PRODUCTION

TECHNOLOGY

ESP deployed via riser to lift subsea well

An

innovative solution to slugging and liquid loading in the Gulf

of Mexico increased well production 150%, and may increase overall

recovery 35%.

David Cocciolone and Mike

Parker*, Anadarko Petroleum Corporation; Tiffany Pitts and

Mark Ohl, Baker Hughes Centrilift

The No. 1 well in East Breaks Block 690

is a 4½-mi subsea tieback

to Anadarko’s Nansen spar in the Western Gulf of Mexico. The

well produced 1.7 million bbl oil before pressure depletion caused

slugging and frequent liquid loading in the riser and the subsea flowline

network. Loading of the riser occurred at a 5-10% watercut, leaving

significant reserves in the ground. As such, a viable form of artificial

lift was needed.

In February 2007, an Electrical Submersible

Pump (ESP) was installed in the subsea riser leading to EB 690 No.

1. A Hydraulic WorkOver (HWO) unit was rigged up on the Nansen spar,

and the pump was deployed on 2 7/8-in. tubing through the 6-in. riser.

With the ESP allowing for a lower pressure at the riser base, multiple

benefits have been realized, including the elimination of slugging,

higher fluid rates and the lowering of the reservoir abandonment pressure.

Production increased to 3,500 bopd after installation from 1,400 bopd

(when not loaded up). Based on reserves produced to date, it is estimated

that the ESP will increase ultimate recovery by 35%.

BACKGROUND

East Breaks 690 No. 1, at a water depth

of 4,200 ft, is a subsea tieback located 4½ mi south of the

Anadarko-operated Nansen spar, in which Devon Energy holds 50% interest,

Table 1. Positioned about 118 mi south of Galveston in 3,640 ft of

water, the Nansen spar produces from nine dry-tree wells and six

subsea wells. While all of the dry-tree wells are capable of gas

lift, none of the subsea wells has any form of artificial lift installed.

Some of the subsea wells have been producing for over 5 yr, and pressure

depletion and increasing water production have contributed to decreased

oil production. Therefore, engineering solutions have been sought

to prolong the life of these subsea tiebacks.

| TABLE

1. Basic well and pump information for East Breaks

690 No. 1 |

|

|

EB 690 No. 1 is part of a three-well subsea

infrastructure, connected via a piggable flowloop to the two other

subsea wells, Fig. 1. The flowloop has a 5 5/8-in. ID, the same as

the flexible riser tied back to the spar. Both wells on the other

side of the flowloop are shut in due to pressure depletion or high

watercut, but EB 690 No. 1 was still producing 1,100-1,800

bopd. Hydrates have been a major concern throughout the life of the

subject well, and at one point a hydrate formed in the flowline and

had to be dissociated by depressurizing the flowline with nitrogen.

|

Fig.

1. Nansen subsea layout. |

|

Slugging was another issue in the well, caused by a combination of

liquid loading in the 6-in. (55/8-in. ID) riser, low reservoir pressure

and low flowrates. Furthermore, the well became increasingly difficult

to bring online after a shut-in, and at times it would load up during

normal operations. The need for constant monitoring, along with the

lack of sustainable production, led to a review of artificial lift

options.

DEVELOPMENT OPTIONS

One option considered to address slugging

was to place a 2-in. velocity string in the 6-in. riser. This would

mitigate slugging, but would be ineffective in unloading the well,

which was a concern as pressure depletion continued. Gas lift was

proposed to help unload the well, but no means of gas lift were in

place in the wellbore, flowline or riser. One option available was

to send gas down a ¾-in. line

in the existing umbilical to the EB 690 No. 1 subsea Pipe Line End

Termination (PLET) just downstream of the tree. It was determined that

a maximum of 1 MMcfd could be sent down the line; unfortunately, such

a small volume would be insufficient to unload the well and would not

provide a long-term artificial lift benefit.

However, lowering the riser hydrostatic pressure as much as possible

was still a priority, and an ESP was considered a viable option. By

boosting pressure at its installation point, an ESP could lower the

intake pressure at that point and prevent slugging. Also, the hydrate

risk would be reduced by having steady flow in the pipeline network.

Furthermore, the abandonment pressure would also drop, allowing additional

recoverable reserves to be produced.

