|

Vol. 225 No. 5 |

Biodegradable fracing fluid

Baker Oil Tools developed B9 Emerald FRAQ, a fracturing fluid that combines superior performance with low toxicity and biodegradability, and is especially suited for offshore use. The product meets and exceeds current Gulf of Mexico offshore permitted waste fluid discharge regulations for “well treatment fluid” standards set by the EPA, specified in the Code of Federal Regulations, 40 CFR Part 435. With less than 29 mg/l of hexane extractable material, HEM, oil and grease content, it satisfies the EPA's definition of “oil and gas free” for well-treating fluids. The EPA regulations do not establish a discharge permit standard for toxicity for well treatment fluids, but with the B9 Emerald FRAQ fluid systems' very low toxicity (less than 3%) the fluid also meets and exceeds the 40 CFR Part 435 standards set for drilling fluids, and it biodegrades more than 60% in 28 days. Baker Oil Tools developed B9 Emerald FRAQ, a fracturing fluid that combines superior performance with low toxicity and biodegradability, and is especially suited for offshore use. The product meets and exceeds current Gulf of Mexico offshore permitted waste fluid discharge regulations for “well treatment fluid” standards set by the EPA, specified in the Code of Federal Regulations, 40 CFR Part 435. With less than 29 mg/l of hexane extractable material, HEM, oil and grease content, it satisfies the EPA's definition of “oil and gas free” for well-treating fluids. The EPA regulations do not establish a discharge permit standard for toxicity for well treatment fluids, but with the B9 Emerald FRAQ fluid systems' very low toxicity (less than 3%) the fluid also meets and exceeds the 40 CFR Part 435 standards set for drilling fluids, and it biodegrades more than 60% in 28 days.

Casing cutting system

Designed to support installation of unitized wellhead designs, the EICC accommodates a broad range of standard Casing ODs and IDs and sets up in as little as 30 min. Each system is furnished with an OD-mounted split-frame casing cutter, an ID internal casing cutting attachment and a wellhead adapter, built to client-provided dimensions of the wellheads make and model, and all required accessories in a single package. Seized casing is easily cut and removed using the internal cutting attachment. The EICC is then equipped with chamfer tooling for precision machining of the casing relief angle required for the casing remaining below the flange. Designed to support installation of unitized wellhead designs, the EICC accommodates a broad range of standard Casing ODs and IDs and sets up in as little as 30 min. Each system is furnished with an OD-mounted split-frame casing cutter, an ID internal casing cutting attachment and a wellhead adapter, built to client-provided dimensions of the wellheads make and model, and all required accessories in a single package. Seized casing is easily cut and removed using the internal cutting attachment. The EICC is then equipped with chamfer tooling for precision machining of the casing relief angle required for the casing remaining below the flange.

Wiper plug indicator

Allamon Tool Co. introduced the Wiper Plug Indicator Sub, a device that corrects the cement displacement error normally encountered on long casing and liner strings. The WPI, comprising a non-metallic core specially bonded to a casing pup, is normally run 30 to 50 bbl above the auto-fill float collar. When the casing plug lands in the WPI, it presents the cementer a 700 to 1,000-psi pressure spike on the cement unit. This permits an adjustment to be made in displacement, giving a more efficient shoe track.

