RIG FLOOR EQUIPMENT

Easy offline capabilities for conventional rigs

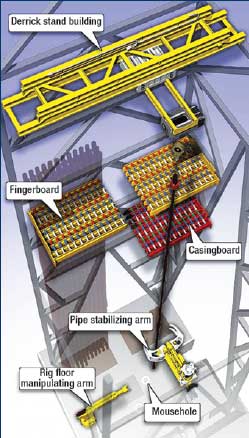

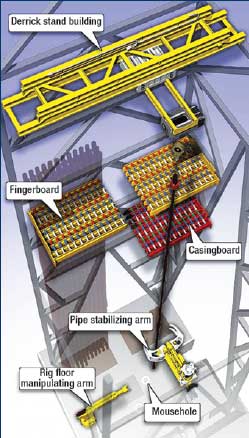

The Derrick Stand Building (DSB) System developed by ODS International can be retrofitted to virtually any rig mast or derrick configuration, and provides the ability to build stands of drill pipe, drill collars and casing independent of well-center activities. In so doing, the rig operator avoids the need to pick up or lay down tubulars with the main hook, resulting in significant time savings at the beginning or end of the well, or any other time when pipe must be run from the deck. The system can also be used as a reliable backup to an existing column pipe-racking system.

“The DSB System provides immediate efficiency gains without the cost or critical path failure impact of traditional column pipe-racking systems,” states Richard Hancock, president of ODS International.

|

The DSB system can also be used as a backup to existing column-pipe racking systems.

|

|

The system consists of a jib and trolley arrangement that can move independently in both X and Y directions, allowing the system to rack pipe in any fingerboard arrangement, either inward or outward facing. For example drilling a 22,000 ft well with only 17,000 ft of pipe storage in the derrick no longer requires 5,000 ft of pipe to be made up in singles from the deck when you trip the bit, eliminating 67% of connections at well center. In a similar fashion, casing can be made up in doubles and racked in the derrick using the DSB rather than being run in singles from the deck. This potentially eliminates 50% of connections at well center and saves time by running casing directly from the derrick.

Likewise the Bottom Hole Assembly (BHA) for the next hole section can be made up, racked back and tested prior to pulling the existing assembly. This capability not only eliminates 50 to 80% of connections at well center but also saves significant time in BHA testing, configuration and data retrieval. The DSB sits above the existing fingerboards and allows conventional operations to take place at times when it is not needed. Furthermore, the design can be used as a vertical winch placed directly above rig-floor tools to transport them safely and securely without disruption. When combined with the company’s Pipe Stabilizing Arm (PSA-322), the DSB provides the ideal casing running system and a clear advantage for conventional rig operations.

|