|

Vol. 225 No. 11 |

Industrial engine balancer

Dynalco introduced the new BETA-TRAP3 Power Cylinder Balancer, a cost-effective tool for measuring and adjusting peak firing pressures (PFP) and detecting combustion problems on industrial engines. The BETA-TRAP3 displays average, standard deviation, maximum and minimum power cylinder peak firing pressures of each engine cylinder all at once. Pressure-time patterns can also be viewed to identify power cylinder problems. Under 3 lb, yet robust in design, it is virtually immune to the effects of open ignition secondaries and uses coefficient of variance (COV) across the engine to assist in reducing emissions associated with unstable combustion.

|

New version of closed-loop-control drilling system

|

|

| |

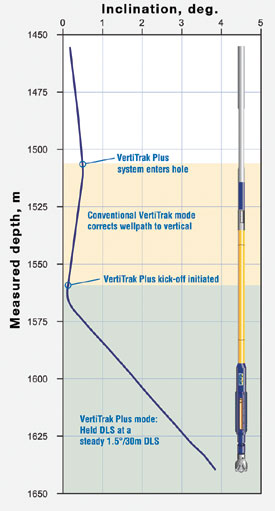

The VertiTrak Plus system from Baker Hughes INTEQ allows drillers to drill a true vertical well down to the kick-off point as on standard VertiTrak applications, and then begin building angle without setting casing or tripping out of the hole. VertiTrak systems perform closed-loop steering using downhole inclination sensors and expandable stabilizer pads designed to counteract a formation's natural buildup tendency. Local doglegs are minimized and a high-quality, in-gauge hole without ledges or offsets is provided throughout the entire run. Because string rotation is not required to improve hole cleaning in low-angle wells, VertiTrak systems are designed to run in sliding mode without string rotation to minimize damaging vibrations and string/ casing wear. The combination of a cased kick-off and the non-rotating VertiTrak Plus system minimizes the possibility of key seats in the curve and reduces friction and wear in later hole sections.

The system was used to drill the 16-in. hole section on Alli3 OR well for operator ENI Divisione E & P in Val D'Agri oilfield in southern Italy. The system was run in the hole at 1,506 m (4,941 ft) and corrected the existing wellpath back to vertical in less than 50 m (164 ft). After drilling down to 1,560 m (5,118 ft), a downlink was sent from the surface to the tool to initiate the kick-off mode. An MWD tool above the VertiTrak Plus device provided the required azimuth measurements for the kick-off. The system then built up inclination at a steady rate of 1.5°/30 m until a 280° azimuth and 5° target inclination was achieved. The section was completed with a single run, and 133/8-in. casing was run to a depth of 1,644 m (5,394 ft).

|

|

|

|

|

|

Casing drilling brochure

Grant Prideco, Inc., has developed a brochure outlining its improved casing drilling system. Drilling With Casing (DWC) technology is a special connection for casing drilling applications that provides sound economics, high resistance to cyclic torsional loads, superior sealing capability while subjected to dramatic cyclic loads, enhanced fatigue resistance and field-friendly running procedures. This family of semi-premium connections is designed to meet the conditions seen with casing drilling technology and meets all requirements dictated by the emerging casing connection marketplace. Grant Prideco, Inc., has developed a brochure outlining its improved casing drilling system. Drilling With Casing (DWC) technology is a special connection for casing drilling applications that provides sound economics, high resistance to cyclic torsional loads, superior sealing capability while subjected to dramatic cyclic loads, enhanced fatigue resistance and field-friendly running procedures. This family of semi-premium connections is designed to meet the conditions seen with casing drilling technology and meets all requirements dictated by the emerging casing connection marketplace.

Twin-shaft grinders

The Moyno Series 4 Annihilator grinder is now equipped with high-performance cutters for greater cutting efficiency. The twin-shaft solids-reduction unit includes spacer cutters for improved cutting efficiency, providing double the number of cutting edges compared to other grinders. It utilizes bi-directional cutting teeth on the spacers as well as the cutters to prevent fibrous material binding or seizing of the machine. The toothed cutting spacers increase the unit's efficiency, further decreasing particle size and reducing the risk of failure from ragging. The Series 4 Annihilator grinders include the standard five-tooth reversible cutter on the drive shaft and a seven-tooth reversible cutter on the idler shaft. Other cutter combinations are also available for specific applications.

