|

|

|

By Petroleum Technology Transfer Council |

Seeing a reservoir's character from solution gas

Raman spectroscopy provides early insight into Wyoming coal bed reservoir heterogeneity

Eric Koval, Black Diamond Energy Inc and John Pope, WellDog Inc.

Black Diamond Energy used WellDog's advanced reservoir characterization down-hole spectroscopy to directly analyze heterogeneity in gas content, critical desorption pressure, and required drawdown in the CW coal bed methane field in the Powder River basin. The data revealed surprising heterogeneity in coal seam properties and showed that further development should proceed in a specific direction. In addition, the reservoir's heterogeneity revealed discontinuities in the coal-seam aquifer that guided subsequent dewatering and production strategies.

DOWNHOLE RAMAN SPECTROSCOPY

A number of techniques are available for gas-property characterization of coalbed reservoirs. The traditional method, gas desorption from core sampling, and its low-cost version, gas desorption from cuttings, are both limited in representing the reservoir, since they are highly susceptible to near-wellbore petrology variations. In addition, they are tedious to employ and disrupt the completion and production schedule.

Fortunately, WellDog adapted a downhole Raman spectrometer to analyze coalbed reservoir properties. The spectrometer performs direct, laser-based interrogation of solution gas content in reservoir fluids drawn into the wellbore. The reservoir's effective methane partial pressure (equivalent to the reservoir's critical desorption pressure) is determined, and the gas content and required drawdown can be easily calculated.

Most important, the measurement requires less than a half-day per wellbore and the resulting analysis can be completed in just a few days. This fast turn-around allows operators to characterize their reservoirs and immediately adjust development.

CW FIELD

The CW field lies in the central portion of the Powder River basin within Wyoming. Multiple coal seams converge and diverge within the area, exhibiting the coal's lenticular nature. The coal seam characterized in this study is part of the Big George coal package, commonly called the Cook seam.

Black Diamond used the reservoir characterization service to evaluate and optimize gas content, critical desorption pressure and required drawdown for this coal. The business driver was to guide further development in the Cook seam, as well as to set internal expectations about the field's future production-economics and timing.

The company used the service on 17 field wells, profiling each wellbore fluid's solution gas concentration. Engineers calculated the reservoir's methane partial pressure (i.e., critical desorption pressure) around each wellbore using the solution gas concentration, together with temperature, pressure and conductivity data, collected simultaneously in each wellbore.

The critical desorption pressure was compared to the static reservoir pressure to calculate an initial gas saturation, as well as the drawdown required for gas production. The critical desorption pressure was mapped onto an adsorption isotherm, representative of the average reservoir conditions in the field, in order to calculate the reservoir's gas content around each wellbore.

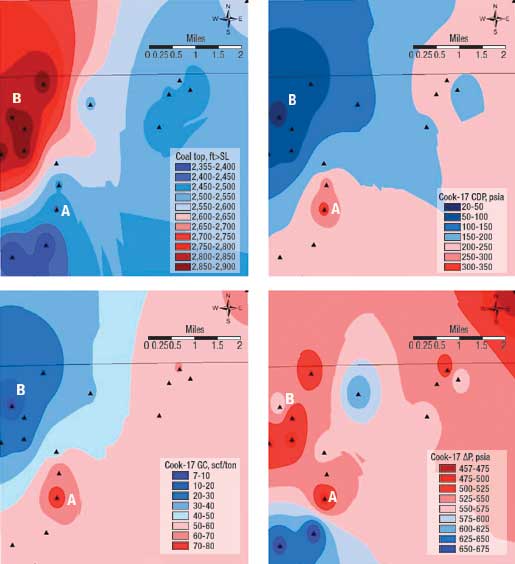

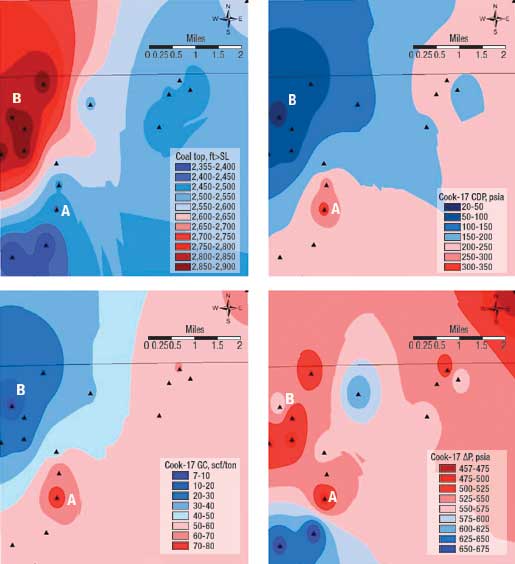

Reservoir characterization results are shown in Figure 1. At upper left, coal top elevations from gamma logs are plotted. The coal depth varies from about 2,400-ft elevation in the southeast to 2,900-ft elevation in the northwest. Conventional wisdom holds that the methane partial pressure and gas content should be higher in the coal portions at greater depths.

