MWD/LWD-Formation Evaluation

Advances in MWD and formation evaluation for 2004

Developments include new CD- and Web-based resources; centralized drilling operations center; wireline and while-drilling logging methods; mud log measurements; formation pressures while drilling; and coring and analysis technology.

David Patrick Murphy, Shell International EP Inc., Houston

The latest advances in formation evaluation, especially data acquisition while drilling, are improving quality and increasing the quantity of formation data, while reducing costs and making operations more efficient. Some of those advances discussed here include:

- General – Historical well log interpretation charts, new rock catalog and drilling operations center

- Wireline logging – Triaxial induction, NMR, imaging, cased hole evaluation, new logging platform and wireline tool jars

- MWD/LWD – NMR steering and formation resistivity

- Mud logging – Wellsite mud gas isotope analysis and cuttings NMR

- Testing – LWD formation pressure measurements

- Coring and Analyses – Logging while coring, pore structure imaging and outcrop permeability.

|

Fig. 1. Denver Well Logging Society seven-CD compilation of historical well log interpretation charts from 1947 to 1999.1

|

|

GENERAL

Historical well log interpretation charts assist evaluation of wells with legacy well log data. Rock catalogs provide analog rock data. Drilling operations and well evaluation can benefit from more effective, real-time collaboration and integration between operations, engineering and geoscience staff.

Historical chart CDs. The Denver Well Logging Society has assembled a seven-CD compilation of historical well log interpretation charts from 1947 to 1999, Fig. 1.1 This collection includes four CDs of Schlumberger chart books and interpretation handbooks dating back to Document 1. Two CDs cover charts from Baker Atlas, predecessor companies PGAC and Lane Wells, plus companies acquired by Atlas such as Birdwell. And there is one CD of Halliburton charts including predecessor companies Welex and Gearhart. The complete set is list priced at US$149 from AAPG, RMAG, SEG and SPWLA.

Rock catalog. The Kansas Geological Society (KGS) has developed a rock catalog for stand-alone use or for integrated use with its online GEMINI (Geo-Engineering Modeling through INternet Informatics) reservoir evaluation software.2 Rock catalogs are designed to provide analog rock property information when limited rock descriptions are available.

The GEMINI rock catalog contains information concerning porosity, permeability, lithology, grain density, capillary pressure, and electrical/ mechanical properties. KGS has built in capability to expand and modify its rock database as needed. Selected core data can be shown by itself, compared to other core data via crossplots and histograms, or shown with core photos and well logs. GEMINI funding was provided by the US Department of Energy. It can be accessed free of charge from KGS at www.kgs.ku.edu/Gemini/.

Drilling center. Halliburton has developed and installed a visualization, telecommunication, and data-sharing network and well monitoring system to assist offshore operations from an operator's office on a continual basis.3 The drilling center's objective is to improve safety, reduce offshore travel, reduce drilling cost, improve geosteering, and improve integration between people charged with drilling/ evaluating the well. Offshore drilling supervisor operational control is supplemented with increased collaboration and integration between onshore and offshore resources and expertise. Drilling center components include a well monitoring area, and conference/ collaboration and visualization rooms. MWD/LWD drilling operations and formation evaluation information can be securely transmitted and updated to the drilling center and other operator intranet sites about every 1 ft of drilling.

WIRELINE LOGS

Wireline logs typically provide more formation evaluation wellbore data for lower cost than other tools, except when rig costs are very high.

Triaxial induction. Schlumberger has completed field testing of a new experimental triaxial induction tool to provide tensor formation resistivity information.4 The tool is fully triaxial, with sensors measuring all combinations of transmitter and receiver orientations at the same point and at the same time. Conventional induction tools measure only horizontal resistivity. Availability of both horizontal and vertical resistivities allows determination of formation resistivity anisotropy like that caused by thinly laminated hydrocarbon- bearing sand- shale sequences.

Petrophysical evaluation using the additional vertical resistivity measurement provides improved hydrocarbon saturation estimates over those using only horizontal resistivity. Triaxial tools are also sensitive to formation geometry, dip and azimuth; providing additional potential formation evaluation insights in the future.

NMR. Three new tools have been developed by Baker Atlas, Computalog and Halliburton-NUMAR.