Broadband networking in remote locations

Schlumberger Information Solutions (SIS) has expanded its satellite services portfolio. The new IPerformer and IPresence services are the latest addition to the SIS suite of IPoVSAT – Internet Protocol over Very Small Aperture Terminal – network solutions. IPerformer offers clients a dedicated network infrastructure that is flexible and can be tailored to specific needs. The IP-oriented architecture provides security and performance for business-critical applications, such as real-time data delivery. The IPresence service allows clients to share satellite bandwidth and terrestrial infrastructure in a secure and efficient manner. It supports voice and data services at a fraction of the cost of typical dedicated architecture systems without impacting either the integrity of the underlying technologies or client data.

Expert drilling service/software

Drillworks Expert Service from Knowledge Systems is a knowledge-based, real-time solution that combines Drillworks Services' expertise with Drillworks 2005 technology to give operators a 1,000-ft look ahead of the bit. Geopressure and geomechanics experts at the wellsite integrate all seismic, petrophysical and geologic analysis and bring geopressure prediction to the basin scale for a more accurate analysis. The service incorporates real-time compartment pressure analysis and wellbore stability analysis to help optimize mud and casing programs.

Drillworks 2005 software suite is an integrated geopressure and geomechanics solution that includes: Drillworks Pressbase database, a relational database that allows operators to store and manage geopressure-related data; Drillworks Explorer, which provides an intelligent window into the large amount of data an operator accumulates and converts it into an asset for future planning; Drillworks Uncertainty Analysis which allows operators to perform uncertainty analysis on geopressure and geomechanics predictions; Drillworks Leak Off Test Analyzer, which enables full pressure/ volume/ time plots from a leak-off test to be solved for minimum stress and populate pore pressure and wellbore stability models; and Drillworks Real Time Drilling Optimization Center, which enables establishment of a monitoring center for surveillance of multiple wells drilled anywhere in the world.

Insertable downhole pump

The Insertable Progressing Cavity (IPC) Pump System from R&M Energy Systems allows downhole installation and retrieval without pulling the production tubing. The system provides operational reliability and flexibility, reducing overall life-cycle costs. The pumps can handle a wide range of artificial-lift conditions, including low- and high-viscosity fluids and solids transport in oilfield and coalbed methane dewatering applications. The system allows flushing operations without disengaging the pump from the seated position, and the landing nipple is the only component attached to the tubing string at the bottom of the hole. The pumps can be installed in 2-7/8-in. to 5-1/2-in.-diameter tubing. No special tools are required for installation. The Insertable Progressing Cavity (IPC) Pump System from R&M Energy Systems allows downhole installation and retrieval without pulling the production tubing. The system provides operational reliability and flexibility, reducing overall life-cycle costs. The pumps can handle a wide range of artificial-lift conditions, including low- and high-viscosity fluids and solids transport in oilfield and coalbed methane dewatering applications. The system allows flushing operations without disengaging the pump from the seated position, and the landing nipple is the only component attached to the tubing string at the bottom of the hole. The pumps can be installed in 2-7/8-in. to 5-1/2-in.-diameter tubing. No special tools are required for installation.

Digital positioners

Flowserve Corp., a provider of fluid motion and control products and services, introduced the Logix 3200IQ and 500si series digital positioners. The devices offer quick setup and calibration of either diaphragm- or piston-operated valves without the need for additional handheld devices, software or configuration/calibration tools. The explosion-proof Logix 3200IQ and the intrinsically safe 500si series use piezo technology and inner-loop feedback to provide high performance, control and reliability with minimal air consumption in compact, lightweight and modular designs. The series is available in two models – the 510si for the analog market and the 520si, which uses the HART communication protocol. Flowserve Corp., a provider of fluid motion and control products and services, introduced the Logix 3200IQ and 500si series digital positioners. The devices offer quick setup and calibration of either diaphragm- or piston-operated valves without the need for additional handheld devices, software or configuration/calibration tools. The explosion-proof Logix 3200IQ and the intrinsically safe 500si series use piezo technology and inner-loop feedback to provide high performance, control and reliability with minimal air consumption in compact, lightweight and modular designs. The series is available in two models – the 510si for the analog market and the 520si, which uses the HART communication protocol.

Continuous temperature sensor

SensorTran, a provider of temperature-sensing equipment to the oil and gas industry, announced the availability of the SensorTran 5100, a Distributed Temperature Sensing (DTS) Instrument. It is a new technology that turns ordinary optical fiber into a continuous temperature sensor, allowing permanent real-time monitoring over the entire length of a well. The product can measure out to 10 km with a 1°C temperature resolution, and operates in ambient conditions from 0°C to 40°C.

Tripping/casing-running tool

The new T/KT tool from W-N Apache imparts the top drive's full torque and rotating speed ranges to casing, drilling and production tubulars that are being added to or removed from the drillstring. The tool does the work of an elevator, and within the limits of the top drive's maximum torque, also performs as an upper breakout/ make-up tool and spinner. The T/KT is typically equipped with pin thread that matches the tubulars being run. This provides the means for quickly killing a kick when tripping pipe or running casing, and eliminates the need to make up and break out both ends of each tubular when going into or out of the hole.

