New downhole technologies helped develop horizontal thin sand

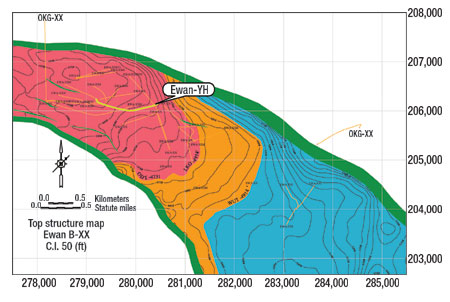

Drilling and Completion TechnologyNew downhole technologies helped develop horizontal thin sandCompletion of Well Ewan-YH with a 1,200-ft horizontal borehole in a 6-ft sand in Niger Delta, Nigeria, proved success of new downhole drilling technologies and reservoir management techniques.New drilling and formation evaluation technologies and reservoir management techniques enabled a horizontal well to be placed successfully within a thin hydrocarbon sand having structural dip and stratigraphic uncertainty, making it feasible to develop and produce reserves that have been unattainable both technically and economically. The Ewan-YH, Ewan field, Niger Delta, Nigeria, achieved its objective with a 1,200-ft horizontal well drilled through the thin, productive BXX sand using enhanced drilling technology, geosteering techniques and reservoir management. The well’s initial production was 1,600 bopd, exceeding expectations by 33%. Integration of logging while drilling (LWD) resistivity and resistivity images and nuclear magnetic resonance (NMR) measurements as well as a new rotary steerable system (RSS) enabled the well to successfully land and be geosteered in a 6-ft stratigraphic thick sand, and be geostopped at optimum drainhole length that met productivity targets. Incorporating these technologies in the bottomhole assembly (BHA) and transmitting and obtaining the information in real time has had a significant impact on drilling and completion decisions, regarding well placement, that impact productivity and overall well economics in Niger Delta. Specifically, the Ewan-YH horizontal well, its planning, execution and results will be discussed herein. SETTING OBJECTIVES, ASSESSING GEOLOGIC RISKS The process of drilling horizontal wells in Chevron Nigeria Ltd. (CNL) is generally executed in three main phases: planning, execution and post-job. Upfront planning by a multifunctional team for well placement determination, uncertainty management/ technology, and tool selection are key. Execution of landing and lateral placement, and length requires maximum flexibility and accuracy from tools and the team. The post-job reporting phase typically comprises an after action review – critical to learning from both mistakes and successes, and bringing each well experience to subsequent wells. The objective of the Ewan-YH was to place a horizontal well within a 6-ft thin sand and drill an optimal lateral length that would meet hydrocarbon deliverability requirements. Specifically, the plan called for targeting and landing within the 6-ft BXX sand and, after setting casing, drilling a 1,200-ft long horizontal lateral with 90E – 2E inclination within the sand. While offset wells provided both structural and stratigraphic control around the field, some structural uncertainties regarding target depth were present in the seismic mapping, Fig. 1. Key to reducing structural risk was use of near-bit LWD azimuthal resistivity. The well also presented stratigraphic risk as a result of shaliness within the reservoir; and the target sand decreased in both reservoir thickness and sand quality toward the west and SSW direction. Therefore, LWD NMR was added to evaluate the permeability both in the pilot hole and the drainhole section.