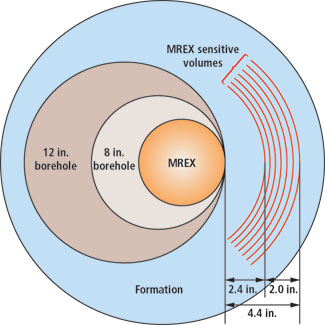

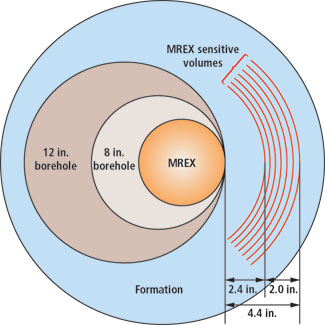

MR Explorer (MREX) is Baker Atlas' new multifrequency, multiple magnetic- field- gradient, side- looking, wireline NMR tool, Fig. 2. Multiple frequencies allow single- logging- pass acquisition of multiple echo trains with different acquisition parameters, providing a more complete data set.5 Multiple gradients are used for diffusion- based hydrocarbon typing or quantification. The side- looking design reduces environmental effects of salt-saturated muds, allows logging in large diameter boreholes, and eliminates centralization issues in deviated and horizontal wells.

|

Fig. 2. Side-looking MREX concept, cross-section of the tool on a typical wellbore. Courtesy www.bakerhughes.com/bakeratlas/formation-evaluation/mrex-benefits.

|

|

The tool's depth of investigation varies from 2.5 in. to 4.5 in. away from the borehole wall, depending on the operating frequency, making it tolerant to borehole wall irregularities. The company's objective- oriented acquisition approach uses pre-defined acquisition parameters based on reservoir hydrocarbon type and formation rock property objectives, which reduces the amount of pre-logging planning.

Computalog has field tested a new NMR logging tool designed and lab-characterized by NPR “Karatozh.”6 The Nuclear Magnetic Resonance Tool (NMRT) is a multifrequency tool capable of operating at three frequencies with a center frequency of about 730 kHz and a spread of 24 to 30 kHz. The centralized tool probes an annular volume of investigation with a diameter of 13.8 in. and thickness on the order of 0.028 in. NMRT can function with various pulse sequences to measure a variety of reservoir parameters. Several prototype tool versions have been assembled and tested.

Halliburton-NUMAR has tested a new NMR directional resonance sensor geometry suitable for wireline and LWD deployment.7 Initial tests were performed on a wireline prototype. The company's current Magnetic Resonance Imaging Log (MRIL) utilizes multiple concentric cylindrical ring volumes of investigation. The new sensor breaks these volumes into four azimuthally distinguishable quadrants. A wireline tool with this sensor geometry reduces environmental effects of salt-saturated muds, allows logging in large diameter boreholes, and eliminates centralization issues in deviated and horizontal wells. The wireline version typically acquires data in 10 different volumes, staggered in five different depths of investigation ranging from 2.5 in. to 4 in., making it tolerant to borehole wall irregularities.

Imaging log. Halliburton's Extended Range Micro-Imager (XRMI), a modification of its Electrical Micro-Imager (EMI), was introduced during 2003 with worldwide deployment now in progress.8 XRMI was designed to produce high fidelity images where Rt /Rm ratios are very high, such as in high resistivity formations with Rt greater than 2,000 ohm-m, or in very salty borehole fluids with Rm less than 0.1 ohm-m.

Siliciclastic evaluation. Schlumberger's DecisionXpress service integrates data from its Platform Express and ECS Elemental Capture Spectroscopy tools.9 In the new system, ECS elemental yield information provides siliciclastic mineralogy and matrix properties parameters that are used by the Platform Express triple combo for matrix- corrected porosity, water saturation and permeability estimate.

Cased hole. Cased hole formation evaluation applications include:

- Evaluation of wells having limited or no openhole logs due to hole problems

- Re-evaluation of old wells that were drilled before logs became quantitative

- Reservoir monitoring for fluid contact movement, and saturation/ pressure changes

- Evaluation of wells drilled with casing.

Schlumberger's Analysis Behind Casing (ABC) service provides cased- hole evaluation for porosity, bulk density, lithology, water saturation, acoustic properties, permeability estimation, formation pressure and formation fluid samples.10 Available tools include:

- CHFR-Plus Cased Hole Formation Resistivity for formation resistivity

- CHDT Case Hole Dynamics Tester for formation pressures and fluid samples

- CHFP Cased Hole Formation Porosity tool for neutron porosity and sigma

- CHFD Cased Hole Formation Density tool which uses a new characterization of a density device specifically for cased hole

- DSI Dipole Shear Sonic Imager tool for formation acoustic velocity information.

