|

Vol. 226 No. 12 |

| |

|

Rig Floor Equipment

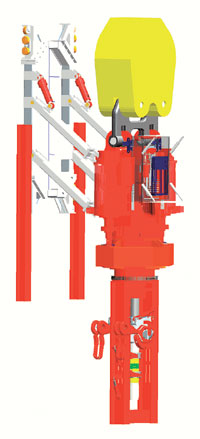

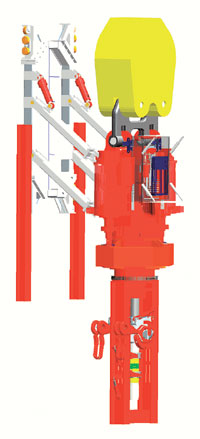

Next-generation top drive designed for 50,000 ft wells

Transocean has contracted Aker Kvaerner MH AS to provide a 1,250-ton Modular Derrick Drilling Machine (MDDM) intended initially for Transocean’s high-specification drilling rigs. The companies have put considerable effort into identifying the current and future limitations of available top drives and the related design and components.

|

Modularity of the MDDM can achieve savings through downtime prevention.

|

|

The MDDM will have 110% more horsepower than the 750-ton top drives developed for the 5th-generation offshore drilling rig fleet. In addition, it is designed to outperform current top drive life expectancy by 50% to 100%.

More importantly, the unit will play a pivotal role in clients’ increasingly aggressive well programs. In recent years, these programs have taken topdrives to their operational torque and hoisting limits. The equipment is used at design limits for much longer than originally intended, than when the 5th-generation fleet was launched from 1998 to 2001.

For Transocean’s Enterprise-class drillships, and for offline activity rigs, top drives are working 20% to 40% more during the same time period as a single-activity rig to save operational time. As a result, top drives now have higher failure rates, because they are working harder and wearing faster than ever before.

In addition, some operator programs require more torque and rotating load capacity than existing units can provide. The deepest offshore wells constructed to date have been about 35,000 ft in total depth, and future wells are expected to greatly exceed this limit, reaching as deep as 50,000 ft. To drill these wells efficiently and safely, a new machine with more capacity is required.

“The new MDDM design is radically different than the top drive systems that we have in place today on our rigs,” said Mike Hall, vice president, Engineering and Technical Services, for Transocean. “With improvements, such as redundancy of operation-critical components, capacity for increases in drilling load requirements and modularization to make quick repairs, this unit is expected to take one of the most important pieces of drilling equipment to the next level of performance for Transocean and our clients. We are creating spare capacity to be able to drill the wells that clients need today, and those that will be planned 10 to 20 years from today. If history holds true, these requirements will be more demanding than what today’s equipment can deliver. And we will be prepared to meet those needs.”

The modularity of the MDDM can achieve savings through downtime prevention, reducing repair time from days to a few hours. Other savings include reducing out-of-service time for overhauls and annual load path inspections, which can be done offline or during a rig move.

The new design enables maintenance operations from work platforms with easy access to components, and it will have designated lifting points, improving safety. Where possible, maintenance will be done off-line with an automated system.

The development project will be executed by Aker Kvaerner MH and based on best-practice project execution principles gained through several R&D projects, with key Transocean personnel contributing in all aspects of the project. Materials and components will be selected with quality and robustness as the main drivers. For key components like bearings, gearboxes and motors, the companies have defined separate programs to develop reliable solutions.

It is likely that lower-capacity models of the scalable top drive will emerge after the field test of the 1,250-ton prototype. As the MDDM is proven successful, Transocean expects to use it on other units. Transocean expects to install the prototype on a 5th-generation offshore rig in 1Q 2007.

|