Well Logging/ Formation Evaluation

Advances in MWD and formation evaluation for 2005

Developments include DVD and Web-based information sources, wireline and while-drilling logging methods, fast formation pressure measurements, and coring and scanning technology.

David Patrick Murphy, Shell Exploration & Production Co., Houston

The latest advances in formation evaluation, especially data acquisition while drilling, are improving quality and increasing the quantity of formation data while reducing costs and making operations more efficient. Some of those advances discussed here include:

General – DVD information sources, online rock catalog and well log printing

Wireline logging – Slim cased-hole resistivity and spectral pulsed neutron applications

MWD/LWD – NMR, acoustic, seismic while drilling and imaging logs

Testing – Fast wireline pressure tests

Coring and Analyses – Sidetrack coring and portable coiled tubing computed tomography (CT) scanning.

GENERAL

Reference disks provide formation evaluation and MWD information. Rock catalogs provide analog rock data. Well log printers can be used for printing logs or making copies.

SPWLA transactions and journals. The Society of Petrophysicists and Well Log Analysts (SPWLA) has completed its published Transactions of the SPWLA by adding a DVD containing Volumes 36-41 (1995-2000) in high-resolution Adobe Acrobat PDF image file format, Fig. 1.1 This transactions DVD is priced at US$40 for a single-user license. SPWLA has also published a DVD containing its journals (The Log Analyst and Petrophysics) from 1960-2002. The journals DVD is priced at US$90 for a single-use license. Those interested in network or corporate licensing may contact SPWLA directly at www.spwla.org.

|

Fig. 1. SPWLA Transactions (1995 – 2000) and journals The Log Analyst and Petrophysics (1960 – 2002) are available on DVD.1

|

|

Rock catalog. USGS Open-File Report 03-420 provides a downloadable rock property catalog of porosity and permeability from core plugs in siliciclastics.2 Information is provided for 70 data sets taken from published data and descriptions. Data sets generally represent specific formations, usually from a limited number of wells. Each data set contains a written summary, permeability vs. porosity plot, and a spreadsheet file of the data. Included in the summaries are the publication reference, formation geologic age, location, well names, depth range, various geologic descriptions and core measurement conditions (if known).

Attributes such as grain size, auxiliary mineral content, or depositional environment are identified by symbols on the porosity vs. permeability plots. The data set is restricted to measurements on core plugs in conglomerates, sandstones, siltstones and shales. It can be accessed free of charge from USGS at http://pubs.usgs.gov/of/2003/ofr-03-420/.

Log printer. Neuralog has introduced NeuraLaser, a high-speed black-and-white well log printer.3 It can use different paper widths, allowing for the printing of full-scale or half-scale well logs. NeuraLaser can be connected to an individual PC via USB or can be a network-shared printer via its built-in Ethernet interface. An optional active stacker on the cart allows the printer to control log paper folding. NeuraView, Neuralog’s software for viewing and printing logs from TIFF images and LAS files, is included with the NeuraLaser. Track and curve layout/ coding of LAS data can be handled by NeuraView or customized by the user. NeuraView can be used on a stand-alone PC or across a network. It also supports color for use with other printers. When coupled with the developer’s NeuraScanner well log scanner, NeuraLaser can be used to copy well log prints.

|

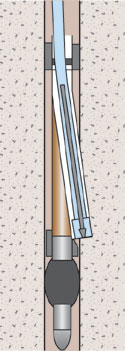

Fig. 2. Schlumberger’s CHRF-Slim cased-hole formation resistivity tool is designed to be run within casing below tubing without need to pull the tubing out of the well.4

|

|

WIRELINE LOGS

Two cased-hole wireline logging tool types are discussed.

Cased-hole resistivity. Cased-hole resistivity applications include cost savings via openhole log replacement, obtaining data if openhole logging was not possible, and reservoir saturation monitoring. Schlumberger’s new slimhole cased-hole resistivity log, CHFR-Slim, Fig. 2, is only 2-1/8-in. OD and can be run in casing as small as 4-1/2-in.4 It can be run below tubing without pulling the tubing, provided the tubing has a minimum 2-1/4-in. ID. CHFR-Slim tool can be conveyed via a tractor or coiled tubing and is combinable with the company’s PS Platform production log and Reservoir Saturation Tool RST-Pro nuclear saturation monitoring log.

Pulsed neutron. Two nonconventional uses of pulsed neutron capture (PNC) and spectral pulsed neutron logs (PNS) are discussed.

Open-hole density logs count backscattered gamma rays from a radioactive gamma ray source to obtain formation density information. Gamma rays created by cased-hole PNC logs provide formation density information but are complicated by capture gamma-ray contribution during the neutron burst. Halliburton’s PNC modeling work has provided it with a correction technique that isolates a significant amount of the formation density information.5

This correction technique uses measurements that have been on PNC logs for some time, allowing evaluation of this technique on previously run field logs. While good correlation between cased-hole and openhole density logs can be observed, at the present time, cased-hole formation density measurements are somewhat inferior to open-hole formation density measurements because of the cased-hole environment’s complexities and uncertainties.