Wireline jars. Halliburton has commercially deployed a multi-conductor electric wireline jar.11 LockJar, developed by Evans Engineering Inc., features a mechanical lock that prevents inadvertent triggering during logging operations. A hydraulic time delay allows actuation at any load above the mechanical lock and is not sensitive to changes in borehole pressure or temperature. The jar, placed immediately above wireline log or formation test tools, can be activated as many times as necessary to remove a stuck tool.

Wireline logging system. Baker Atlas has introduced the FOCUS wireline logging system12 including a shorter, lighter logging tool string; the system includes:

- FOCUS HDIL High-Definition Induction Log array induction resistivity

- FOCUS ZDL Compensated Z-Densilog spectral density

- FOCUS CN Compensated Neutron porosity

- FOCUS DAL Digital Acoustilog monopole array acoustic

- FOCUS GR Gamma Ray which provides correlation at high logging speeds.

FOCUS sensors are designed to log at speeds up to 60 ft/min without reducing accuracy or precision. An accelerometer aligned along the long axis of the tool string can be used to make corrections to surface depth estimates.

MWD/LWD

Formation evaluation tool suites for these applications are providing additional measurements and more accurate versions of existing measurements.

|

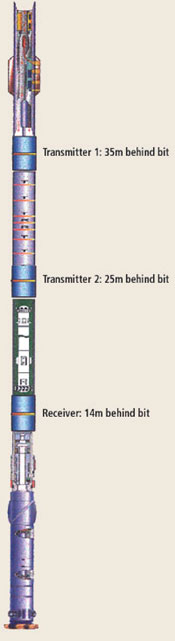

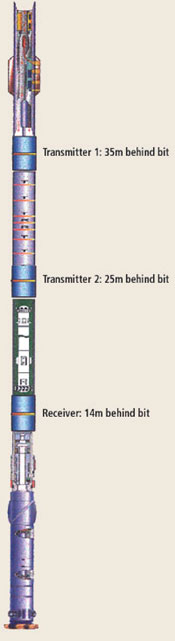

Fig. 3. Bottomhole assembly with Schlumberger deepVISION Resistivity (LWD) modular subs. In this example, transmitter and receiver distances are 11 m and 21 m.16

|

|

NMR and steering tool. Schlumberger's ProVISION real-time LWD reservoir steering tool13 provides NMR data for information about pore fluid type, porosity, permeability and bound fluid volume. This real-time producibility information can be used to drive steering decisions, allowing well trajectory to be directed to highly permeable zones. Irreducible water saturation information can be used to avoid water-productive zones. ProVISION can be placed anywhere in the BHA without detrimental effects on the drilling operation; and it can be run stabilized or slick.

Resistivity. Three different LWD resistivity tool configurations are discussed.

Geolink (UK) Ltd. offers its TRIM LWD 20kHz induction resistivity measurement.14 Depth of investigation is similar to that of a wireline deep induction log, which is deeper than conventional higher- frequency LWD resistivity logs. TRIM is equipped with azimuthal measurement capability which has application in geosteering operations.

Halliburton has developed a new multi-frequency, multi-spacing LWD resistivity tool, EWR-M5, capable of measuring resistivities at multiple radial depths of investigation.15 The company has developed a new approach to process and display LWD resistivity data at fixed depths of investigation to match those typically used for wireline array induction tools, and provide a meaningful way of comparing wireline array induction and while- drilling multi- spacing resistivity data.

Schlumberger has introduced deepVISION Resistivity (VDR), an ultra-deep resistivity measurement for geosteering, Fig. 3.16 VDR consists of separate subs with the standard configuration of two transmitters and one receiver which can be placed anywhere in the LWD tool string. From each transmitter- receiver pair, multi- frequency induction amplitude measurements at 2, 10, and 100 kHz are acquired and transmitted to surface in real time. The number, order and spacing of the subs are flexible, and can be optimized to obtain the desired radial sensitivity and proximity to the bit. Tool distance to geologic boundary computation is based on full inversion of the acquired measurements.

