New products

Vol. 227 No. 2 Compact, high-pressure meter Emerson Process Management has added high-pressure capability to the Micro Motion F-Series compact Coriolis meter

Compact, high-pressure meter Emerson Process Management has added high-pressure capability to the Micro Motion F-Series compact Coriolis meter line. Rated to 5,000 psi (345 bar), this new meter offers flow and density measurement in demanding, high-pressure environments at flowrates up to 300 lb/min (8,160 kg/h). This new solution expands the capability of the F-Series compact design, while expanding the power of Emerson’s PlantWeb digital plant architecture to improve manufacturing quality. The Micro Motion Coriolis sensor provides excellent measurement accuracy for mass flow, density and volume flow. When combined with Micro Motion MVD technology, the F-Series meters deliver mass flow accuracy up to ±0.1% and volume flow accuracy up to ±0.15% when measuring liquids. On liquid density, Micro Motion F-Series meters are accurate up to ±0.001 g/cc. The flowmeters have no moving parts to wear out or break down, and do not require periodic recalibration.

Maintenance-free single-gas detector  The ALTAIR Single-Gas Detector from MSA Instrument Division features three sensor options: carbon monoxide, hydrogen sulfide and oxygen. CO and H2S versions can operate for over two years. The design offers superior dust and water protection and high resistance to RFI. A rubberized housing and one-button operation provide durability and ease of use. The triple-alarm system features two bright LEDs, a piercing audible alarm and a vibrating alarm. The detector automatically records the last 25 alarm events. To read data or change alarm set points, user connects the unit to an MSA infrared adapter using the built-in IR communication port.

Geomodeling software Geomodeling Technology Corp. announced that multi-phase upscaling has been included in its feature set of SBED software. SBED is the only commercial software for modeling the small-scale geological heterogeneity that impacts large-scale reservoir performance. Multi-phase upscaling allows the fundamentals of physical composition on one level to be encapsulated on a larger level. Conventional reservoir modeling technologies extrapolate relative permeability curves measured from core plugs to full-field reservoir model, without considering the impact of small-scale geological details. Understanding all of the processes involved in fluid flow through sedimentary rocks is key to understanding contaminant migration and petroleum production. Other new features included in this release are: default saturation functions; project template to manage saturation functions; linear and periodic flow boundary conditions; multi-thread upscaling capability; and moving windows upscaling for irregular porosity/ permeability grids.

Handheld plasma cutter  Designed for hand-held and automated cutting in the heavy fabrication industries, the new Spectrum 1251 air plasma cutting and gouging system from Miller Electric Mfg. Co. has a 100-amp output, can sever 1.75-in. steel and has a rated cutting capacity of 1.25 in. Rated cutting capacity is the speed at which an operator achieves a smooth, steady cut at 10 in. per minute using a hand-held torch. It is Miller’s most powerful plasma unit. On thinner material, cutting speed increases. The Spectrum 1251 cuts 3/4-in. steel at 25 IPM, 5/8-in. steel at 40 IPM and 1/4-in. steel at almost 140 IPM. It also cuts stainless, aluminum, copper and any metal that conducts electricity.

HPHT viscometers  Model 7600 HPHT viscometer from Chandler Engineering is the world’s first viscometer designed to measure rheological properties of drilling fluids under Extreme High Pressure and High Temperature (XHPHT) conditions – temperatures up to 600°F (316°C) and pressures up to 40,000 psig (2,758 bar). The result of a joint development effort between Chandler Engineering and Baker Hughes Drilling Fluids, the new viscometer is one of a suite of highly specialized instruments designed to support oil and gas exploration.