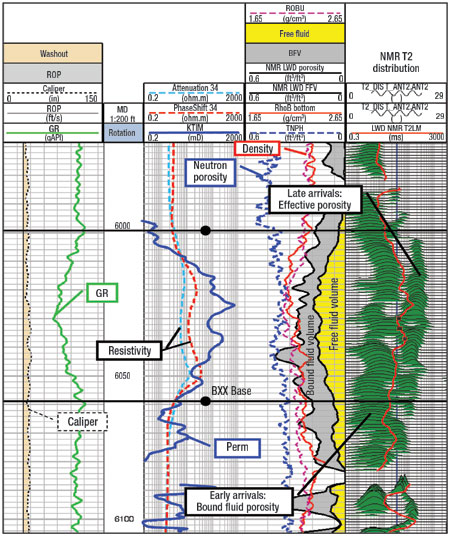

To help reduce the possibility of exiting the sand, the drain was planned along its strike, which reduced structural uncertainty and helped achieve generally flat dip. While better reservoir quality was expected near the fault, lack of nearby well control coupled with high structural dip limited the ability to target the drain hole along strike of the NW trending fault. The team optimally placed Ewan-YH between two wells, where one supported placement of the toe while the other defined a zone of likely poor productivity. UTILIZING NOVEL FORMATION EVALUATION TECHNOLOGIES To drill the Ewan-YH, the BHA for the 6-in. drainhole section was optimized to reduce geological risks. It was recommended to use the Schlumberger geoVISION* downhole MWD/ LWD imaging services for at-the-bit resistivity, near-bit azimuthal button resistivity and azimuthal resistivity images to geosteer the well within the thin sand. The geoVISION* NMR tool was also used to obtain NMR measurements for calculating effective porosity and permeability, and analyzing drainhole productivity while drilling. This allowed geostopping the drainhole length at the optimum total depth (TD) to achieve productivity targets. The azimuthal resistivity tool provides a laterolog type resistivity-at-the-bit (GVR) and a high-resolution ring resistivity with a 7-in. depth of investigation. Three azimuthally focused 1-in. diameter buttons longitudinally spaced along the tool’s axis provide shallow, medium and deep depths of investigation of about 1, 3 and 5 in., respectively, for quantifying invasion profiles. These measurements are essential for interpreting and steering horizontal wells in complex reservoirs like Ewan where either the structural or stratigraphic risk (or both) is significant. In addition to the five resistivity measurements, the tool also acquires azimuthal gamma ray data, radial and lateral shock records, and temperature measurements. As the GVR tool operates in conductive water-based mud systems, the team ensured that proper salinity was achieved to improve its resistivity measurements. While drilling the Ewan-YH well, the deep button images and up and down resistivity, ring and bit resistivities as well as gamma ray up and down were transmitted while drilling with 6 bps mudpulse telemetry. Though the ROP exceeded 100 ft/hr (90 ft/hr ROP average), the resolution of the LWD logs were good to excellent. High ROP, coupled with RSS use, kept the average borehole size to 8.6 in., which helped prepare for the completion phase of the well. Resistivity-at-bit was used to restrict the well within the target sand while the real-time deep-button image and azimuthal resistivity aided in steering through the thin sand. The resistivity images were used continuously while drilling for dip interpretation, with subsequent trajectory adjustments made to place the well within the most productive sand. Along with the images, up and down deep resistivity measurements also enabled the geosteering team to stay in the “sweet spot” of the heterogeneous sandstone reservoir. Concurrent to resistivity data acquisition, permeability was estimated from the LWD NMR log, which was used to compute hydrocarbon producibility as a basis for determining optimal drill length. NMR technology provides critical reservoir parameters like effective porosity and permeability in real time – which traditional LWD tools cannot measure. The LWD NMR tool can be placed anywhere in the BHA with no detrimental effects to drilling operations. Highly programmable and extremely flexible, the tool’s acquisition modes allow a wide range of future acquisition sequence development. Typically, a multiple wait-time acquisition sequence is used. However, a fast, about 100 ft/hr ROP was expected for the Ewan-YH well, so a pulse sequence designed with a single longer initial wait-time of 12.5 seconds was used to completely polarize the oil productive intervals. Six bits per second data transmission was programed into the mudpulse telemetry tool for providing high quality real-time data despite the drillstring’s five tools and their large concurrent data transmissions. Update rate for all variables was 41 sec, enabling good real-time data at the expected ROPs. PILOT WELL DRILLING, GEOSTEERING LANDING The pilot hole was planned to evaluate reservoir thickness, permeability and placement of the well’s heel position. The plan for the drainhole section was adjusted to place it along formation strike (62E in NE direction). Previous sensitivity analysis on reservoir thickness, permeability and drainhole length run by engineering determined that a 5-ft thick target with a 1,200-ft lateral drainhole section was needed to meet productivity requirements. Upon entering the objective sand in the pilot hole, gamma ray decreased to 75 GAPI, resistivity increased to 8-10 ohm-m and the neutron porosity and density overlapped, showing that the objective sand was sufficiently thick with a 5-ft true vertical depth (TVD). NMR data in the pilot hole indicated up to 800-mD permeabilities midway through the sand, Fig. 2. While total porosity was about 25 rµ, the free fluid porosity was only 15 – 20 rµ. The early T2 arrivals indicated some shaliness, whereas the cleanest sand was found in the middle. The data confirmed that both permeability and thickness were sufficient to place a drain hole that would meet productivity targets.