A reservoir model is assembled from offset well logs and seismic interpretation, incorporating a number of parameters including resistivity and thickness of the reservoir layers. For each parameter, a range of possible values is defined to take into account variation of reservoir properties along the well path. By modeling theoretical tool response for every possible combination of parameter values, including tool position within the model, a log response table is assembled and stored in memory. Once this database is built, analytical code can simulate tool response for any number of alternatives with minimal computational effort.

MUD LOGGING

This technology provides nearly real time information concerning lithology, rock properties and pore fluid types. Two new systems are described here.

Laser gas isotope. Westport is field testing its Automated Real-time Methane Isotope System (ARMIS), an automated, laser- based, flow- through isotope measurement system for measuring carbon and deuterium isotopes on methane in the mud gas stream at the wellsite.17 Applications include pay detection, determining gas association with liquids, interwell correlation and reservoir communication. ARMIS data and interpretations can be categorized as follows:

- Real-time: Methane concentration, C1 carbon isotopes, C1 deuterium isotopes, thermogenic gas proportion and depth of thermogenic source. These data assist making real-time decisions such as whether to test specific zones.

- Immediate data for extended studies: Interwell correlation, reservoir communication, and source correlation. These studies, which require interpretation with previous data from the area, can be done immediately rather than waiting for lab isotope data.

- Combined drilling- acquired and production- acquired isotope information: Commingled production allocation, production efficiency from non-producing zone identification, and production hardware performance monitoring.

ARMIS can be integrated with Westport's new Mudgas Onsite Sampling and Transport (MOST) system that captures mud gas samples for transport to an offsite lab for more detailed analysis. The integration allows gas samples to be optimally selected for gas type and concentration based on ARMIS data. Then fewer total samples need to be captured and analyzed, and those that are captured should be high-quality and most important for well evaluation.

NMR on cuttings. KMS Technologies has added Magnetic Resonance for Mud Logging (MR-ML) to its product line.18 The system is based on low field NMR measurements and is intended for fast and reliable identification of hydrocarbon- bearing reservoirs from drill cuttings and small hydrocarbon samples circulated to surface while drilling. It is a compact system with magnet and electronics in a single case. NMR Plus of Canada has provided applications software, including porosity and permeability estimation. Rock property estimation depends on the cuttings containing pores, which can be problematic in unconsolidated sediments. Fully water- saturated rock cuttings are preferred for NMR permeability evaluation.

TESTING

Quick formation pressure measurement over multiple zones has advanced from wireline to LWD. Drilling time formation pressure measurements can be done before borehole degradation and in time to optimize the drilling process, and have the following applications:

- Data acquisition from extended reach horizontal wells without time-consuming, pipe-conveyed wireline runs

- Early detection of high-pressure zones

- Pressure-based well steering

- Hydrocarbon typing and fluid contact determination from pressure gradients

- Reservoir permeability estimates

- Leak-off tests.

LWD formation testers. Two new LWD formation test tools provide formation pressure information.

Halliburton Sperry-Sun has introduced its GeoTAP formation tester, Fig. 4, to measure in-situ subsurface formation pressure on demand during pauses in drilling.19 Pressure tests are achieved in 5 to 10 min., depending on formation permeability. By use of a closed hydraulic system, battery power and quartz plus redundant strain gauges, the sensor extends a probe on command, establishes a seal at the borehole wall, and then performs a drawdown/ build-up sequence to measure formation pressure which is stored to memory and transmitted to a surface data unit for analysis and use in real time.

|

| |

Fig. 4. Halliburton's GeoTAP formation pressure while drilling tool collar showing the packer/ probe and equalization valve. While drilling or tripping, the packer/ probe is protected in a recessed portion of the collar.19

|

|

|

GeoTAP reservoir pressure measurement can be made with pumps on or off. Standard pressure range is up to 18,000 psi with a high pressure option up to 22,500 psi. Drawdown pressure differential can be up to 5,000 psi. In addition to being a multiple-set formation pressure tool, it can measure borehole pressure while drilling.

Baker Hughes has field tested TesTrak, its new formation pressure testing-during-drilling tool.20 During a brief drilling pause, the tool extends a pad-sealing element against the borehole wall to measure formation pressure. Its design allows basic pressure tests with preset drawdown and build-up tests with preset fixed volume and rates, or repeated drawdown and build-up test with different drawdown rates and volumes optimized downhole in real time. The system is equipped with an intelligent control system based on the developer's Formation Rate Analysis (FRA) algorithms that control the drawdown pump.