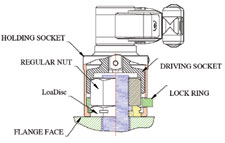

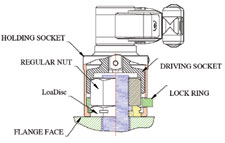

Compression washer

Joint failure is often the result of incorrect and uneven bolt load, which can be traced back to the limitations of hydraulic torque tools and tensioners, both of which are subject to critical unknowns. LoaDISC is a compression washer from HYTORC that is the same size as the regular nut connect to the bolt thread. When placed underneath a regular hex nut, the compression washer stops the stud from turning and thus creates axial bolt elongation with no side load. The LoaDISC also helps the hex nut and the bolt achieve and retain the bolt load within an accuracy of ±10%. The standard material of the washer is Grade 7H. Holding the bolt-thread-connected washer stationary with a holding socket, while turning the nut on top of it, results in a counter-nut effect, which stops the tooling as well as the bolt from turning along with the nut. Further nut-turning stretches the bolt, which pulls up the inner thread segment of the LoaDISC according to the bolt elongation until the desired bolt load is achieved within 10% of setting. Joint failure is often the result of incorrect and uneven bolt load, which can be traced back to the limitations of hydraulic torque tools and tensioners, both of which are subject to critical unknowns. LoaDISC is a compression washer from HYTORC that is the same size as the regular nut connect to the bolt thread. When placed underneath a regular hex nut, the compression washer stops the stud from turning and thus creates axial bolt elongation with no side load. The LoaDISC also helps the hex nut and the bolt achieve and retain the bolt load within an accuracy of ±10%. The standard material of the washer is Grade 7H. Holding the bolt-thread-connected washer stationary with a holding socket, while turning the nut on top of it, results in a counter-nut effect, which stops the tooling as well as the bolt from turning along with the nut. Further nut-turning stretches the bolt, which pulls up the inner thread segment of the LoaDISC according to the bolt elongation until the desired bolt load is achieved within 10% of setting.

Rig for shallow gas

Precision Drilling Corp. introduces a new generation of shallow drilling rigs that are an alternative to coiled tubing drilling, suited for the shallow-gas market. The Precision Super Single Light is a scaled-down version of the original Super Single rig. The automated pipe-handling system and the integrated top drive have been incorporated to ensure that the rig is efficient and safe. Use of conventional Range III jointed tubulars gives it an advantage over coiled tubing. In coiled tubing applications, factors such as wellbore diameter and lithology can create situations where coiled tubing does not perform well, but the Super Single Light is never compromised regardless of the drilling application. Precision Drilling Corp. introduces a new generation of shallow drilling rigs that are an alternative to coiled tubing drilling, suited for the shallow-gas market. The Precision Super Single Light is a scaled-down version of the original Super Single rig. The automated pipe-handling system and the integrated top drive have been incorporated to ensure that the rig is efficient and safe. Use of conventional Range III jointed tubulars gives it an advantage over coiled tubing. In coiled tubing applications, factors such as wellbore diameter and lithology can create situations where coiled tubing does not perform well, but the Super Single Light is never compromised regardless of the drilling application.

Casing drilling brochure

A new publication from Grant Prideco details the advantages, field history and technical specifications of its family of DWC connections. Studies have shown a 20 – 30% reduction in time required from spud to rig release when drilling with casing is used. Initially, casing drilling used traditional connections, but these exhibited sealing problems due to high cyclic-torsion loads. DWC connections offer an optional seal ring groove that provides a seal for the life of the string, unlike thread seal that relies on solids in the thread compound. Featured are the DWC/C and DWC/C-SR models, which incorporate a torque-shouldering system developed for casing drilling operations, the DWC/DS and DWC/DS-SR models for greater stability in the bottomhole assembly, and the DWC/U and DWC/U-SR models, designed for upset pipe.

Olefin drilling fluid

Amodrill from BP is an olefin drilling fluid that biodegrades faster than oil-based fluids, while providing a number of other environmental improvements, including lower toxicity. Bioassays conducted over a three-month period showed better seed germination and total degradation for the Amodrill, compared to samples containing the oil-based fluids. At the same time, the olefin-based sample had zero levels of earthworm toxicity after 90 days. Data also show that Amodrill muds convert to CO 2 and water by-products and biomass, which enriches the soil. Calculated to total biodegradation time, wells drilled with Amodrill-based muds biodegrade in two to three years, less than half the time it takes for wells drilled with oil-based muds. Other environmental benefits of the synthetic fluid include: reduced exposure to fugitive emissions of aromatic compounds, low volatility, high flash points (above 100°C), and less odor.