Natural gas measurement

EMS Pipeline Services, a pipeline operations and maintenance service provider, introduced PGAS 6.1, an upgrade to PGAS, the widely accepted standard in natural gas measurement systems. The flexible and open architecture of PGAS 6.1 gives users more control over how data is gathered, validated, edited, reported and disseminated. Developed on the scalable Microsoft.Net development platform, the software offers greater scalability, reliability and security. Improvements in Version 6.1 include an enhanced import process using an open XML interface; improved validation capabilities to flag errors or anomalies; improved gas-balancing features to reduce lost gas; a new summarization capability calculating hourly, daily and monthly totals; a new Audit View function that facilitates compliance with Sarbanes-Oxley; and other regulations, among others.

Pipeline measurement

Baker Hughes Pipeline Management Group (PMG) introduced a new in-line pipeline inspection tool. The PMG MFLCal is a single system that acquires both high-resolution metal loss (magnetic flux leakage) and caliper data sets simultaneously. The tool's ability to pass bore restrictions more severe than most existing caliper pigs (25% of OD in most cases) largely eliminates the need for bore prove-up by stand-alone caliper. The MFLCal offers 1.5D bend (back-to-back) capability, shorter tool length, and extended run times.

|

Grant Prideco, Inc., has developed a brochure outlining its improved casing drilling system. Drilling With Casing (DWC) technology is a special connection for casing drilling applications that provides sound economics, high resistance to cyclic torsional loads, superior sealing capability while subjected to dramatic cyclic loads, enhanced fatigue resistance and field-friendly running procedures. This family of semi-premium connections is designed to meet the conditions seen with casing drilling technology and meets all requirements dictated by the emerging casing connection marketplace.

Grant Prideco, Inc., has developed a brochure outlining its improved casing drilling system. Drilling With Casing (DWC) technology is a special connection for casing drilling applications that provides sound economics, high resistance to cyclic torsional loads, superior sealing capability while subjected to dramatic cyclic loads, enhanced fatigue resistance and field-friendly running procedures. This family of semi-premium connections is designed to meet the conditions seen with casing drilling technology and meets all requirements dictated by the emerging casing connection marketplace. The Insertable Progressing Cavity (IPC) Pump System from R&M Energy Systems allows downhole installation and retrieval without pulling the production tubing. The system provides operational reliability and flexibility, reducing overall life-cycle costs. The pumps can handle a wide range of artificial-lift conditions, including low- and high-viscosity fluids and solids transport in oilfield and coalbed methane dewatering applications. The system allows flushing operations without disengaging the pump from the seated position, and the landing nipple is the only component attached to the tubing string at the bottom of the hole. The pumps can be installed in 2-7/8-in. to 5-1/2-in.-diameter tubing. No special tools are required for installation.

The Insertable Progressing Cavity (IPC) Pump System from R&M Energy Systems allows downhole installation and retrieval without pulling the production tubing. The system provides operational reliability and flexibility, reducing overall life-cycle costs. The pumps can handle a wide range of artificial-lift conditions, including low- and high-viscosity fluids and solids transport in oilfield and coalbed methane dewatering applications. The system allows flushing operations without disengaging the pump from the seated position, and the landing nipple is the only component attached to the tubing string at the bottom of the hole. The pumps can be installed in 2-7/8-in. to 5-1/2-in.-diameter tubing. No special tools are required for installation. Flowserve Corp., a provider of fluid motion and control products and services, introduced the Logix 3200IQ and 500si series digital positioners. The devices offer quick setup and calibration of either diaphragm- or piston-operated valves without the need for additional handheld devices, software or configuration/calibration tools. The explosion-proof Logix 3200IQ and the intrinsically safe 500si series use piezo technology and inner-loop feedback to provide high performance, control and reliability with minimal air consumption in compact, lightweight and modular designs. The series is available in two models – the 510si for the analog market and the 520si, which uses the HART communication protocol.

Flowserve Corp., a provider of fluid motion and control products and services, introduced the Logix 3200IQ and 500si series digital positioners. The devices offer quick setup and calibration of either diaphragm- or piston-operated valves without the need for additional handheld devices, software or configuration/calibration tools. The explosion-proof Logix 3200IQ and the intrinsically safe 500si series use piezo technology and inner-loop feedback to provide high performance, control and reliability with minimal air consumption in compact, lightweight and modular designs. The series is available in two models – the 510si for the analog market and the 520si, which uses the HART communication protocol.