CORING AND ANALYSES

This technology provides rock for direct measurement of rock properties. Logging while coring and two innovative analysis methods are discussed.

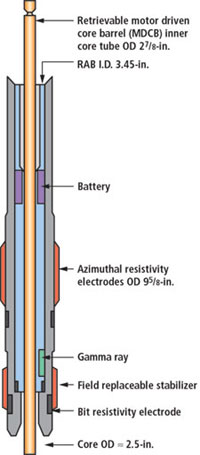

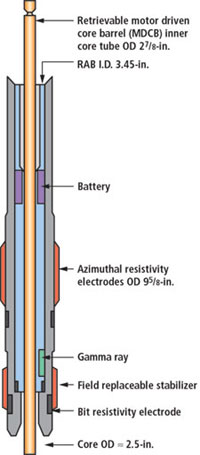

Logging while coring. A jointly-developed system was deployed and tested during Ocean Drilling Program (ODP) Leg 204 on Hydrate Ridge off the coast of Oregon, Fig. 5.21 It comprised two existing devices modified to be used together: a Schlumberger Resistivity-at-Bit tool and a Texas A&M University wireline retrievable, motor- driven core barrel. Resistivity and gamma ray well log and resistivity image data were recorded in downhole memory for post processing. Continuous wireline- retrievable coring is routine in nearly all ODP drill holes, whereas industry coring programs are often limited in key intervals due to time and cost constraints. LWD and wireline logging runs are typically made following coring in all ODP holes. Logging while coring is an example of more effective formation evaluation data acquisition.

|

| |

Fig. 5. Logging while coring system developed for the ODP using Texas A&M and Schlumberger technology. Motor- driven core barrel, depicted in yellow, passes through modified Schlumberger RAB collar to allow acquisition of resistivity/ gamma ray data while collecting full core.21

|

|

|

3D rock imaging. Lawrence Berkeley National Laboratory has applied Focused Ion Beam (FIB) technology to achieve submicron- resolution 3D pore images of very small pore systems, such as those found in diatomite and chalk.22 FIB is used to mill away rock sample surface layers as wide as 50 µ and as thin as 100 nm. As a new surface is exposed after each milling step, a 2D image of the surface is generated using secondary electrons or ions to obtain image resolutions as fine as 10 nm. The series of 2D images is digitally stacked and the 3D pore structure is reconstructed using appropriate interpolation and surface rendering algorithms.

FIB technology has been used extensively in microelectronics during IC prototype design. It also has been used in material sciences to prepare thin samples for use in Transmission Electron Microscopy (TEM). In earth sciences, its previous use has been in preparing samples for TEM or to access inner regions for performing microanalysis.

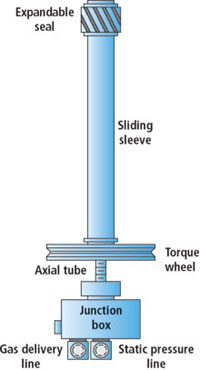

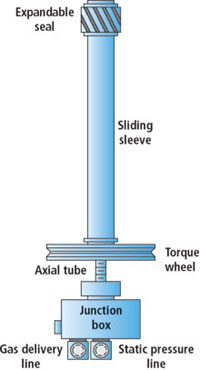

Outcrop drill hole permeameter. Clemson University has developed an innovative technique for measuring outcrop permeability in situ, below the weathered surface, Fig. 6.23 Small diameter holes (1.8 cm) are drilled into an outcrop with a masonry drill, followed by drillhole vacuuming. A mini- permeameter probe is inserted into the drill hole and its seal is expanded. The probe then injects gas into the outcrop. Measurement of injection pressure and gas flowrate, combined with system geometry knowledge, allows calculation of intrinsic permeability.

|

| |

Fig. 6. Clemson- developed small- drillhole mini- permeameter probe for measuring outcrop permeability without surface weathering effects. Rotating torque wheel clockwise moves sliding sleeve toward expandable seal, causing seal to axially compress and radially expand.23

|

|

|

A single probe has been durable enough to make thousands of measurements in a variety of environments. For best data accuracy, the mini- permeameter is NIST-calibrated before and after use. Directly after initial NIST (national standard) calibration, permeability of a portable ceramic check source is measured. Then, the ceramic check source can be tested daily in the field prior to data collection to verify that the entire system is working properly.