Halliburton has recently published examples of using PNS to derive open-hole-quality potassium (K), uranium (U), and thorium (Th) spectral gamma ray information in cased holes.6 The KUTh measurements must be made before the PNS neutron generator has been activated in the well, otherwise neutron activation of the iron (2.3-hr half-life) in the casing and tool housing will cause inaccurate KUTh values.

MWD/ LWD

MWD/ LWD formation evaluation tool suites are providing additional measurements and higher resolution versions of existing measurements.

NMR. MagTrak is a 6-3/4-in. while-drilling NMR from Baker Hughes INTEQ.7 It can be run in 8-3/8- and 8-1/2-in. boreholes. For ease of operation, MagTrak has been pre-programmed with operating sequences to make measurements over a wide range of formation and fluid properties. For each selected mode, raw data is processed downhole, and computed parameters such as porosity and clay-bound water are transmitted to surface in real time. User-defined measurement parameters can also be programmed for special applications. All raw data is stored in downhole memory for more advanced post-job processing after the tool is brought to surface. The MagTrak sensor sub uses an independent alternator and, therefore, requires mud flow for operation.

Acoustic. Schlumberger’s sonicVISION sonic-while-drilling tool acquires acoustic velocity measurements from 6-3/4-, 8-1/4-, and 9- in. collars.8 It has been run successfully in borehole sizes up to 30 in. Both compressional and shear velocities can be obtained in fast formations. Waveforms are captured in memory for more advanced post-processing. Additional quality control is performed using automatic station measurements made during connections. In this noise-free environment, the tool is able to make a station measurement that is sent to the surface when pumping resumes for further quality control of the real-time log. The sonicVISION tool is combinable with all other Schlumberger LWD systems.

Seismic while drilling. Halliburton and SensorWise have published design considerations and field test results of a seismic-while-drilling (SWD) system.9 Borehole seismic measurements while drilling allow correlation of drilled depth with seismic depth. Accurate borehole seismic measurements require accurate time synchronization between surface equipment and downhole sensors. Direct means of time synchronization are not currently available while drilling.

Halliburton tested a system using a stress-compensated-cut quartz crystal clock with a turnover point higher than expected maximum downhole temperature. The aging curve of the crystal is fully characterized through long-term testing and is corrected during use. Vibration effects can also be characterized through long-term testing and are corrected after vibrations are measured with a simple accelerometer system.

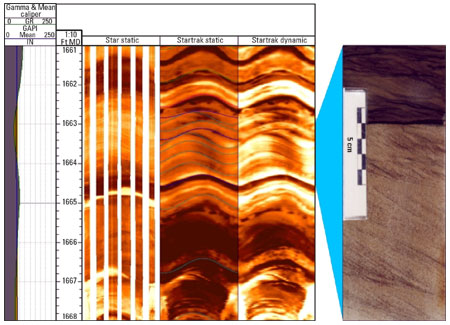

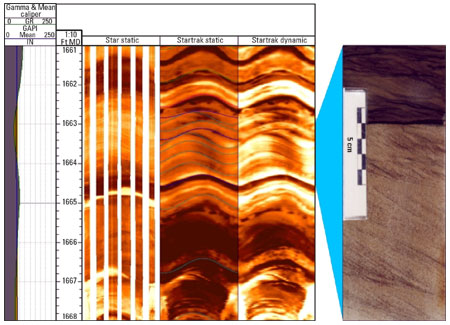

Electrical imaging. Baker Hughes INTEQ has developed and field tested StarTrak, a high-resolution, while-drilling galvanic-focused electrical imaging log, Fig. 3.10 StarTrak provides a full-circumference image and operates in conductive drilling fluids (water-based mud). Test well results in fresher muds (Rm 0.6 to 2.5 ohm-m) have indicated that a high-resolution image can be obtained comparable to that of wireline images, but without the image gaps normally associated with wireline imaging pad tools. Tests in a more extreme salt mud environment (Rm about 0.04 ohm-m and Rt about 200 ohm-m) showed favorable results.

|

Fig. 3. Baker Hughes INTEQ’s StarTrak full-circumference electrical image log (shown here with both static and dynamic image contrasts) can produce images comparable to that from a wireline electrical imaging tool (left image), but without image gaps associated with wireline pad tools.10

|

|

Nuclear imaging. Baker Hughes INTEQ has introduced azimuthal gamma ray and density imaging while drilling.11 The tool records eight azimuthal sectors for post-job imaging for structural and geological information and offers a choice of two or four sectors for using the images in real-time well navigation.

TESTING

Wireline formation test tools are using less rig time to obtain formation pressure information.

Wireline testing. Schlumberger’s PressureXpress is a combinable wireline pressure-only test tool designed for fast acquisition of formation pressure data.12 With this tool, the typical pressure measurement cycle (from setting the tool until it is retracted) is expected to last less than a minute. Because wireline pressure measurement sensors are subjected to sudden pressure and temperature changes, PressureXpress is equipped with a dynamic temperature compensation algorithm and packaging for rapid stabilization.

