Drilling Technology

Barnett Shale operators extend geo-steering to "geo-navigation"

Karsted limestone creates drilling challenges

Kelly Myers, Consultant; Paul Sandwell and Dee Jenkins, Energy Frontiers Services

For years, operators have used various software applications to interpret survey data and logging attributes in horizontal wells, collectively creating "geo-steering." The most common practices involve using MWD gamma-ray data and other attributes to help drill horizontal wells. Some operators in the Barnett Shale trend are using this technology for frac design and planning. The more important uses are:

- Conventional geo-steering

- Detecting faults and other vertical discontinuities

- Avoiding certain zones and risk management of borehole placement

- Hydraulic fracture stimulation design and planning.

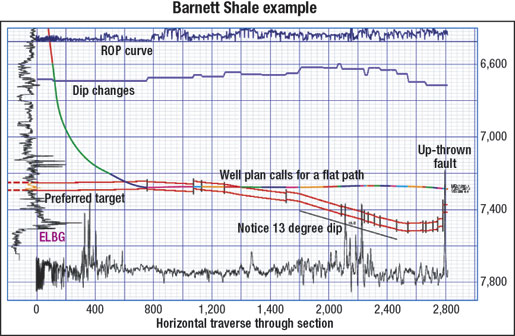

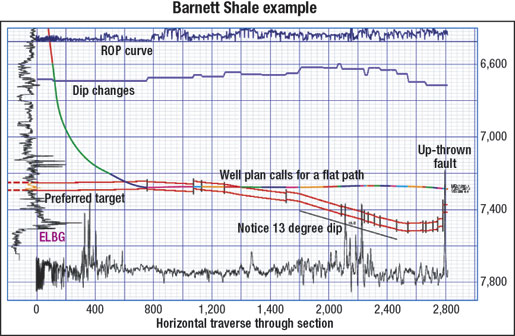

A common myth in the Barnett play is that the Fort Worth basin is tectonically simple. This view is reinforced by the lack of good well and seismic control. Even where there are seismic data, the resolution is often too poor to show faults with less than 30 ft of throw. The advantage of geo-steering software is that a coherent structural picture can be developed along the horizontal well path, revealing subtle faults, collapse features and zones with higher fracture occurrence and matrix porosity.

Geologists and engineers have used conventional geo-steering to guide them and to discern the stratigraphy intersected. Operators can adjust the trajectory of the planned well path in response to geologic conditions, correcting the bit as needed. One of the biggest concerns is making certain that a well path does not stray too close to the underlying Ellenburger Group which is often water-bearing.

Geo-steering is important in fault detection. Operators report that it is best to avoid the perforation of fault zones over 10 ft wide. The interpretation becomes a map to place wells around the faulted zones, so frac energy is not lost to small faults.

|

Fig. 1. The well path in the Barnett Shale should not stray too close to the underlying Ellenburger limestone, which has sinkholes and is often water-bearing.

|

|

Some larger faults conduct water from overlying and underlying carbonates. It is tempting to perforate the faulted areas, as they often have open fractures, giving good quality gas shows.

A common feature is the sinkhole, caused by karsting. This produces structural dips in the Barnett exceeding 30°. Sinkholes also have more faulting localized around their rims and dimensions of the sinkhole can fall within the length of a typical horizontal well. Trying to stay within a narrow target interval in such a situation is usually not practical. But, knowing the relative stratigraphic and structural picture is important for completion and stimulation decisions.

Analysis of the Barnett Shale is in its infancy. The hope is to eventually know how big a role structure plays, if zonation is present, and how large an impact faulting has on overall production.

Geo-steering and interpretation are tools to help operators get to their target as cheaply and quickly as possible, stay close to the target, collect data for fracing, and create a better knowledge base.

In the past, geo-steering software was used mostly for drill bit targeting and for calculating dip angles. Modern geo-steering applications are capable of detecting faults and other vertical discontinuities with a high degree of certainty. Engineers can measure fault displacements with sub-foot accuracy. They can detect other vertical discontinuities, such as the boundary of a collapsed-breccia zone or the edges of a homogenous reef. These abilities transcend geo-steering to become "geo-navigation."

|

THE AUTHORS

|

|

Kelly Myers is a professional consultant to the industry. Myers earned a BS degree in geology from the University of Texas, Austin, in 1982.

|

|

|

Paul Sandwell is a partner with Energy Frontiers Services. He earned his BS degree in physics from Birmingham University.

|

|

|

Dee Jenkins is a partner in Energy Frontiers Services and Energy Frontiers Partners. Jenkins earned an MS degree in geology from Texas Christian University.

|

|

|