Remote indicator

Emerson Process Management announces the Rosemount 752 Remote Indicator, which provides multi-function display on Foundation fieldbus segments. Adding to the breadth of PlantWeb digital plant architecture functions, the Rosemount 752 makes it possible to display data from intelligent field devices throughout the plant. The Rosemount 752 has ATEX intrinsically safe approval and FISCO certification to enable efficient use with devices and displays installed in hazardous areas. The device can connect and sequentially display up to eight function block values from any device on an H1 segment. Each plant measurement or reading is shown for 3 seconds, along with a tag identifier and the engineering units. Applications for the 752 Indicator include the display at grade level of data from any instrument mounted in an inaccessible location.

Wireless data acquisition

AnTech Ltd has launched DAQ>W, a new data-acquisition system capable of transmitting data wirelessly from the well site. The system is comprised of a network of sensors connected to a battery-powered transmitter that is ATEX-certified for use in Zone 0 hazardous areas. As data measurements are acquired, they are transmitted at regular intervals to the base station in the control cabin. Readings are then immediately displayed via custom DAQ>W software on the base station. Internal batteries power the transmitter boxes that can last up to 10 years, and the base units can be powered by any 9-36Vdc supply, so it even runs efficiently from a car battery. The system avoids the danger of lost data acquisition caused by damage to power cables.

Well cleanout system

Schlumberger Oilfield Services introduces a new approach to well cleanout with its multicomponent PowerCLEAN. Designed for wellbore fill removal using coiled tubing, the PowerCLEAN system is an integrated solution that includes job design software, a proprietary nozzle design for improved cleaning ability, specialized fluids, and a real-time solids-monitoring system to detect solids as they are removed to the surface. This new service enables optimum cleanout of sand, bauxite and similar particles under virtually any wellbore condition, including large casing, high-temperature and any deviation angle. Conventional cleanout nozzles have a forward or forward-backward jetting action that can leave debris in the wellbore. This new system uses a swirling effect to create a fluid vortex that carries removed particles up the wellbore. A low-friction fluid allows the system to achieve higher flowrates without increased pumping pressure.

Impeller brochure

Chemineer has released a new brochure entitled “Advanced Impeller Technology for Superior Performance,” that details the company's many precision-engineered impeller designs. This four-page, full-color bulletin provides information on Chemineer's latest impeller advancements, such as the SC-3, the Maxflo W and the Maxflo WSE. It also details Chemineer's main line of impeller designs, such as the HE-3, the S-4 and P-4, as well as high-viscosity impeller options like the Double Helical Ribbon and the Anchor impellers. The Maxflo WSE side-entering impeller design, featuring a high-efficiency hydrofoil for maximum pumping action, is also included. These are more cavitation resistant than other designs and feature bolted blades for easy maintenance. Also featured are gas-dispersion impellers, such as the D-6, CD-6 and the latest BT-6, that give peak performance in gas-dispersion applications. Chemineer's new Smoothline impeller design is also highlighted, a configuration featuring liquid-shedding surfaces and concealed hardware for enhanced CIP performance and greater cleanability. Chemineer has released a new brochure entitled “Advanced Impeller Technology for Superior Performance,” that details the company's many precision-engineered impeller designs. This four-page, full-color bulletin provides information on Chemineer's latest impeller advancements, such as the SC-3, the Maxflo W and the Maxflo WSE. It also details Chemineer's main line of impeller designs, such as the HE-3, the S-4 and P-4, as well as high-viscosity impeller options like the Double Helical Ribbon and the Anchor impellers. The Maxflo WSE side-entering impeller design, featuring a high-efficiency hydrofoil for maximum pumping action, is also included. These are more cavitation resistant than other designs and feature bolted blades for easy maintenance. Also featured are gas-dispersion impellers, such as the D-6, CD-6 and the latest BT-6, that give peak performance in gas-dispersion applications. Chemineer's new Smoothline impeller design is also highlighted, a configuration featuring liquid-shedding surfaces and concealed hardware for enhanced CIP performance and greater cleanability.

