|

Vol. 226 No. 4 |

AUV commissioned

Fugro’s Hugin 3000 Autonomous Underwater Vehicle (AUV), named “Echo Surveyor,” completed commissioning and final manufacturer’s acceptance tests at Kongsberg Maritime’s base in Horton, Norway. The AUV was tested as an integrated deepwater survey package with Fugro’s survey vessel M/V Geo Prospector acting as mothership. Echo Surveyor can be equipped with a range of payload sensors depending on the application or user needs. For deepwater survey, the standard is: EM2000 200-kHz multibeam echo-sounder; Edgetech full spectrum chirp seafloor mapping system comprising sidescan sonar and sub-bottom profiler; conductivity, temperature, depth system; and tightly coupled inertial navigation system Fugro’s Hugin 3000 Autonomous Underwater Vehicle (AUV), named “Echo Surveyor,” completed commissioning and final manufacturer’s acceptance tests at Kongsberg Maritime’s base in Horton, Norway. The AUV was tested as an integrated deepwater survey package with Fugro’s survey vessel M/V Geo Prospector acting as mothership. Echo Surveyor can be equipped with a range of payload sensors depending on the application or user needs. For deepwater survey, the standard is: EM2000 200-kHz multibeam echo-sounder; Edgetech full spectrum chirp seafloor mapping system comprising sidescan sonar and sub-bottom profiler; conductivity, temperature, depth system; and tightly coupled inertial navigation system

Reinjection system

Aberdeen-based DES Operations has launched new technology that enables increased production on oil- and gas-producing assets. The Multiple Application Reinjection System (MARS) enables oil and gas operators to optimize production while minimizing the risks and costs associated with well intervention. It is a universal interface that enables low-cost, low-risk processing, such as pumping, on new and existing subsea wells. Full wellbore intervention or flowline decommissioning and re-commissioning can be avoided, lowering the economic barriers to increased production. In the pumping scenario, MARS can be deployed on a subsea well system at any time during field life and will allow operators to increase production without well intervention or drilling risk. Although the company is currently focussed on pumping opportunities, MARS is a universal work platform which enables other subsea processing elements, such as separation or metering, to be simply deployed throughout the life of field. Early adoption allows flexibility to be designed into the field architecture, and it can be retrofitted onto any well.

|

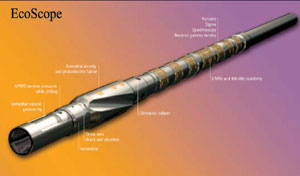

New while-drilling services

|

|

| |

Schlumberger introduced its new-generation Scope while-drilling services to improve drilling performance and well placement. According to the company, these set new standards for reliability and data quality, while quadrupling the data transmission rate over the industry standard. The three products comprising the Scope family are: EcoScope multifunction logging-while-drilling; StethoScope formation pressure-while-drilling; and TeleScope high-speed telemetry-while-drilling services.

The EcoScope multifunctional logging-while-drilling (LWD) service integrates drilling and formation evaluation sensors in one compact collar. These include key drilling measurements plus unique measurements such as elemental capture spectroscopy and sigma. EcoScope replaces the traditional AmBe source with a pulsed-neutron generator.

The StethoScope formation pressure-while-drilling service provides formation pressure measurements accurately and efficiently during drilling operations, in less time than needed to make a connection. Direct pore pressure and mobility data can be used for fluid typing, reservoir pressure management, and mud weight control and optimization to avoid kicks and drilling delays.

The TeleScope high-speed telemetry-while-drilling service, when used in conjunction with the Orion telemetry platform, increases data transmission rates fourfold, compared to the industry standard. The information that TeleScope delivers to surface provides a comprehensive picture of the downhole environment through real-time measurements from multiple tools.

|

|

|

|

|

|

Valve actuator

Rupture Pin Technology has developed the Buckling Pin Actuator, which can be mounted on most quarter-turn valves and used for pressure relief, emergency shutdown or flow diversion. With a full ported ball valve, there is very little pressure drop and the line can still be pigged. It is self-actuated and does not need electricity or an air supply for operation, and can be remotely located without operational failure. The actuator has a built-in clutch. The first 90° action is used to build up momentum so that the second 90° provides rapid valve action. Friction does not affect actuator set point, which can be set up to operate at high or low settings. The valve may be rapidly reset under pressure to prevent loss of product or production time. Rupture Pin Technology has developed the Buckling Pin Actuator, which can be mounted on most quarter-turn valves and used for pressure relief, emergency shutdown or flow diversion. With a full ported ball valve, there is very little pressure drop and the line can still be pigged. It is self-actuated and does not need electricity or an air supply for operation, and can be remotely located without operational failure. The actuator has a built-in clutch. The first 90° action is used to build up momentum so that the second 90° provides rapid valve action. Friction does not affect actuator set point, which can be set up to operate at high or low settings. The valve may be rapidly reset under pressure to prevent loss of product or production time.

