New products

Seismic software suite Paradigm announced the release of Rock & Fluid Canvas 2007, an integrated software suite of 10 applications for seismic processing and imaging, seismic interpretation, subsurface modeling and reservoir characterization. The software creates a shared “canvas” for all the applications to merge the macro realm of geology and geophysics seamlessly with the micro realm of petrophysics. Among key features of the applications, they allow customers to deliver a common visualization, interpretation and transformation platform; vet, analyze and interpret prospects; see a significant increase in productivity with automation tools; execute simultaneous multi-disciplinary tasks; audit workflows for reserve reporting with Workflow Guides; push/ pull data from OpenWorks and GeoFrame; and share data with third-party applications.

Pipeline security system

Drilling/ completion software suite Petris has released PetrisWINDS DrillNET, a drilling and completion engineering software framework that combines the capabilities of its Maurer drilling programs into one integrated package that permits data to be captured, reused and shared among users. Based on the Microsoft .NET architecture, DrillNET has an intuitive user interface and integrated database coupled with context-sensitive help and a “traffic light” approach to check that all data is complete for a calculation. Output reports can be generated from the results, and the data are exported to Microsoft Office products. Additionally, the software is available in multiple languages, including English, Russian, Spanish and Chinese, and can be configured for each user to allow the use of one language for the program operation and another one for report generation.

Microhydraulic jets

Wireless networks Wireless multi-service mesh technology from Firetide provides highly secure wireless network extensions on the rigs, where conventional network cabling is difficult or impossible to install. The technology eliminates the need for outdoor cabling altogether and extends networks by simply installing wireless mesh nodes instead. Unlike other systems that require Wi-Fi for access, the Firetide solution provides standard Ethernet connectivity over the wireless mesh, so any network device can operate wirelessly without reconfiguration. Because multi-service mesh networks allow any network device or application to operate over the wireless infrastructure, system integrators can deploy concurrent video, voice and data to any location. The mesh is self-forming and self-healing to ease setup and installation, while management tools enable network tuning, monitoring and network control.

Pump industry website The Hydraulic Institute announced the re-launch of the pump industry’s website, www.Pumps.org. Users may access an array of free downloads, reference materials, pump definitions, pump diagrams, and information on upcoming events and news. An online Supplier Finder allows users to search for manufacturers by a variety of criteria, including product description, brand name or market. Additionally, visitors can now access the Institute’s extensive library of PumpFAQs – a series of question-and-answer articles on a wide variety of topics published as a service to pump users, contractors, distributors, reps and OEMs.

Oil & gas accounting software Merrick Systems has released ProCount 2007. This latest version of its comprehensive hydrocarbon accounting solution addresses the complex allocation requirements for oil and gas companies operating onshore and offshore. Enhancements from earlier versions of the product include: broad, international usability – mixed unit support stores data in one basic unit, and offers the ability to display it in whatever unit the user requires; custom configurability – robust reporting and innovative interfaces allow users to build screens and add fields as needed; and full global service capabilities. The software is highly configurable. The drawing module allows users to gather complete systems for allocations, add new properties and confirm configurations with field personnel. Schematics let users add multiple components, such as wells, meters, tanks and equipment, to a drawing at one time, establishing significant date connections. ProCount 2007 also features daily and monthly volume reconciling, and it makes information available to all users as it is entered. New security features include password encryption, and users can be blocked from portions of the database, regardless of the query tools used.

Subsea simulation General Robotics Ltd has introduced DeepSim 1.0, its desktop subsea planning and training simulator. DeepSim runs under Windows XP, and provides real-time dynamic visualization of complex subsea scenarios, allowing users to model the true hydrodynamic response of objects such as ROVs, tethers and moorings when acted on by real-world factors like currents and surface vessel motion. The software is primarily for contractors in the offshore oil and gas industry, typically involved in survey, inspection, maintenance and repair of subsea installations, as well as drilling and laying of pipelines. By allowing the play and replay of any subsea situation, DeepSim provides a tool for training and planning, and generating marketing proof-of-concept visualizations. GRL provides a free Replay Viewer, which can be downloaded from the company’s website or distributed by DeepSim users with their simulations. Simulations are modelled in full 3D, so regardless of the original camera viewpoint, the user can replay the scenario from any angle or viewpoint. Camera tracks can be created to define the routes that the camera will take, each of which is, in effect, a separate “movie”, so different tracks can be created for training vessel or ROV pilots, or for marketing. Another feature is the general hydrodynamic modelling of dynamic cable behavior in water. The operator can add any number of wires, cables, and chains, and they will be modelled on their physical properties – mass, density and drag – to take into account currents or vessel speed, and these objects will behave in a hydrodynamically accurate manner. The software comes with a database of objects, vessels, structures, seabeds and custom components that can be pulled into the simulation by the user. Users can extend the database with models of their own.

