clearer and more complete understanding of the subsurface. Clearplay Find involves towing a high-power EM source over a course grid of receivers, 2-4 km apart, and the subsequent, rapid processing of data onboard the survey vessel. It is employed in early-stage exploration, pre- or post-licensing, but can also be used to re-explore mature areas. Clearplay Test provides rapid, more accurate ranking of prospects in offshore locations, reducing the likelihood of dry wells. Typically, a prospect will be targeted by towing the EM source over receivers placed in one or more lines, or a grid, 1-2 km apart. Operators are able to achieve a better discovery rate, with the same or fewer resources, than when using traditional methods alone. Clearplay Evaluate improves certainty and efficiency in appraisal- and development-phase decision making, and improves the assessment of a reservoir’s potential following successful discovery well drilling. Typically the data is acquired by towing the EM source over and between the lines of a dense grid of receivers, 0.5-1.5 km apart. The quantity and quality of the information this generates, including 3D azimuthal data, enables the most sophisticated data processing visualizations to be used and increases the accuracy of the results. When integrated with information from other sources, such as 3D seismic, it can significantly improve the speed and accuracy of prospect appraisal, giving a more informed assessment of hydrocarbon volumes and distribution within a prospect.

Tank level switch The NuTec LS2000 Level Switch from Fluid Components International (FCI) provides reliable level monitoring and interface control in industries that require precise measurement, low maintenance, long life and low instrument cost. The LS2000 is designed for two-wire, 4-20-mA loop power, which allows it to serve as a drop-in replacement for other two-wire mechanical float and paddle switches without any wiring modifications during retrofit projects. It is also available for 115/230-V AC or 24-V DC input power and a 6A relay output. The switch features a no-moving-parts thermal mass flow sensor constructed with either 304/305 stainless steel or 316L all-welded stainless steel with wetted surfaces for rugged environments. In its top-mount configuration, the switch measures level within ±0.25 in. from its element tip. The side-mount configuration is accurate to ±0.125. It is fully temperature compensated for environment swings of up to 100°F to provide accuracy and stability under harsh conditions. The instrument is also highly responsive, sensing dry-to-wet conditions in less than 2 sec., wet-to-dry in less than 5 sec. and wet-to-wet interface in less than 10 sec.

|

|||||||||||||||

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)