Flow measurement in rugged environments

The new 8-page Oil & Gas Industry Flow Guide from Fluid Components International (FCI) is a quick reference tool that offers advice on air, gas and liquid measurement, monitoring and control techniques. The company’s precision thermal dispersion mass flow technology is a solution in a wide range of oil/gas operations, ranging from automated oil well testing to pump-off control to tanker loading/ unloading to chemical injection to flare gas measurement and much more.With a no-moving parts sensor design and no orifices to plug or foul, the company’s mass flow meters and flow/ level switches offer accurate, low maintenance measurement over a wide measurement range. Instruments are easy to install, and have long life and low lifecycle costs. The new 8-page Oil & Gas Industry Flow Guide from Fluid Components International (FCI) is a quick reference tool that offers advice on air, gas and liquid measurement, monitoring and control techniques. The company’s precision thermal dispersion mass flow technology is a solution in a wide range of oil/gas operations, ranging from automated oil well testing to pump-off control to tanker loading/ unloading to chemical injection to flare gas measurement and much more.With a no-moving parts sensor design and no orifices to plug or foul, the company’s mass flow meters and flow/ level switches offer accurate, low maintenance measurement over a wide measurement range. Instruments are easy to install, and have long life and low lifecycle costs.

Managed pressure drilling/ surface BOP combined

Transocean and Santos have combined the use of surface BOP technology and managed pressure drilling (MPD) methods on a semisubmersible rig working offshore Indonesia in a water depth of 2,240 ft. The achievement on the Transocean semisubmersible Sedco 601 was the first use of a rotating control head, which was produced by Weatherford, to control annulus pressure while drilling with a surface BOP from a floating rig. This combination of technologies enabled better control of the well while drilling through formations prone to total losses of circulation when drilled conventionally.

Nontoxic grease cleaner

Jep-14 is a non-toxic, biodegradable industrial cleaner and degreaser from Complete Environmental Products, Inc., that is suitable for any type of oil or grease application. The product is a water-based formula that encapsulates and emulsifies petroleum-based products, forming a special base surfactant that can be recovered. This blend of ingredients is formulated to work with tough hydrocarbon spills and can be used on floors, walls, machinery, sumps, hoods and other hard surfaces, and is recommended for oil platforms and pipeline cleaning. It is odorless, non-flammable, non-carcinogenic and contains no butyl or harsh solvents.

Viscoelastic surfactant

Schlumberger introduced its new ClearFRAC CO2 viscoelastic surfactant (VES) system, which extends polymer-free fluid technology to CO2 fracturing applications. The fracturing technique is generally used in deeper, lower quality and under-pressured reservoirs, which represent a larger portion of reservoirs requiring stimulation as fields mature and higher quality reservoirs become less abundant. Long effective fracture half-length is key to maximizing return on investment in tight gas fracturing operations. ClearFRAC CO2 accomplishes this with a robust, stable nature and the superior clean-up characteristic of solids-free VES fracturing fluids. It also reduces the propensity for height growth, thus increasing fracture length in the pay zone. An extension of the Schlumberger ClearFRAC family of VES fracturing fluids, the ClearFRAC CO2 formulation incorporates a fit-for-purpose surfactant package that addresses the complexities of stabilizing the supercritical CO2.

Geologic modeling software

Earth Decision Sciences has released version 2.1.2 of its Well Correlation and Stratigraphic Analysis Module, a suite of comprehensive tools for interpreting, displaying, and performing QC of geologic data in a flexible 2-D environment. Integrated with the other applications in the Earth Decision Suite, this version allows the user to perform rapid and accurate interpretations of geologic structures and stratigraphy to construct a consistent geological model. Data can be viewed in single or multi-well views, and cross sections.

Acquire impact loading data

Data Stem from RC Technology is a memory impact system capable of monitoring and recording forces applied to wireline operations. By utilizing force sensing technology in wireline toolstring, the operator can accurately identify the actual impact loads created downhole. Data from the impact-sensing module can be downloaded at the surface to a PC, where analysis of downhole impact loads are compared to actual forces applied at surface from the wireline unit. This way, an optimum toolstring configuration can be implemented, ensuring accurate and suitable forces are applied at depth to retrieve or install a specific system. Data Stem removes the need, in many applications, for a separate gauge run in the wellbore to acquire pressure and temperature logs. The tool does not impact the structural strength of the system, and has been tested to ensure compatibility with impact jars with up to 105,000 lb impact force.