ACKNOWLEDGEMENT

The author thanks Shell International Exploration and Production Inc. for permission to publish this article. And technical details and insight provided by organizations and companies whose technology is discussed in this article are gratefully appreciated.

LITERATURE CITED

1 Denver Well Logging Society, Historical Chart Books on CD-ROM, http://dwls.spwla.org/chart_books.htm, August 2003.

2 Kansas Geological Society, Rock Catalog Tutorial, http://www.kgs.ukans.edu/Gemini/Help/RockCat/rocktutorial.html, July 2003.

3 Herbert, M., et al., “A step change in collaborative decision making – Onshore drilling center as the new work space,” SPE Annual Technical Conference and Exhibition, Transactions, SPE Paper 84167, October 2003.

4 Rosthal, R., et al., “Field test results of an experimental fully- triaxial induction tool,” SPWLA 44th Annual Symposium, Transactions, Paper QQ, June 2003.

5 Chen, S., et al., “MR Explorer log acquisition methods: Petrophysical- objective- oriented approaches,” SPWLA 44th Annual Symposium, Transactions, Paper ZZ, June 2003.

6 Khamatdinov, R., et al., “Field test of a new nuclear magnetic resonance tool,” SPWLA 44th Annual Symposium, Transactions, Paper AAA, June 2003.

7 Prammer, M., et al., “Directional resonance: New applications for MRIL,” SPE Annual Technical Conference and Exhibition, Transactions, SPE Paper 84479, October 2003.

8 Halliburton, “XRMI X-tended Range micro imager tool,” SPE Annual Technical Conference and Exhibition, Theater Two: Well construction and formation evaluation, October 2003.

9 Schlumberger, “ DecisionXpress petrophysical evaluation system,” http://www.oilfield.slb.com/content/services/formation/petrophysics/decisionxpress.asp, September 2003.

10 Schlumberger, ABC analysis behind casing, Brochure FE_03_002_0, July 2003.

11 Halliburton, Multi-conductor wireline Jars-LockJar, http://www.halliburton.com/oil_gas/sd0097.jsp, 2004.

12 Baker Atlas, FOCUS – An introduction to FOCUS accuracy and efficiency, 2003.

13 Schlumberger, proVISION, Brochure SMP-8173, February 2003.

14 Geolink (UK) Ltd., “ TRIM resistivity system,” http://www.geolink.co.uk/productlisting.html#TRIM resistivity logging system, 2004.

15 Bittar, M., et al., “Fixed depth of investigation log for LWD resistivity tool,” SPE Annual Technical Conference and Exhibition, Transactions, SPE Paper 84098, October 2003.

16 Iverson, M., et al., “Geosteering using ultradeep resistivity on the Grane field, Norwegian North Sea,” SPWLA 44th Annual Symposium, Transactions, Paper J, June 2003.

17 Elrod, L., “Automated real-time methane isotope system,” SPE Annual Technical Conference and Exhibition, Westport Technology Center international booth, October 2003.

18 KMS Technologies and NMR Plus of Canada, Magnetic resonance for mud logging, http://www.kmstechnologies.com/KMS_Entry/KMS_Tech_Overview/mr-ml.htm, December 2003.

19 Proett, M., et al., “Formation testing while drilling, a new era in formation testing,” SPE Annual Technical Conference and Exhibition, Transactions, SPE Paper 84087, October 2003.

20 Frank, S., et al., “Field experience with a new formation pressure testing- during- drilling tool,” IADC/SPE Drilling Conference, Transactions, IADC/SPE Paper 87091, March 2004.

21 Goldberg, D., et al., “Logging- while- coring – New technology advances scientific drilling,” SPWLA 44th Annual Symposium, Transactions, Paper CC, June 2003.

22 Tomutsa, L., and Radmilovic, V., “ Focused ion beam assisted three- dimensional rock imaging at submicron scale,” http://www.osti.gov/bridge/product.biblio.jsp?osti_id=812456, May 2003.

23 Dinwiddie, C., et al., “The new small- drillhole minipermeameter probe for in-situ permeability measurement,” SPE Annual Technical Conference and Exhibition, Transactions, SPE Paper 84595, October 2003.

THE AUTHOR

|

|

David Patrick Murphy is senior staff petrophysical engineer for Shell International EP Inc. He is also formation evaluation lecturer for the University of Houston graduate program in petroleum engineering. Mr. Murphy is a licensed professional engineer in Texas, Oklahoma, Louisiana and California.

|

| |

|

|