Landing can be one of the most difficult aspects in horizontal drilling. The Ewan-YH heel position was targeted about 30 m away from the pilot well. The section above the target sand consisted mainly of shale, with no specific sand markers. The target sand was 3.2-ft TVD deeper than the pilot hole, so the landing also had to be deeper (by 3 ft) to position the heel midway through the sand. In past CNL examples, the team would go farther to attempt landing the well at 89E or 90E. During the landing, it was evident that the soft formation would result in drilling out the bottom of the thin sand when attempting to increase dogleg severity. The landing BHA assembly for the 12-1/4-in. hole was heavier and had to push against the formation for directional drilling changes. Upon entering the sand, the ability to increase inclination to achieve 90E inclination had diminished. The team decided to stop at 88E inclination, case and change-out the drilling assembly to drill the 8-1/2-in. lateral using alternate directional drilling technology. DRAINHOLE GEOSTEERING WITH RSS/ LWD TECHNOLOGIES As a result of the landing difficulties, the team decided to use an enhanced RSS system from Schlumberger, along with the GVR and LWD-NMR tools, for geosteering and later geostopping the Ewan-YH horizontal well. The PowerDrive Xceed* RSS has a steering assembly that continuously orients the tilted bit shaft to control drilling direction and borehole dogleg severity, also referred to as point-the-bit technology. In soft formations, the RSS is capable of developing dogleg severity as high as 8 ft/100 ft. The RSS tool does not push against the borehole to build angle, making it more effective in steering unconsolidated formations. This was the case in the Ewan target sand, where hole angle was in fact built with minimal dependence on the borehole for deflection. Xceed RSS is a fully rotating tool with no stationary external parts, which reduces the risk of sticking the pipe assembly. Moreover, penetration rates are improved because there are no stationary components to create friction, which reduces efficiency and anchors the BHA in the hole. While the tool looks and acts very much like a conventional drilling motor, it has the ability to adjust azimuth and inclination of the bit. After drilling out of casing, hole inclination dropped to 87.5E from casing and back reaming. As such, the dogleg severity was increased to 4 to 4.5. During the first 100-ft of lateral drilling, bit inclination was 90E, at which point geosteering via the GVR was initiated. Early on, the resistivity image showed downward progress stratigraphically in the sand, while button resistivity images indicated a calculated apparent up dip of 0.5E along the wellbore. Also, the NMR log showed poorer quality reservoir with early T2 arrivals, indicating silty sand having less free fluid volume. Therefore, it was decided to build to 91E to climb back up toward the middle of the sand. Drilling ahead, the well climbed midway to cleaner sand. The sample description indicated that sand content increased to 90% – 100% from 40%; sand grain size went from fine to medium; and resistivity measurements ranged between 9 and 12 ohms. However, after 25 ft within the clean sand, up resistivity decreased, indicating drilling was progressing upward. Dip interpretation from the resistivity image showed that the apparent dip was flattening out, so it was decided to level off at 90E inclination. Permeability estimates showed that the silty sand in the lower part had less than 100 mD permeabilities, but the middle lobe had higher permeabilities ranging from 300 mD to 1 Darcy. The FFVs increased when the well again approached the middle of the sand. Drilling on, resistivity images showed that the well was progressing along the top of the sand. The apparent dip had dropped to 1E down dip, so the inclination was decreased even more to 88.5E to drop down midway to cleaner sand. The apparent dip sustained at about 1.5E for the rest of the well and the inclination was maintained between 87E and 88E to follow the sand down dip. Here, permeabilities ranged from medium (200 to 300 mD) to high (300 mD up to 1 Darcy). However, in the heel of the well, or the first 200 ft, real-time productivity analysis using LWD-NMR images indicated poorer reservoir quality having low permeabilities (less than 100 mD), which prior reservoir simulation estimates showed was not sufficiently productive. Therefore, an additional 200 ft of drainhole section was extended from the planned TD, geosteered within medium to high permeability sand. The TD was declared after 1,400 ft of lateral section had been drilled from the landing point within the sand, Fig. 3. The well achieved its objective with 1,200 ft of productive sand.

During drilling of the 1,400-ft lateral section, a total of 15 adjustments called by geosteering staff were made. After 20 min., the change would be realized by geosteering staff via differences in tool read-out at the rig and geosteering work area. Average ROP was about 90 ft/hr, which was high in comparison to past CNL laterals drilled. However, GVR measurements provided the team with confidence to quickly and successfully navigate through the thin sand and complete the lateral section. The high ROP also prevented the ability of the BHA to produce washouts that can affect well completion, the Ewan-YH well having an average 8.6-in. diameter. GVR tool use limited completion type and equipment, so the Concentric Annual Production System (CAPS) was deployed in the well. Ewan field is known to produce sand when a wellbore first produces water. Consequently, sand control was deemed critical for this well’s production success. While the initial production estimate was 1,200 bopd, the actual IP was 1,600 bopd after bringing the well on production, exceeding expectations by 33%. Future tests will verify sustained well productivity. OVERVIEW AND FUTURE OUTLOOK The Ewan-YH well shows that it is feasible technically and economically to develop thinner sand targets through use of enhanced drilling technology, geosteering techniques and reservoir management. Attractive economic results were achieved for the well. More importantly, there are huge economic implications to CNL in light of its vast reserve potential in thin sand development. Lessons learned from Ewan-YH provide the beginning of a road map on how to reclassify CNL’s P2 and P3 reserves to P1 and increase its production. While near-bit azimuthal resistivity and images generated with the geoVISION downhole MWD/ LWD imaging services were essential for steering Ewan-YH within thin target sand, calculating dips and adjusting trajectory continuously, the proVISION LWD NMR tool proved vital for evaluating reservoir quality and estimating permeability in the shaly sand reservoir. Another case study, not included in this article, but discussed fully in the acknowledged SPE Paper No. 88889, used LWD NMR information to optimize a horizontal sidetrack in a highly permeable section of a reservoir that was also very thin. The Meji-4XH well, Meji field, offshore Nigeria, used the LWD NMR tool in both the pilot hole and the wellbore, which demonstrated that the horizontal section was placed generally within the most productive sand, or “sweet spot,” of high permeability and high free fluid, with production rates exceeding 2,200 bopd. This well illustrated that NMR acquisition using the LWD tool delivered near wireline quality data at ROP in excess of 200 ft/hr. This novel approach discussed in this article, combining best reservoir management practices with enhanced drilling technology and geosteering techniques using flexible LWD tools are key to future development of thin hydrocarbon reservoirs in the Niger Delta and around the world.

|

|||||||||||||||||||||||||||

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Drilling advances (January 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)