|

Baker Oil Tools developed B9 Emerald FRAQ, a fracturing fluid that combines superior performance with low toxicity and biodegradability, and is especially suited for offshore use. The product meets and exceeds current Gulf of Mexico offshore permitted waste fluid discharge regulations for “well treatment fluid” standards set by the EPA, specified in the Code of Federal Regulations, 40 CFR Part 435. With less than 29 mg/l of hexane extractable material, HEM, oil and grease content, it satisfies the EPA's definition of “oil and gas free” for well-treating fluids. The EPA regulations do not establish a discharge permit standard for toxicity for well treatment fluids, but with the B9 Emerald FRAQ fluid systems' very low toxicity (less than 3%) the fluid also meets and exceeds the 40 CFR Part 435 standards set for drilling fluids, and it biodegrades more than 60% in 28 days.

Baker Oil Tools developed B9 Emerald FRAQ, a fracturing fluid that combines superior performance with low toxicity and biodegradability, and is especially suited for offshore use. The product meets and exceeds current Gulf of Mexico offshore permitted waste fluid discharge regulations for “well treatment fluid” standards set by the EPA, specified in the Code of Federal Regulations, 40 CFR Part 435. With less than 29 mg/l of hexane extractable material, HEM, oil and grease content, it satisfies the EPA's definition of “oil and gas free” for well-treating fluids. The EPA regulations do not establish a discharge permit standard for toxicity for well treatment fluids, but with the B9 Emerald FRAQ fluid systems' very low toxicity (less than 3%) the fluid also meets and exceeds the 40 CFR Part 435 standards set for drilling fluids, and it biodegrades more than 60% in 28 days. Designed to support installation of unitized wellhead designs, the EICC accommodates a broad range of standard Casing ODs and IDs and sets up in as little as 30 min. Each system is furnished with an OD-mounted split-frame casing cutter, an ID internal casing cutting attachment and a wellhead adapter, built to client-provided dimensions of the wellheads make and model, and all required accessories in a single package. Seized casing is easily cut and removed using the internal cutting attachment. The EICC is then equipped with chamfer tooling for precision machining of the casing relief angle required for the casing remaining below the flange.

Designed to support installation of unitized wellhead designs, the EICC accommodates a broad range of standard Casing ODs and IDs and sets up in as little as 30 min. Each system is furnished with an OD-mounted split-frame casing cutter, an ID internal casing cutting attachment and a wellhead adapter, built to client-provided dimensions of the wellheads make and model, and all required accessories in a single package. Seized casing is easily cut and removed using the internal cutting attachment. The EICC is then equipped with chamfer tooling for precision machining of the casing relief angle required for the casing remaining below the flange. Joint failure is often the result of incorrect and uneven bolt load, which can be traced back to the limitations of hydraulic torque tools and tensioners, both of which are subject to critical unknowns. LoaDISC is a compression washer from HYTORC that is the same size as the regular nut connect to the bolt thread. When placed underneath a regular hex nut, the compression washer stops the stud from turning and thus creates axial bolt elongation with no side load. The LoaDISC also helps the hex nut and the bolt achieve and retain the bolt load within an accuracy of ±10%. The standard material of the washer is Grade 7H. Holding the bolt-thread-connected washer stationary with a holding socket, while turning the nut on top of it, results in a counter-nut effect, which stops the tooling as well as the bolt from turning along with the nut. Further nut-turning stretches the bolt, which pulls up the inner thread segment of the LoaDISC according to the bolt elongation until the desired bolt load is achieved within 10% of setting.