When considering ESP (or any other artificial

lift) proposals, two options were available: to run the ESP from

the spar and install it in the riser to boost fluid from near the

seafloor, or to run the ESP in the subsea well and hook up power

to it from the spar. Installation costs to run the ESP in the riser

included the spread rate of an HWO-about

US$25,000 a day. To run the ESP in the subsea well would require a

floating intervention vessel, running up to $500,000 a day. Furthermore,

supplying power to the ESP in the subsea well would cost millions of

additional dollars. All in all, subsea intervention would have likely

cost about $30-40 million vs. about $2.5 million to run the ESP

in the riser.

Given the reserve estimates of the existing completion, installing

an ESP at the base of the riser was found to be the best economical

option to mitigate slugging, prevent load-up, produce at higher rates

and increase ultimate recovery. The only question remaining was whether

the project was feasible to pursue on the Nansen spar.

PROJECT DESIGN

The first step was to ensure adequate access to the riser. Fortunately,

the risers on Nansen were designed to be accessible via coiled tubing

if for some reason a washout of the flowline was required. The necessary

power supply was available on the spar, which has two generators capable

of producing 5,000 kW. At the time, only 2,000 kW were in use, leaving

plenty of power to run a pump. Space on the platform was then found

to accommodate the drive and transformers. Running an ESP down the

riser was judged to be feasible, so design work proceeded.

Pump design. The well

had a low drawdown, a high productivity index, was gravel packed

and was capable of producing greater volumes if a larger drawdown

could be achieved. Modeling of the wellbore, flowline and riser showed

that a pump with the maximum fluid throughput would be required.

Baker Hughes’ Centrilift

400-series P60SXD pump, with a high-volume pump stage and capability

of landing in a 5 5/8-in. ID riser, was selected.

Downhole and surface issues. One potential

problem for the pump was the well’s high gas fraction at the riser base. Every stock tank

bbl of oil was accompanied by 1,000 ft3 gas, and gas fraction at the

pump intake was 46%, close to the pump’s handling capacity at

the design intake pressures.

Fortunately, the existing setup allowed

for options to reduce the gas fraction at the intake. With the ESP

run on tubing inside the existing production path (i.e., the 6-in.

riser), gas could be separated before it entered the pump both by

natural separation and by the inclusion of a vortex gas separator

in the pump string. The gas could then be sent up the riser/tubing

annulus to production. The liquids would be sent through the pump,

up the tubing and into the existing production manifold. In order

to direct gas on the backside to various production vessels, a new

manifold on the Nansen spar would have to be constructed. Pump production

(through tubing), annular production or both could be sent through

a test separator, which would make it possible to a) determine how

much gas is entering the pump and b) monitor the seperator’s

efficiency.

With downhole separation sending gas to the annulus, special consideration

would need to be taken regarding materials. Though the gas only had

a CO2 molar fraction of 0.2%, the possibility of 4 MMcfgd traveling

up the backside meant that any equipment run in the riser would need

to be CO2-corrosion resistant. Furthermore, the riser was constructed

of 304L stainless steel, and material compatibility was a concern.

Because of these issues, all string components where designated as

stainless steel or equivalent. The tubing would be composed of 13-chrome,

the cable protectors of stainless steel and the ESP housing also of

chrome. Because the integrity of the cable was of particular concern,

it was decided to use a Monel armor to protect the cable and ensure

material compatibility. A lead barrier was also included in the cable

design to reduce the risk of gas intrusion causing a premature electrical

failure in the cable.

Downhole monitoring was also considered an important criterion because

the well was capable of high production rates and because the flowline

had experienced large pressure drops due to hydrates. A Centrilift

Centinel downhole gauge was included to monitor downhole pressure,

temperature and motor temperature. The ability to monitor the pressure

drop between the subsea wellhead and the pump intake (near the base

of the riser) would help in monitoring pipeline performance over the

life of the well. Action, such as increasing the methanol injection

rate, could then be taken immediately if any abnormal pipeline pressure

drop was detected.

Other technical challenges to installation remained. The riser in

which the ESP was to run had no means of hanging tubing, and therefore

a wellhead would need to be fabricated and landed above the riser.

The wellhead would serve two purposes: as a location to land the tubing

hanger and to send the annular production to a new manifold. The wellhead

had to be custom made to land on the adapter flange below and tie into

the shutdown valves above.