The tool’s OD and exterior profile are designed to reduce tool sticking risk. The short probe section has an eccentered 3-7/8-in. diameter, and the remainder of the tool body has a diameter of only 3-3/8 in. PressureXpress can be combined logging tool strings such as Schlumberger’s Platform Express.

|

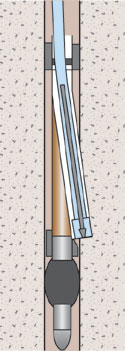

Fig. 4. Halliburton Security DBS sidetrack coring assembly is stabilized in the well using an inflatable packer.13

|

|

CORING AND ANALYSES

Coring and analyses provide rock for direct measurement of rock properties. Sidetrack coring and a portable CT scanner are discussed.

Sidetrack coring. Halliburton Security DBS has developed a new sidetrack coring (STC) assembly.13 With STC, the coring point can be selected after the coring objective has been penetrated, even after TD has been reached. The STC assembly is placed in the well just above the interval of interest so that core to be cut across the interval of interest is in a sidetrack beside the original borehole.

STC assembly is stabilized in place with an inflatable packer and contains a whipstock, Fig. 4. A standard 4-1/8-in. slimhole wireline core barrel/ bit, attached in the top of the STC assembly as it is run in the hole, is freed from the assembly using a shear pin once the STC is in place. The core barrel then slides down the whipstock as coring progresses, acquiring core from the sidetrack.

Portable X-ray core scanner. Lawrence Berkley National Laboratory has developed a compact and portable X-ray core scanner, Fig. 5.14 The Berkley Lab CT images are capable of multi-energy scanning to identify various materials comprising a core sample. 3D scans can be taken at a rate of 3 min./ft of core length. With whole-round core samples, resolutions between 50 to 200 microns can be achieved.

|

Fig. 5. Lawrence Berkley National Laboratory has developed a compact and portable X-ray core scanner for use at a well site or other remote location.14

|

|

Dimensions of the Berkley Lab scanner are 4.5 ft × 2 ft × 6.7 ft and the entire system weighs less than 660 lb, mainly due to the highly efficient design of the X-ray shielding. Its small size and light weight allow it to be taken to drilling sites or other remote locations. This equipment was used as part of the core analyses for the International Ocean Drilling Program.

ACKNOWLEDGMENT

The author would like to thank Shell Exploration & Production Company for permission to publish this article. The author gratefully appreciates technical details and insight provided by organizations and companies whose technology is discussed in this article.

LITERATURE CITED

1 Society of Professional Well Log Analysts, www.spwla.org, January 2005.

2 Nelson, P. and J. Kibler, A catalog of porosity and permeability from core plugs in siliciclastic rocks, USGS Open-File Report 03-240, 2003.

3 Neuralog, NeuraLaser Well Log Printer, http://64.33.127.26/products/neuralaser/, November 2004.

4 Herold, B., et al., “Combinable through-tubing cased hole formation resistivity tool,” Paper SPE 90018, SPE Annual Technical Conference and Exhibition, Transactions, September 2004.

5 Jacobson, L., et al., “An improved formation density measurement using PNC tools,” Paper SPE 90708, SPE Annual Technical Conference and Exhibition, Transactions, September 2004.

6 Reed, S., et al., “Cased-hole KUTh logging using a PNS tool,” Paper SPE 90709, SPE Annual Technical Conference and Exhibition, Transactions, September 2004.

7 Baker Hughes INTEQ, Technical data sheet 6-3/4-in. MagTrak, Brochure MTK-20-60-675-00, 2004.

8 Schlumberger, sonicVISION, Brochure 04-DR-075, www.slb.com/oilfield, May 2004.

9 Althoff, G., et al., “New concepts for seismic surveys while drilling,” Paper SPE 90751, SPE Annual Technical Conference and Exhibition, Transactions, September 2004.

10 Ritter, R., et al., “High resolution visualization of near wellbore geology using while-drilling electrical images,” Paper PP, SPWLA Annual Logging Symposium, Transactions, June 2004.

11 Jonsbråten, F., North Sea case study of azimuthal gamma ray and azimuthal density measurements, http://www.spe.no/bergen/doc/ one_day_seminar_04/pdf_disc/smaatroll/%20North%20sea %20case%20study%20of%20azimuthal%20gamma% 20ray.pdf, April 2004.

12 Schlumberger, PressureXpress, Brochure 04-FE-143, www.slb.com/oilfield, September 2004.

13 Halliburton Security DBS, Sidetrack coring, www.spe.no/bergen/ doc/one_day_seminar_04/pdf_disc/troldtog/2%20Side% 20track%20Coring.pdf, April 2004.

14 Freifeld, B., et al., Lightweight, portable X-ray core scanner, http://www.lbl.gov/Tech-Transfer/techs/lbnl1842.html, May 2004.

THE AUTHOR

|

|

David Patrick Murphy is regional learning leader for geoscience and petroleum engineering at Shell Exploration & Production Company. He is also formation evaluation lecturer for the University of Houston Graduate Program in Petroleum Engineering. Mr. Murphy is a licensed professional engineer in Texas, Oklahoma, Louisiana and California.

|

| |

|

|