Seismic imaging upgrade

TGS Imaging has released a new version of the PRIMA pre-stack interpretation and analysis software. Release highlights for version 7.0 include new interpretation tools and features, functionality improvements, well log overlay capabilities and enhanced workflow integration. The release adds a new “Interactive Surface Viewer by Offset” tool for improved gather attribute displays. Gather attributes can be submitted as a batch job to optimize computational delays. the new version can display and overlay well paths and curves in certain modules. Several other enhancements were made to increase task efficiency.

|

Fugro’s Hugin 3000 Autonomous Underwater Vehicle (AUV), named “Echo Surveyor,” completed commissioning and final manufacturer’s acceptance tests at Kongsberg Maritime’s base in Horton, Norway. The AUV was tested as an integrated deepwater survey package with Fugro’s survey vessel M/V Geo Prospector acting as mothership. Echo Surveyor can be equipped with a range of payload sensors depending on the application or user needs. For deepwater survey, the standard is: EM2000 200-kHz multibeam echo-sounder; Edgetech full spectrum chirp seafloor mapping system comprising sidescan sonar and sub-bottom profiler; conductivity, temperature, depth system; and tightly coupled inertial navigation system

Fugro’s Hugin 3000 Autonomous Underwater Vehicle (AUV), named “Echo Surveyor,” completed commissioning and final manufacturer’s acceptance tests at Kongsberg Maritime’s base in Horton, Norway. The AUV was tested as an integrated deepwater survey package with Fugro’s survey vessel M/V Geo Prospector acting as mothership. Echo Surveyor can be equipped with a range of payload sensors depending on the application or user needs. For deepwater survey, the standard is: EM2000 200-kHz multibeam echo-sounder; Edgetech full spectrum chirp seafloor mapping system comprising sidescan sonar and sub-bottom profiler; conductivity, temperature, depth system; and tightly coupled inertial navigation system

Rupture Pin Technology has developed the Buckling Pin Actuator, which can be mounted on most quarter-turn valves and used for pressure relief, emergency shutdown or flow diversion. With a full ported ball valve, there is very little pressure drop and the line can still be pigged. It is self-actuated and does not need electricity or an air supply for operation, and can be remotely located without operational failure. The actuator has a built-in clutch. The first 90° action is used to build up momentum so that the second 90° provides rapid valve action. Friction does not affect actuator set point, which can be set up to operate at high or low settings. The valve may be rapidly reset under pressure to prevent loss of product or production time.

Rupture Pin Technology has developed the Buckling Pin Actuator, which can be mounted on most quarter-turn valves and used for pressure relief, emergency shutdown or flow diversion. With a full ported ball valve, there is very little pressure drop and the line can still be pigged. It is self-actuated and does not need electricity or an air supply for operation, and can be remotely located without operational failure. The actuator has a built-in clutch. The first 90° action is used to build up momentum so that the second 90° provides rapid valve action. Friction does not affect actuator set point, which can be set up to operate at high or low settings. The valve may be rapidly reset under pressure to prevent loss of product or production time.  The new 8-page Oil & Gas Industry Flow Guide from Fluid Components International (FCI) is a quick reference tool that offers advice on air, gas and liquid measurement, monitoring and control techniques. The company’s precision thermal dispersion mass flow technology is a solution in a wide range of oil/gas operations, ranging from automated oil well testing to pump-off control to tanker loading/ unloading to chemical injection to flare gas measurement and much more.With a no-moving parts sensor design and no orifices to plug or foul, the company’s mass flow meters and flow/ level switches offer accurate, low maintenance measurement over a wide measurement range. Instruments are easy to install, and have long life and low lifecycle costs.

The new 8-page Oil & Gas Industry Flow Guide from Fluid Components International (FCI) is a quick reference tool that offers advice on air, gas and liquid measurement, monitoring and control techniques. The company’s precision thermal dispersion mass flow technology is a solution in a wide range of oil/gas operations, ranging from automated oil well testing to pump-off control to tanker loading/ unloading to chemical injection to flare gas measurement and much more.With a no-moving parts sensor design and no orifices to plug or foul, the company’s mass flow meters and flow/ level switches offer accurate, low maintenance measurement over a wide measurement range. Instruments are easy to install, and have long life and low lifecycle costs.