ESP string test. The flexible riser in

which the ESP was placed moves somewhat in rough weather. However,

with the ESP and tubing landed on a wellhead attached to the spar,

movement would be in the same line, reducing vibration between the

ESP assembly and the riser. Nonetheless, the operator wanted to ensure

that the pump would see as little vibration as possible. A string

test would ensure proper fit of all downhole components and verify

the system’s

operation in a downhole environment. The test parameters monitored

were head, flow, skin temperature of each system component and vibration

signature of the system.

All components of the downhole ESP assembly, from the downhole guage

to the pump, were run in a test well. During initial testing, vibrations

of frequencies above recommended levels were observed in several components.

Since these frequencies were likely to occur offshore, the components

were disassembled and the critical components were inspected. No visible

or dimensional problems in the shaft, bearings or other components

were found. The ESP was then assembled and re-tested. The resolution

of the vibration instrumentation was increased to further separate

frequency peaks. With the finer resolution, the peaks were identified

as half-speed oil whirl in the journal bearings. An additional test

was run with a higher-viscosity motor oil. This brought the vibration

readings within acceptable limits and still allowed for proper lubrication

properties at design conditions.

Modeling the well network in existing conditions was nearly impossible

due to dips in the flowline and slugging. It was quickly realized that

the well would need many adjustments to optimize flow upon startup.

Due to the 5-mi length of the flowline, the history of gas slugging

and declining bottomhole pressure, a Variable Speed Drive (VSD) would

be necessary for control. A VSD was requested, and although the spar

has limited deck space, adequate room was found to securely place the

drive, transformers, annulus manifold and wellhead.

ESP INSTALLATION

Each of the three subsea wells tied into the flowline and riser has

three isolation valves at the tree, as well as a surface-controlled

subsurface safety valve. The ability to isolate the riser from well

pressure allowed easy access to the riser and flowline and greatly

simplified installation of the ESP. To ensure that the riser was safe

to access during installation, the flowline would be displaced with

10.4-ppg CaCl2 to dissociate any potential gas pockets that remained

and to clean any paraffin or other buildup.

A method of ESP installation still had

to be chosen. If jointed tubing was run, then either a platform rig

or a Hydraulic WorkOver (HWO) unit would be needed. Running the ESP

via coiled tubing was another option, but 2 7/8-in. chrome coiled

tubing was not available at the time. In the end, an HWO was preferred,

as it is quick and inexpensive to mobilize. Furthermore, no pressure

control, and thus no BOPs, would be needed, saving on cost and rig-up

time. Although an HWO does not run tubing as quickly as a rig, the

short length of pipe to be run minimized this factor.

After the flowline was displaced with fluid, the flowline valves above

the riser tieback were nippled down and the wellhead fabricated for

the job was made up to the existing double-studded adapter, Fig. 2.

This is where the tubing hanger would be landed and cable penetrations

made.

|

Fig.

2. Valves above the riser tieback (a) were

removed, and the new wellhead was flanged up (b) to

the existing double-studded adapter to facilitate the

tubing hanger and cable penetrations. |

|

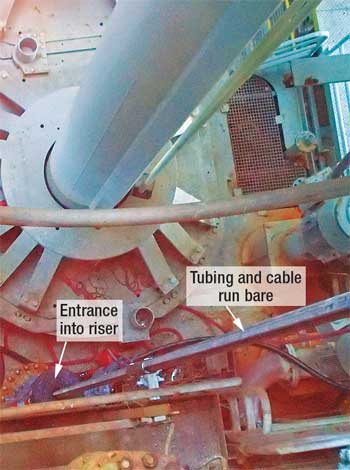

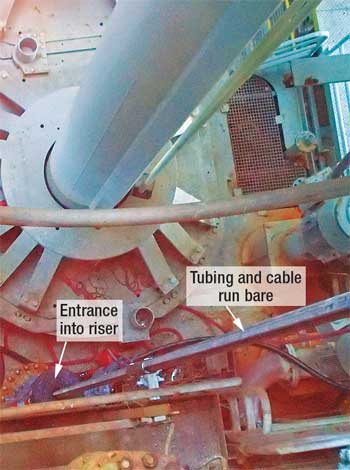

Because no pressure control was required, the ESP and tubing were

run with no riser above the wellhead, Fig. 3. A bell nipple was manufactured

to allow diversion of fluid to a tank in case any was displaced out

of the flowline riser when running the ESP in the hole. The ESP assembly

was guided into the bell nipple above the wellhead. Simultaneously,

the cable was being spooled onto the pipe and clamped onto the tubing

at the access window. It took slightly less than 24 hr to run 3,124

ft of tubing and the downhole components with cable and clamps. To

facilitate fluid flow up the annulus, no downhole packer was set and

the assembly was not rigidly connected to the riser downhole. All the

weight of the tubing and pump components was distributed at the wellhead.