M-I SWACO has prepared a 4-color brochure describing its new FloThru reservoir drill-in fluid (RDF), which delivers an oil-permeable filter cake requiring lower flow-initiation pressures, thereby permitting oil to readily pass through while reducing water production. The system employs a proprietary hydrophobic-carbonate component in combination with a hydrophobic starch that essentially creates oil-preferential channels through the filter cake, increasing production while lowering completion cost.

|

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)

Watson-Marlow Bredel has introduced the PetroProof pump, the first industrial high-pressure hose pump able to pump petrochemicals such as hydrocarbons and oils. The pump utilizes a new, proprietary, oil-resistant hose material that serves as an alternative to rubber, which has a short lifetime. Hoses are available for a range of Watson-Marlow Bredel pump types, including: SP/10, SP/15, SP/20 and SP/25. With these pumps, the product does not come into contact with any metal or moving pump parts, making them suitable for handling abrasive as well as corrosive products. Finite element modelling was used to design the various hose sizes, ensuring maximum performance under a range of service loads. The hoses are optimized for compression force, internal pressure and expected lifetime.

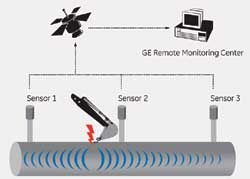

Watson-Marlow Bredel has introduced the PetroProof pump, the first industrial high-pressure hose pump able to pump petrochemicals such as hydrocarbons and oils. The pump utilizes a new, proprietary, oil-resistant hose material that serves as an alternative to rubber, which has a short lifetime. Hoses are available for a range of Watson-Marlow Bredel pump types, including: SP/10, SP/15, SP/20 and SP/25. With these pumps, the product does not come into contact with any metal or moving pump parts, making them suitable for handling abrasive as well as corrosive products. Finite element modelling was used to design the various hose sizes, ensuring maximum performance under a range of service loads. The hoses are optimized for compression force, internal pressure and expected lifetime. GE Oil & Gas’ PII Pipeline Solutions group has launched its new ThreatScan technology, which is deployed to monitor pipelines threatened by third-party damage, the world’s leading cause of pipeline failures. While some damage causes immediate failures, in other instances damage can go unnoticed, only to develop into leaks or failures years later. The ThreatScan system is designed to reliably monitor the entire pipeline length 24 hours-a-day, ensuring fewer false calls and rapid notification of the location of any impact. In addition to immediately notifying operators of specific impacts in a given pipeline, the system offers monthly summaries of dates, times and locations of all impacts. ThreatScan is extremely sensitive and can filter out incidental noise while still detecting the most minor pipeline strikes. Using ATEX-certified sensors, an on-site processor, satellite communications equipment and, when appropriate, a solar-based autonomous power supply, the system is easily installed on existing above-ground pipeline structures and fittings, allowing pipelines to be retrofitted without excavation.

GE Oil & Gas’ PII Pipeline Solutions group has launched its new ThreatScan technology, which is deployed to monitor pipelines threatened by third-party damage, the world’s leading cause of pipeline failures. While some damage causes immediate failures, in other instances damage can go unnoticed, only to develop into leaks or failures years later. The ThreatScan system is designed to reliably monitor the entire pipeline length 24 hours-a-day, ensuring fewer false calls and rapid notification of the location of any impact. In addition to immediately notifying operators of specific impacts in a given pipeline, the system offers monthly summaries of dates, times and locations of all impacts. ThreatScan is extremely sensitive and can filter out incidental noise while still detecting the most minor pipeline strikes. Using ATEX-certified sensors, an on-site processor, satellite communications equipment and, when appropriate, a solar-based autonomous power supply, the system is easily installed on existing above-ground pipeline structures and fittings, allowing pipelines to be retrofitted without excavation. The Lee Company’s new 156 Jet is a 0.156-in.-diameter, single-orifice restrictor based on the same technology as the 0.187-in.-diameter Lee Jet. Nominally weighing only 0.7 grams, the 156 Lee Jet offers a 42% weight savings over the 187 Lee Jet and is 12.5% shorter, resulting in a corresponding reduction in installation boss size and weight. Available in 34 standard Lohm rates (3,000 to 30,000 Lohms), the jets are 100% bi-directionally flow-tested to ensure accurate performance.

The Lee Company’s new 156 Jet is a 0.156-in.-diameter, single-orifice restrictor based on the same technology as the 0.187-in.-diameter Lee Jet. Nominally weighing only 0.7 grams, the 156 Lee Jet offers a 42% weight savings over the 187 Lee Jet and is 12.5% shorter, resulting in a corresponding reduction in installation boss size and weight. Available in 34 standard Lohm rates (3,000 to 30,000 Lohms), the jets are 100% bi-directionally flow-tested to ensure accurate performance. Reservoir drill-in fluid

Reservoir drill-in fluid