New Bit Designs

ReedHycalog

Improved bi-center bits tackle smaller hole sizes

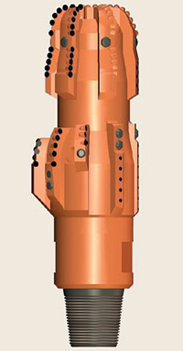

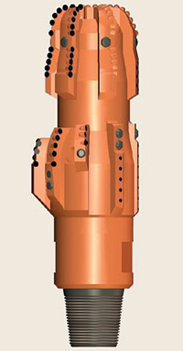

DPI-ReedHycalog has developed an improved bi-center bit for small hole sizes (9-7/8 in. and smaller) and is currently named a speed reamer, casing-shoe-driller, CSD+, bi-center bit. The goal was to make improvements in bi-center bits, such as less angle drop in tangent sections, increased resistance to string vibrations, and generally better dull conditions. The initial CSD+ design consisted of a pilot and reamer section that was similar to standard CSD designs, but a mid-reamer was added between the pilot and reamer. The concept behind this change is called geometric stability.

To produce a mid-reamer that works properly in small-hole bi-center bits, there needs to be a significant difference between the pilot and reamer diameters. As the bi-center bit gets smaller, the difference between the pilot and reamer diameters becomes less, leaving no room for a proper mid-reamer between the two sections. Recently, DPI-ReedHycalog began looking at a new design, where the mid-reamer was repositioned to become part of the pilot (see figure). As a result, the benefit of the mid-reamer was retained while producing a pilot that is effectively larger in diameter, without compromising steerability.

|

|

Fig. 1. The new, double-profile pilot 8-1/2 x 9-1/2 CSD+322 drilled 1,220 ft at about 28 fph in South Texas., This was the area's best bi-center run.

|

|

Fig. 2. In a field run, the Bi-Center CSD+344 and V-Stab drilled the interval, replacing three bits and an underreamer.

|

|

The new, double-profile pilot 8-1/2 x 9-1/2 CSD+322 was just run in South Texas. It drilled the entire interval (1,220 ft) at about 28 fph, resulting in the best bi-center run in the area. Previous CSD runs in the same area exhibited pilot damage. The improved bi-center bit came back with the cutting structure in excellent condition.

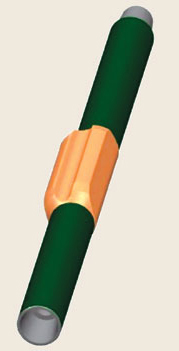

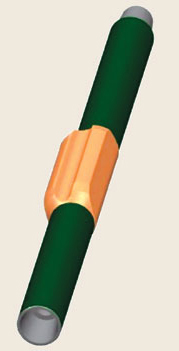

Two-bladed, full-hole stabilizer has no moving parts

DPI-ReedHycalog has also developed a two-bladed, full-hole stabilizer for bi-center drill bits. The V-Stab has no moving parts and is designed using bi-center geometry. Use of bi-center geometry allows the stabilizer to pass through a smaller hole, yet stabilize the string in a larger hole, reducing the detrimental effects of string vibrations.

Normally, when stabilizers are used with a bi-center bit, the maximum stabilizer diameter is the pass-through (casing drift) size. When string vibrations occur, an undersized stabilizer can move in all directions, but it does help reduce how far the string can move in any direction. Since the V-Stab has two blades that are at the full-hole diameter (the third blade is missing and does allow string movement to one side of the hole), string movement in the opposite direction is prevented. This reduces the effects of the string vibrations, and can result in longer bit runs, bit life, and increased ROP.

Bi-center bit runs with the V-Stab have demonstrated improved ROP and significant improvements in bit life. In a specific field run, a CSD+344 bi-center bit and a V-Stab drilled the entire interval, replacing three bits and an under-reamer from a direct offset. Where vibration data have been obtained, the vibrations are low compared to offset bi-center runs and, in some cases, lower than conventional drill bit runs.

|