The tubing hanger was run through the HWO as well, and all penetrations

through the hanger were made at the access window, Fig. 4. The hanger

was then landed and the tubing bonnet installed with the penetrator

wires running through, completing the HWO.

|

Fig.

3. Tubing and cable were run riserless through

the wellbay into the EB 690 No. 1 riser. |

|

|

Fig.

4. All penetrations through the tubing hanger

were made at the access window. |

|

After the ESP was RIH, the VSD was picked up and placed in the motor

control center. Laying of cable trays and pulling of cable having been

previously completed, wiring was now terminated into the junction box,

transformers and VSD. Together with the Human-Machine Interface (HMI)

programming, this took a few days.

Drive control. The operator desired full

control of the ESP from the HMI interface. This required having a

programmer on board to program the control functions into Wonderware,

Anadarko’s

proprietary HMI system. From a computer terminal, the operator can

start or stop the pump and adjust its frequency with a mouse click.

The downhole gauge relays the intake pressure, intake temperature,

motor temperature and other subsea data to the same computer terminal.

This data can be trended with the touch of a button to better monitor

and troubleshoot.

Unloading CaCl2. About 900 bbl of 10.4-ppg CaCl2 in the flowline and

riser would need to be displaced before wellbore fluid would reach

surface. The heavy fluid initially gave the pump some difficulty, causing

it to take a long time to speed up to the minimum required frequency.

Once the pump reached that speed, flow was rather erratic, with rates

fluctuating wildly. However, once all the heavy fluid was out of the

system, rates and pressures began to behave as expected.

WELL STARTUP

After the CaCl2 was displaced out of the

line, the pump started to run more easily. When the pump was run

at target frequency, the downhole electrical current was observed

to fluctuate significantly-anywhere

from full load (35 A) to underload conditions. These underload conditions

resulted from slugs of gas moving through the pump, causing it to run

nearly in idle. To alleviate this, the pump was programed to speed

up whenever gas entered the pump (i.e., under low-current conditions).

The increased frequency would allow the pump to do more work, avoiding

extreme underload conditions.

A high-current limit was also programed

in. When fluid would hit the pump, increasing the load to nearly

35 A, frequency would automatically adjust lower to prevent the load

from exceeding 35 A. The frequency never adjusted below 54 Hz-still

sufficient speed to move fluid through the pump. The pump control

continues to be set at a target current, with frequency being adjusted

automatically to maintain a proper load.

After this adjustment was made, EB 690 No. 1 was tested by sending

both the tubing and the annulus production to the test separator. A

12-hr well test resulted in production of 3,931 bopd, 3.9 MMcfgd and

85 bwpd. Liquid dumping from the separator was fairly constant, and

slugging was not a serious problem. One unknown that remained was the

ratio of production through the tubing (pump) to production through

the annulus. To find this value, the tubing production was sent to

the test separator and the annulus production was sent to the Intermediate

Pressure (IP) separator, with both vessels at nearly the same pressure.

This would reveal not only rates from both sides, but also how much

gas was being diverted to the annulus, i.e., the effectiveness of the

gas separator. Results of the test were as follows (adjusted for conditions

at pump intake):

- Oil production through pump:

2,254 bpd

- Gas production through pump:

1.6 MMcfd

- Oil production through annulus:

1,879 bpd

- Gas production through annulus:

1.8 MMcfd

As shown, about 55% of oil is produced through the pump, along with

about 45% of gas production. Surprisingly, a sizable amount of the

fluids are producing up the backside. Though the gas separator is not

separating gas as efficiently as expected, this does not appear to

affect total volumes.

Pressure response. ESP intake pressure

at the base of the riser holds fairly steady at just under 800 psi,

whereas unboosted pressure at this depth was 1,500 psi. This corresponds

to a lower flowing tubing pressure with the ESP than without, Fig.

