What's new in production

“Wasted” energy. Natural gas was once “waste” in many oil fields. As a by-product, it was flared without any thought of selling it. That practice has changed. Fear of climate change from increasing CO2 concentrations, government regulations and community pressure pushed power generation toward gas. Since about 40% of the CO2 produced comes from burning coal, and gas is soot-, mercury- and sulfur-free, electric companies shifted to gas turbine technology. Gas became the fuel of choice, and it sold for a solid profit. Suddenly, gas that sold for $2/Mcf in 1999 now sells for well over $6/Mcf. Once oil companies accepted that many people and governments consider gas flaring a factor in climate change and, more to the point, were willing to pay a premium for clean gas, oil companies began to examine ways to keep hydrocarbons from being consumed by field operations. Recently, a few began looking for alternative energy sources to preserve their high-value hydrocarbon production. Thus, alternative fuels entered the oilfield – photovoltaic, hydrogen and wind. If oil and gas could be preserved, then more hydrocarbons could be sold for a profit in the continuing high-price environment. Conservation and enhanced recovery improve the lifetime productivity and ultimate return from producing assets. It makes good business sense. Three alternate energy oilfield projects show how the industry is moving to preserve and extend value through different energy replacement strategies. Photovoltaic. Utilizing a subsidy offered by the State of California, Chevron has installed a six-acre, 500-kW photovoltaic array in Midway-Sunset field, 40 mi from Bakersfield in the San Joaquin Valley. According to Chevron, the SolarMine is the first photovoltaic system built to support an oil installation using flexible, amorphous-silicon panels to generate electricity. Formerly ignored, solar energy now offsets burning hydrocarbons to power Chevron’s field operations. The array produces power to drive pumpjacks and processing plants, and is connected to the local utility grid. The amorphous-silicon solar panels were chosen, because they can be struck or pierced without harming their electric generation capability, and apparently because Chevron owns a 20% stake in ECD, the photovoltaic manufacturer. Chevron Energy Solutions (CES), the subsidiary that installed the array in June 2003, is monitoring its performance. CES expects wider application of the technology to other commercial and industrial sites. There may be a photovoltaic array in your oil field’s future.

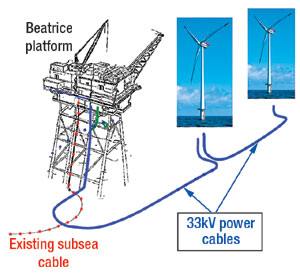

Hydrogen. BP, ConocoPhillips and Shell, along with Scottish and Southern Energy (S&SE) are preparing to build a decarbonized power system that will produce oil through an enhanced recovery/CO2 sequestration project. The plan involves building a reformer plant onshore near Peterhead in northeast Scotland to strip hydrogen from natural gas. The hydrogen will be burned to produce electric power in a 350-MW plant, while the reformer’s waste CO2 (1.3 million tonnes/yr) will be shipped through pipelines to Miller field, 240 km northeast of Peterhead in the North Sea. Miller field was scheduled to cease production in 2006 – 2007, but the reformer’s CO2 will lift the ultimate oil production by up to 40 million barrels and extend the field’s life by 15 – 20 years. Project engineering will be completed in third-quarter 2006 to bring the project online in 2009. Wind. The Beatrice Wind Demonstrator Project in the North Sea is a joint venture between Talisman Energy and Scottish and Southern Energy (S&SE), which seeks to test windpower and preserve the Beatrice field offshore platform. Beatrice field production declined to 4,270 bopd in 2004 from 7,406 bopd in 2002, placing the structure in line for future decommissioning. The platform will now become a power gathering station for a small offshore wind farm while it produces the remaining oil. Contracts were let in December for the construction of two 85-m substructure jackets and foundation piles, which will support two wind turbines in a 45-m water depth. Last month, a contract was let for two composite power cables with 33-kV cores. Electricity generated will be used for oil production. The five-year project has been incorporated into Europe’s DOWNVInD (Distant Offshore Wind Farms with No Visual Impact in Deepwater) initiative. Talisman and S&SE will collect performance data, reduce costs and develop operating procedures for future, larger, offshore wind farms. Installation is scheduled for summer 2006, with the first power to go online in fourth-quarter 2006. Missed fuel. The one alternative “fuel” that seems to be untested by the industry is solar thermal collection. This power source is already being used for electrical generation at nine installations in California’s Mojave Desert. Parabolic trough mirrors focus sunlight on tubes carrying oil as a working fluid; the oil transfers solar energy to water in several stages, producing steam. The steam then spins turbines to generate electricity. For more, visit www.solel.com. This conventional application could be easily transferred to heavy oil properties that need steam to heat/ melt low-gravity crudes, rather than burn produced crudes and natural gas, or purchase electric power from fossil fuel plants to generate steam. As much as some folks in the oil industry decry alternative power for general use, there is a business case to be made for its oilfield application. In fact, there is likely a cost-effective, alternative energy source to power many oilfield operations – the original source. Let the sun provide the energy and sell more crude!

|

|||||||||||

- What's new in production (February 2024)

- Prices and governmental policies combine to stymie Canadian upstream growth (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- U.S. producing gas wells increase despite low prices (February 2024)

- U.S. drilling: More of the same expected (February 2024)

- U.S. oil and natural gas production hits record highs (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)