|

Fig. 1. The reservoir characterization over CW field includes: (upper left) coal top elevations from gamma logs, (upper right) critical desorption pressure, (lower left) gas content and (lower right) required drawdown.

|

|

At upper right, the field's critical desorption pressure is plotted. In general, most of the gas is located in the deeper portion of this field. However, significant gas is associated with a subsurface feature (Well A) at about 2,450-ft elevation in the southwest. The critical desorption pressure varies from greater than 200 psi in the southeast to less than 50 psi in the northwest. Desorption pressure peaks around Well A at 350 psi.

Likewise, the gas content (lower left) and required drawdown (lower right) distributions in this field show areas of promising economic production and areas that are not acceptable targets. For example, Well A shows both desirable gas content at about 80 scf/ton and some of the most manageable dewatering conditions with a required drawdown of about 500 psi. Conversely, Well B requires a similar drawdown for production, but has gas content below 10 scf/ton.

In a typical coal bed methane field, it is common to observe dramatic variations in gas production across the field. However, coals are commonly continuous and permeable, and operators regularly produce water from wells that do not show gas to reduce the overall pressure in the field. In many cases, this can help increase gas production in adjoining wells.

By examining distribution discontinuities of reservoir properties across this field, it is possible to differentiate between wells that will contribute to overall field drawdown and wells that appear to be hydrologically disconnected from the targeted regions of the field. For CW field, it is unlikely that wells in the northwest will contribute substantially to dewatering the southeast area, where most of the gas resides. As a result, the operator focused the dewatering and production plan on the "sweet spot," avoiding areas of high water production/ low gas production, and decreasing the overall water/ gas production ratio in the field.

Collecting additional data using the service saved over one million dollars compared with traditional core sampling desorption processes. In addition, the data was available in a matter of days, instead of the weeks to months typically required for core desorption and analysis. Because the technology analyzed reservoir fluids instead of local wellbore entrained gas, the accuracy was higher than data from other techniques.

MULTI-ZONE INVESTIGATIONS

Based on this survey's success, Black Diamond and WellDog are moving forward with investigations to characterize, select and produce a package of coal seams using multi-zone completion techniques. This DOE-sponsored work involves drilling 12 wells on four adjoining pads into three different seams in the Powder River basin's Landry field.

Each seam will be tested in each area for critical desorption pressure, initial gas saturation and gas content. Using that information, target coals will be selected for completion and production. The resultant production will be compared to a control case in which all seams are completed and produced.

Comparisons possible in this study include: top set versus perforated completion methods in single- and multi-zone scenarios and single- versus multi-zone production metrics and success. As a result of this study, Black Diamond will be able to directly assess the impact that careful reservoir characterization and selective completion methods can have on multi-zone production from coal seams.

Editor's note: WellDog, Inc. and Rocky Mountain Oilfield Testing Center were recently awarded the Outstanding Partnership award by the Federal Laboratory Consortium for their collaboration during development of WellDog's breakthrough coal bed methane dissolved gas evaluation technology. In 2005, that technology led directly to commercialization of WellDog's Critical Gas Content service.

THE AUTHORS

|

|

Eric Koval earned a BS in petroleum and natural gas engineering from Penn State University and is the founder and president of Black Diamond Energy, Inc. His experience includes reservoir, production, and management assignments throughout the US with Atlas Resources, Inc. and Marathon Oil Co.

|

|

|

John Pope earned a BS in physics from the University of Missouri-Rolla and a PhD in physical chemistry from the University of Wyoming. He is the founder and chief technology officer of WellDog, Inc. Pope sits on the Wyoming CBM Water Use Task Force and on the Interstate Oil & Gas Compact Commission's Energy Resources, Research & Technology Committee. Pope has founded eight companies in a range of business sectors. Email: JPope@welldog.com.

|

| |

|

|