| Vol. 227 No. 12 |

|

Rig floor equipment

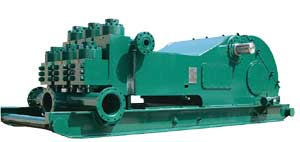

Two mud pumps offer permanence or lighter weight

Ellis Williams Engineering Co., Inc., based in Magnolia, Texas, has developed and manufactured a pair of 2,200 hp mud pumps for offshore and land rig applications. The E-2200 and EH-2200 pumps represent an evolution in pump design and are constructed to achieve maximum horsepower, while allowing for continuous duty in all drilling operations. The two different designs provide the customer with heavy and continuous-duty pumps.

The E-2200 is a full-size, standard-weight pump with a 15-in. stroke and a piston-rod, load rating of 158,374 lb. This pump has an average bearing life of 125,000 hr and is rated at 110 strokes per minute.

The counterpart design, the EH-2200, gives the customer a lighter weight, smaller footprint and a more portable pump than the full-sized pump. This pump has a 14-in. stroke and is rated at 125 strokes per minute. The bearing life averages 100,000 hr and the piston-rod load is rated at 149,324 lb.

|

The E-2200 and EH-2200 pumps represent an evolution in pump design and are constructed for maximum horsepower and continuous duty.

|

|

Unlike other pumps in the industry, both the E-2200 and EH-2200 have balanced crankshafts. Each crankshaft is balanced by design and is produced through expert craftsmanship and precision machining to last the pump’s life.

While the E-2200 has a lower stroke rate than the EH-2200, the E-2200 has a longer life expectancy for all expendable parts. The E-2200 is specifically designed for permanent installation on offshore rigs.

While the EH-2200 provides the same continuous-duty, long-life operations as the E-2200, it is one-third of the weight and nine inches shorter than the full-size model. This is because of the EH-2200’s smaller gear diameter and reduced cross section.

Because of decreased bearing selections for the EH-2200 model, the pump’s drive train components are one category size smaller. This is seen in the crosshead assembly that determines the pump’s width. The EH-2200 can use bearings with 17-18% less capacity rating, due to the 6%-less load and 6%-less life factor of its bearings.

To achieve a minimum weight fluid-end, the company offers a valve-over-valve arrangement rated at 5,000 psi, as an option on the EH-2200. To reach 7,500 psi on this pump, a customer can choose between a “SW style” fluid end and a Mattco Quantum. These options provide a 7,500-psi rating with a minor weight penalty.

The EH-2200 pump can be run at higher speeds than the E-2200, but this action will cause a 9% increase in usage rate for its fluid-end, expendable parts. The EH-2200 can be used on both offshore and land rigs.

|