Salt inhibitor for low-pressure gas wells Brenntag has developed the T-3000E salt inhibitor to prevent salt deposition in low-pressure gas wells. The new product, which consists of a concentrated blend of water-soluble and biodegradable compounds, offers an alternative to flushing warm water during production, saving production time. Salt precipitation can block the flow path of hydrocarbons, and is particularly severe in wells with high saline, forming brines, or brines near saturation with respect to sodium chloride. This phenomenon occurs more frequently in gas wells and is caused by low pressure and decreasing temperatures. T-3000E modifies the crystal orientation of salt from symmetric cubic to random dentric crystals, which means it takes longer to grow crystals and those random crystals do not block the flow path. This property delays salt deposition and prevents the formation of a hard plug. Instead, pumpable salt slurry is formed, which can easily be flushed from the wellbore. This treatment will prolong the time in between cleanouts and increase production.

Oil and gas mapping WhiteStar Corp. announced the addition of Louisiana, Wyoming and Utah to its CartoBase subscription line of digital cartographic products designed for oil and gas mapping. WhiteStar introduced CartoBase in 2005 with the introduction of Texas and Colorado statewide products. CartoBase products are offered on a subscription basis, whereby clients receive quarterly updates of key data layers for two to three years following the initial purchase. Each product contains up to 24 seamless layers of geospatial data covering the entire state and delivered on DVDs equipped with the CartoBase application that allows users to export data in their choice of mapping formats. Each CartoBase product contains high-resolution statewide data coverage from the company’s national database products, including: Public Land Survey Grid containing the 1:24,000 land base derived from US topographic maps; Pipeline Database of the location and attribute details for oil, gas and petroleum pipelines operating in the state; and Well Location File including the location and attribute information for oil, gas and coalbed methane well heads.

Integral packer system TAM International recently developed the Hatch Packer, a patent pending tool featuring unified construction that incorporates the TAM Port Collar (PC) and Casing Annulus Packer (CAP) into an integral assembly for non drill-out, minimum-trip, stage cementing. The Hatch Packer is available with premium connections and the proven SafeLok valve system in the CAP. The primary benefit of the integral system is 100% assurance of packer valve system closure, including optional metal-to-metal seals. Running in with the TAM Combination Tool (CT) allows actuation of the Hatch Packer’s PC sleeve, and selective inflation of the packer, if required. The PC sleeve is then opened and the well circulated and cemented. Closure of the PC blocks the CAP inflation ports to assure casing integrity. The PC is then tested and the combination tool retrieved.

|

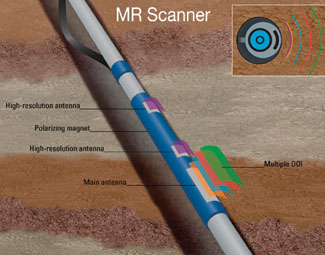

The MR Scanner expert magnetic resonance service is a nuclear magnetic resonance wireline logging tool. Making simultaneous multi-frequency measurements, the tool investigates the formation at multiple depths in a single pass. Its unique measurement sequence gives a clear profile of reservoir fluids, and its eccentered design keeps the measurement depths on track, regardless of the hole size or temperature. Multiple antennas enable simultaneous measurements. Information from four depths of investigation – 1.5 to 4 in. – gives a profile of saturation distribution and formation damage from a single pass. The Rt Scanner triaxial induction service calculates vertical and horizontal resistivities from direct measurements, while solving for formation dip at any well deviation and in anisotropic formations. Its measurements at multiple depths of investigation in all three dimensions ensure that the derived resistivities are a true 3D measurement.

The MR Scanner expert magnetic resonance service is a nuclear magnetic resonance wireline logging tool. Making simultaneous multi-frequency measurements, the tool investigates the formation at multiple depths in a single pass. Its unique measurement sequence gives a clear profile of reservoir fluids, and its eccentered design keeps the measurement depths on track, regardless of the hole size or temperature. Multiple antennas enable simultaneous measurements. Information from four depths of investigation – 1.5 to 4 in. – gives a profile of saturation distribution and formation damage from a single pass. The Rt Scanner triaxial induction service calculates vertical and horizontal resistivities from direct measurements, while solving for formation dip at any well deviation and in anisotropic formations. Its measurements at multiple depths of investigation in all three dimensions ensure that the derived resistivities are a true 3D measurement.