|

Belgium, Germany, Spain |

|

3D CAD/ CAM software for steel detailing and fabrication

|

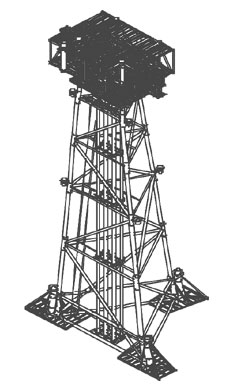

Example Bocad-3D platform design output.

|

|

Bocad-3D, from Belgium’s Bocad Service International (BSI), is computer software dedicated to any kind of structural steel detailing and fabrication, including buildings, factories, power plants, bridges, towers, oil rig platforms, tanks and ducting. Using the latest technology, the system allows building projects in 3D, then automatically controlling the 3D model to attribute a reference number (piece mark) to each component. This can further generate all bills of material, weight control reports and all necessary drawings, weld maps for project fabrication, including profiles cutting plan and numerical control machine data.

There is an international library of beams, bolts/ welding, a dynamic link between 3D model and drawings, and automatic update of all drawings and materials, in case of revision. These offer the possibility of saving the operator’s own standard connections inside a library.

The possibility to load a 3D model from analysis software into Bocad-3D, and export a model to other disciplines, makes it possible to build only one structural-steel 3D model used in all of the disciplines. This same 3D model built by the engineering consultants is used by the steel fabricator to extract all fabrication drawings and numerical control machine data, and can be reviewed by clients. Drawings can be given to subcontractors in Autocad .dxf, or directly in .dwg, and all bill of materials in ASCII or Excel format.

Mainly the result of teamwork with customers and the high technology of the oil/gas industries, the software has a specific package to build oil and gas platforms, such as drilling, production and riser/ satellite platforms, bridges, jackets, main support frames, modules, flare booms, boat landings, helidecks and piping supports. In this package, a full range of oil/gas standard connections, members, 2D elements, macros and tools all speed up the 3D modeling of oil rigs to fit offshore-specific output requirements. Major cost-saving factors include accuracy guarantee, short time frame, waste material reduction and revision control.

|