Optical based software techniques for real-time analysis of produced water

Aspect ratio is not always effective in discriminating oil particles from other solids, but a combination of optical parameters gets the job done.

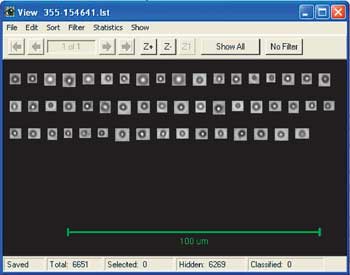

PRODUCED WATER REPORTOptical based software techniques for real-time analysis of produced waterAspect ratio is not always an effective means of discriminating oil particles from other solids. A combination of optical parameters gets the job done.Jonathan M. Villeneuve, Fluid Imaging Technologies, Inc., Yarmouth, Maine Optical instrumentation has many benefits over other technologies for analysis of particles in produced water. The technique sets itself apart from other rapid particle-characterization methods because of its morphological advantages. In addition to measuring suspended oil-in-water concentrations, optical techniques coupled with advanced data analysis and pattern matching can be used to effectively distinguish, and then classify, two particles of identical size and shape. This article illustrates the efficacy of various imaging techniques for use in real-time characterization and quality assurance of produced water. OIL DROPLETS IN PRODUCED WATER Assuming relative velocities are low enough, oil suspended in water will take on a spherical shape. When viewed using two-dimensional microscopic means, the droplets appear as circles of the same diameter. Due to differences in refraction indices of both oil and water, the light is focused and appears bright in the middle with a dark ring around the edge, Fig. 1. These small circles can be measured and counted to obtain oil-in-water concentrations and droplet size distributions.

Non-oil particles in produced water. Various other particles can be present in produced water, including iron sulfide, iron oxide, sand, silt or mud, bacteria and magnitite. These particles vary greatly in size, but they can be the same size as the oil droplets one is measuring. Techniques like turbidity and laser diffraction make differentiating these solids from oil droplets difficult, rendering them less effective in determining oil concentrations in water. Aspect ratio as a discriminator. The aspect ratio is defined as the quotient of an object’s width and length. Most imaging particle analyzers use aspect ratio as the primary factor for discriminating between oil and solids. Because oil suspended in water takes on a spherical shape, its aspect ratio is theoretically 1. However, due to slight inaccuracies in the imaging and analysis process, single oil droplets often have an aspect ratio as low as 0.70-0.75. Conversely, the shape of non-oil solids varies greatly. If a particle’s aspect ratio is less than 0.70-0.75, then that “long” particle is identified as a non-oil solid. Figure 2 shows iron sulfide particles viewed through an automated fluid-imaging particle analyzer. The particle aspect ratios are all less than 0.60. It appears that the “round vs. long” rule would be a good indicator in this case. But is aspect ratio always a good indicator of whether a particle is an oil droplet?

Agglomerates. Whether naturally occurring or caused by a chemical additive, oil droplets sometimes connect to form an agglomeration. These agglomerates may contain two or more oil droplets of similar or different diameter, and the shape is often “long” with a low aspect ratio, Fig. 3. Take the simple case of an agglomeration of two side-by-side oil droplets having identical diameters (D). The width of this particle would be twice the diameter, and the length would be D, making the aspect ratio D/2D = 0.5. The “round vs. long” rule would classify these agglomerates incorrectly as solids, thus leading to an inaccurate oil and solids concentration (i.e., ppm).

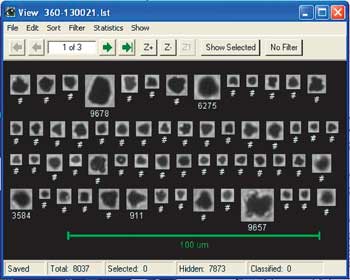

Round solids. Just as oil agglomerates can be misidentified when aspect ratio is the only discriminating factor used, round solids can present similar issues. Figures 4 and 5 show solids with an aspect ratio above 0.70. Again, the “round vs. long” rule would classify these solids incorrectly as oil, and therefore the oil and solids concentration would be faulty.

PATTERN MATCHING ALGORITHMS If aspect ratio is not the solution, then what is? Certain imaging systems measure upwards of 20 different parameters of the particle image they capture, and the number continues to grow as technology improves, see Table 1. Using a combination of these parameters, coupled with complex weighting formulas, accurate classifications of particles can be achieved. These non-linear algorithms highlight the more significant features of the particle while diminishing those which are less important.

Once libraries of different groups of particles are created, they can be used to automatically discriminate and identify other particles in a sample; e.g., libraries of agglomerated oil particles will be used to identify agglomerated oil in the sample. Not only are accurate oil and solid concentrations possible, but certain solids in the water can be distinguished from one another. CONCLUSION Proper particle characterization of produced water is facilitated by advanced pattern matching. Effective pattern matching leads to better particle discrimination, which leads to more accurate concentration measurements and improved produced water component characterization. This will allow for further process understanding.

|

||||||||||||||||||||||||||||||||||||||||

- What's new in production (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Dallas Fed: E&P activity essentially unchanged; optimism wanes as uncertainty jumps (January 2024)

- Enhancing preparedness: The critical role of well control system surveys (December 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)