5. The pressure drop is transferred all the way to the perforations,

and has greatly increased reservoir drawdown-to the point where

the well is slightly choked back in order not to exceed reservoir

voidage guidelines. Flowrates before and after ESP installation can

be seen in Fig. 6.

|

Fig.

5. Flowing Tubing Pressure (FTP) for EB 690

No. 1 is plotted against cumulative oil production.

Linear trends before and after ESP installation are

extended to load-up pressure. |

|

|

Fig.

6. Flowrate for EB 690 No. 1 before and after

ESP installation. |

|

WELL EXPECTATIONS

It is expected that the EB 690 No. 1 will

continue to produce at higher rates due to the reduction of the bottomhole

pressure, resulting in higher drawdown and the mitigation of severe

slugging. It is anticipated that boosting the riser will reduce the

abandonment pressure of the well by 500 psi. Based on historical

well production, a 500-psi abandonment-pressure drop will increase

the well’s estimated ultimate recovery by

about 35%.

FUTURE APPLICATIONS

Anadarko is already looking at future applications for ESP riser lift.

Potential uses for this technology are in subsea tiebacks with no form

of artificial lift previously set up in the following environments:

- Oil wells with gas fraction

at pump low enough for an ESP to handle (downhole separation may

be required)

- Confidence that the watercut

will not rapidly increase with depletion, possibly resulting in unfavorable

economics

- Sufficient power at the facility

to run the pump, as well as adequate room for transformers and the

drive

- A means of accessing the riser

in order to run the ESP

- The riser in sufficient water

depth to provide meaningful pressure boosting.

At the time of this writing, Anadarko has six spars and one TLP in

the deepwater Gulf of Mexico, all with subsea tiebacks. As the wells

become more mature and artificial lift becomes necessary to prolong

field life, riser lift via ESP will be a viable option for many of

these facilities.

CONCLUSIONS

Running an ESP in the riser tied into

the flowline of the EB 690 No. 1 well resulted in immediate benefits.

Production increased by 2,500 bopd (2,900 boepd), slugging was mitigated,

and liquid loading ceased to occur. Long-term benefits will be realized

as well, as EUR is expected to increase by 35% with the lowering

of the abandonment pressure. Overall economics look very sound, with

finding and development cost for this project under $4/boe. With

the success of the ESP installation and results realized, other candidates

will be evaluated as subsea wells continue to mature.

|

THE AUTHORS |

|

David

Cocciolone is a senior completions engineer for

Anadarko and has spent the last three years working as a

production engineer in the deepwater Gulf of Mexico. He started

his career in 2001 with Kerr-McGee Oil and Gas, holding positions

in drilling, reservoir and completions, mostly offshore.

Mr. Cocciolone earned a BS and an MS degree in petroleum

engineering at Texas A&M University, along with a master’s

degree in petroleum economics and management from Institut

Français du Pétrole. |

|

| |

Mike

Parker is Operations-Engineering manager for Crimson Exploration.

Before joining Crimson, he was the Gulf of Mexico production

engineering manager for Anadarko. In this position, Mr. Parker

is responsible for overseeing production engineering for the

company’s nine operated deepwater GOM facilities. He earned

a BS degree in chemical engineering at Purdue University in 1981,

after which he joined Amoco Production Company. Mr. Parker has

spent most of his career working on artificial lift and production

optimization issues in the US and, for seven years, in Jakarta,

Indonesia, for Maxus Energy. While in Jakarta, Mr. Parker was

responsible for managing Maxus’ 450 offshore operated ESP

wells. |

|

| |

Tiffany

Pitts is a strategic account manager for Baker Hughes Centrilift.

Ms. Pitts joined Centrilift in 2005 and has worked as an applications

engineer, project coordinator and tender team manager. She earned

a BS degree in chemical engineering at Auburn University and

an MS degree in neuroscience at the University of Houston. |

|

| |

Mark

Ohl is a senior operations account manager for Baker

Hughes Centrilift. Mr. Ohl has 26 years’ experience in

the petroleum industry, 23 of which have been in the ESP sector.

He joined Centrilift in 1992 and has worked in the major producing

areas of the lower 48 states as well as the GOM. For the last

five years, he has focused on projects in the Continental Shelf

and the deepwater GOM. Mr. Ohl earned a BS in business administration

from Emporia State University in Emporia, Kansas, USA. |

|