Joint failure is often the result of incorrect and uneven bolt load, which can be traced back to the limitations of hydraulic torque tools and tensioners, both of which are subject to critical unknowns. LoaDISC is a compression washer from HYTORC that is the same size as the regular nut connect to the bolt thread. When placed underneath a regular hex nut, the compression washer stops the stud from turning and thus creates axial bolt elongation with no side load. The LoaDISC also helps the hex nut and the bolt achieve and retain the bolt load within an accuracy of ±10%. The standard material of the washer is Grade 7H. Holding the bolt-thread-connected washer stationary with a holding socket, while turning the nut on top of it, results in a counter-nut effect, which stops the tooling as well as the bolt from turning along with the nut. Further nut-turning stretches the bolt, which pulls up the inner thread segment of the LoaDISC according to the bolt elongation until the desired bolt load is achieved within 10% of setting. Precision Drilling Corp. introduces a new generation of shallow drilling rigs that are an alternative to coiled tubing drilling, suited for the shallow-gas market. The Precision Super Single Light is a scaled-down version of the original Super Single rig. The automated pipe-handling system and the integrated top drive have been incorporated to ensure that the rig is efficient and safe. Use of conventional Range III jointed tubulars gives it an advantage over coiled tubing. In coiled tubing applications, factors such as wellbore diameter and lithology can create situations where coiled tubing does not perform well, but the Super Single Light is never compromised regardless of the drilling application.

Precision Drilling Corp. introduces a new generation of shallow drilling rigs that are an alternative to coiled tubing drilling, suited for the shallow-gas market. The Precision Super Single Light is a scaled-down version of the original Super Single rig. The automated pipe-handling system and the integrated top drive have been incorporated to ensure that the rig is efficient and safe. Use of conventional Range III jointed tubulars gives it an advantage over coiled tubing. In coiled tubing applications, factors such as wellbore diameter and lithology can create situations where coiled tubing does not perform well, but the Super Single Light is never compromised regardless of the drilling application. Chemineer has released a new brochure entitled “Advanced Impeller Technology for Superior Performance,” that details the company's many precision-engineered impeller designs. This four-page, full-color bulletin provides information on Chemineer's latest impeller advancements, such as the SC-3, the Maxflo W and the Maxflo WSE. It also details Chemineer's main line of impeller designs, such as the HE-3, the S-4 and P-4, as well as high-viscosity impeller options like the Double Helical Ribbon and the Anchor impellers. The Maxflo WSE side-entering impeller design, featuring a high-efficiency hydrofoil for maximum pumping action, is also included. These are more cavitation resistant than other designs and feature bolted blades for easy maintenance. Also featured are gas-dispersion impellers, such as the D-6, CD-6 and the latest BT-6, that give peak performance in gas-dispersion applications. Chemineer's new Smoothline impeller design is also highlighted, a configuration featuring liquid-shedding surfaces and concealed hardware for enhanced CIP performance and greater cleanability.

Chemineer has released a new brochure entitled “Advanced Impeller Technology for Superior Performance,” that details the company's many precision-engineered impeller designs. This four-page, full-color bulletin provides information on Chemineer's latest impeller advancements, such as the SC-3, the Maxflo W and the Maxflo WSE. It also details Chemineer's main line of impeller designs, such as the HE-3, the S-4 and P-4, as well as high-viscosity impeller options like the Double Helical Ribbon and the Anchor impellers. The Maxflo WSE side-entering impeller design, featuring a high-efficiency hydrofoil for maximum pumping action, is also included. These are more cavitation resistant than other designs and feature bolted blades for easy maintenance. Also featured are gas-dispersion impellers, such as the D-6, CD-6 and the latest BT-6, that give peak performance in gas-dispersion applications. Chemineer's new Smoothline impeller design is also highlighted, a configuration featuring liquid-shedding surfaces and concealed hardware for enhanced CIP performance and greater cleanability.